BLT launches powders for Additive Manufacturing, shares specific cases to highlight their capabilities

To provide more solutions to industrial companies, Bright Laser Technologies (BLT) has introduced a high-strength aluminum for Selective Laser Melting (SLM) and the BLT-Ti65 powder for Selective Laser Melting (SLM) and Directed Energy Deposition...

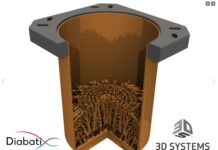

Diabatix and 3D Systems develop an AI-designed 3D printed liquid nitrogen (LN2) heatsink

Diabatix, a software company that specializes in generative AI for thermal management, joined forces with OEM 3D Systems to develop a liquid nitrogen (LN2) heatsink for SkatterBencher and ElmorLabs. While 3D Systems brought its...

Woodside Energy to leverage cold spray 3D printing on offshore gas platform

As part of an oil and gas project, Woodside Energy, a service provider to the oil and gas industry, will rely on a Titomic D523 System to combat corrosion in the Indian Ocean, near...

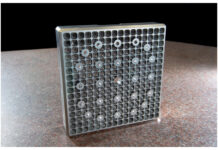

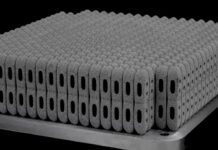

Westinghouse 3D prints bottom nozzles to improve safety and efficiency in operating nuclear reactors

Westinghouse continues its journey in the use of AM within nuclear power plants by releasing recently developed applications. This time, the said application is a set of bottom nozzles designed to improve debris capture...

Aubert & Duval teams up with Alloyed to launch nickel superalloy for Additive Manufacturing

This week at RAPID+TCT 2024, Material producers Alloyed and Aubert & Duval have announced the release of a new nickel superalloy. Named ABD®-1000AM, the material has been developed specifically for AM. This launch marks...

Additive Industries’ latest metal 3D printer comes with adaptable build volume

“The perfect blend of affordability of a small metal printer with the versatility of a larger system”, Additive Industries says.

Dutch metal 3D printer manufacturer Additive Industries unveils this year at RAPID+TCT 2024 a new...

Additive Talks: The use of AM in the nuclear industry and its hidden complexities

This third episode of Additive Talks was the continuation of a conversation that started two years ago during season two of Additive Talks. With different characters this time, this virtual table provides an update...

DMG MORI unveils next-gen LASERTEC quad laser metal 3D printer

Set to make a public debut at RAPID + TCT 2024, OEM DMG MORI recently gave an overview of its latest AM machine at its Open House in Bielefeld. Named LASERTEC 30 SLM 3rd...

Download the May/June 2024 edition of 3D ADEPT Mag

This new edition of 3D ADEPT Mag is a reminder that sometimes, real-life principles can unconsciously be applied to manufacturing concepts. Some people often seek drastic changes or new beginnings, believing that only the...

Phase3D correlates AM build anomalies to part defects for the U.S. Air Force and NASA

Phase3D, an expert in-situ monitoring for additive manufacturing, correlates measurable metal powder bed fusion build anomalies to final part defects in real-time. This work was done for the United States Air Force and NASA,...