Cambridge Design Partnership (CDP), technology and product design firm, has collaborated with shoe brand ECCO on the QUANT-U (‘quantified you’) project.

The collaboration opens the door to the possibilities of 3D printed footwear for the mass market.

Just as for HP Fitstation, consumers will get a full digital analysis of their foot structure and the way they move in just a few minutes – and shoes will be tailored to their specific requirements in just a few hours.

If you follow 3D printing news for a while, you may have realized, both companies follow the steps of other companies such as Adidas, Feetz, Under Armour or even Brook Running Company that already introduced on the market custom-made footwear using 3D technologies.

The QUANT-U (‘quantified you’) project

In order to quantify the exact measurements of a foot, experts will collect data using gyroscopes, pressure sensors and accelerometers. They will also take into consideration temperature and humidity inside each shoe to create a unique digital footprint.

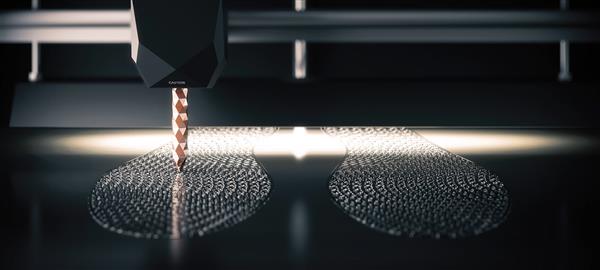

Furthermore, data collected will be translated into geometries for in-store 3D printing of shoes based on each individual’s biomechanical and orthotic parameters.

“The biggest challenge was the fact that the sensors are very close to the ground, hidden inside shoes and covered by a human body – yet they need to send data from both shoes simultaneously to a connected device such as a mobile phone,” said Roberto Basile, a software engineer at CDP. “We needed to maintain reliable communication – using Bluetooth Low Energy – despite the human body acting as an obstacle to the wireless signals. The mechanical system inside the sensor had to be robust enough for people to walk on it, while the battery had to be small and last at least three days without being recharged.”

Both teams achieved the first prototype of the wearable sensor in less than four months. The inbuilt algorithm filters the raw biomechanical data from the sensor into functional information. This data creates the input parameters for a 3D-printed customised midsole for individual customers in approximately two hours. For the QUANT-U pilot, the customised midsole will be paired with ECCO’s iconic Flexure shoe.

The first public release is expected in April at W-21 Amsterdam – ECCO’s concept shoe store. Further info will be provided regarding the exact date.

For further information, follow us on our social media and subscribe to our newsletter!

Would you like to be featured in the next issue of our digital magazine? Send us an email at contact@3dadept.com

//pagead2.googlesyndication.com/pagead/js/adsbygoogle.js

(adsbygoogle = window.adsbygoogle || []).push({});