Acknowledged for making it easy for all to “Live Lightly™”, Native Shoes 3D Printed two of its most popular footwear designs.

The Canadian footwear company collaborated with MIT’s Self-Assembly Lab to fabricate the shoes. Together, they experimented an unusual design named Liquid Printed Natives. The brand’s cofounder, Thomas Claypool, says they’re always looking for “cutting edge and futuristic methods of manufacture.”

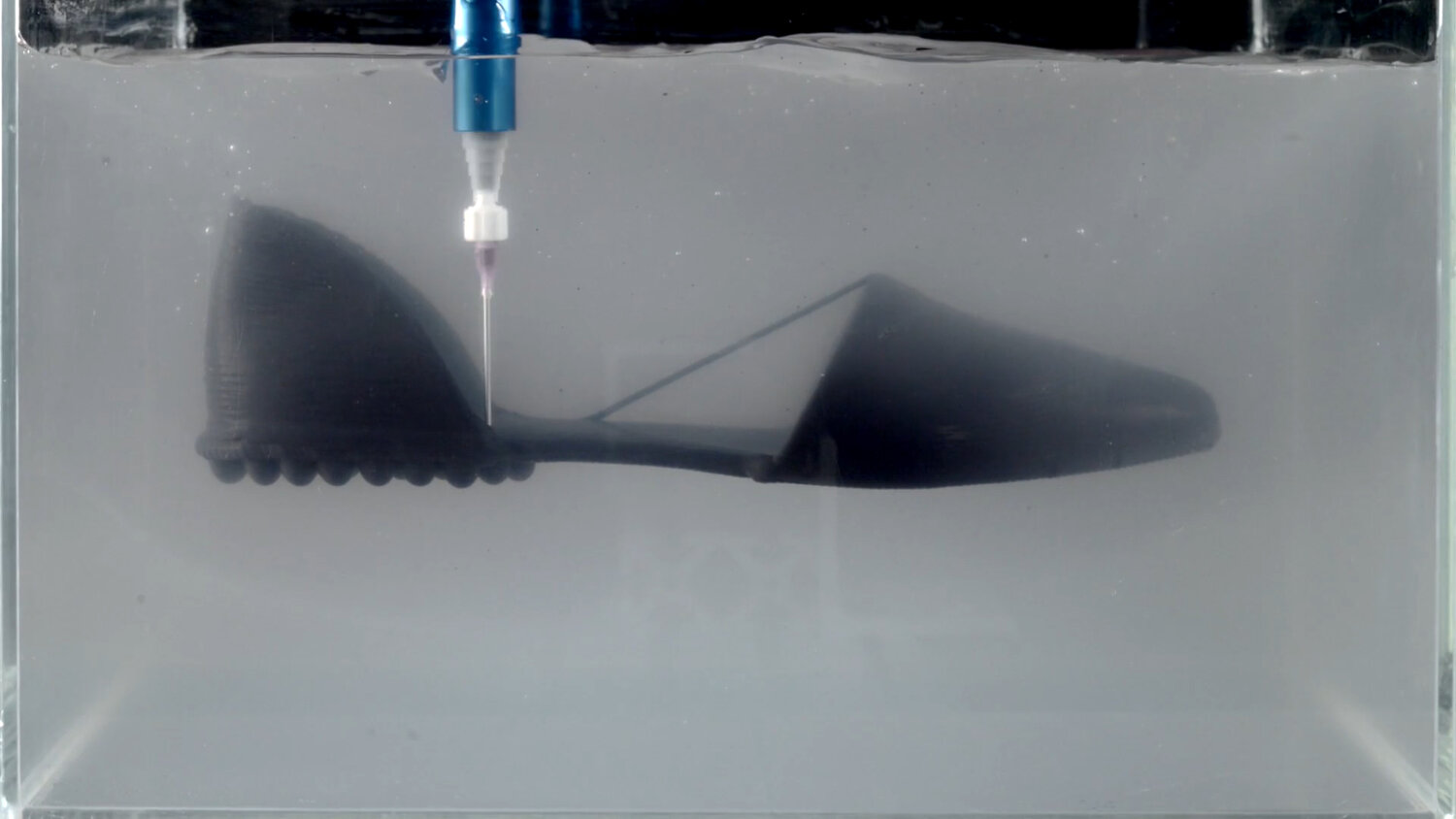

After designing the shoes on a computer, the team 3D printed them into a container of reusable, water-based gel formula. They are printed in liquid rubber using a patented 3D Printing technique. The technique would certainly make you think at the rapid liquid printing technique developed by MIT.

“The typical kinds of 3D printing that exist now require some kind of support material to provide structure for areas of the design that have overhang that would otherwise collapse,” Claypool explains.

In this specific case, the team explained that the shoes can be made from 50% recycled EVA – a percentage that is not possible to reach with injection moulding techniques-. This process might be longer but the company believes the “speed-to-market” is definitely faster than for its injection-moulded shoes.

Footwear companies are increasingly leveraging 3D Printing for its ability to customize and produce when there is a specific demand. Native Shoes aims to let people 3D scans their feet, either in stores or through an application. Thereafter, the data points sent by the customer will be used into the liquid printing program.

Again, a similar technique of 3D scanning has already been used by more than one in the industry: HP, Brooks Running Company, eSun and Cambridge Design Partnership and ECCO – with good reason as it makes no doubt that such type of on-demand ordering would reduce the supply chain and allow any company to reduce excess product sitting in warehouses.

For now, Native Shoes 3D printed footwear would still be in the internal testing phase, so no release date has yet been announced.

Remember, you can post free of charge job opportunities in the AM Industry on 3D ADEPT Media or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com. Happy New Year!