I remember the very first interviews I conducted in the AM industry. As a newcomer, I didn’t have enough distance to analyze things. Therefore, I found myself repetitively writing the same sentences, spoken by different people, as if they were the chorus of the same song:

“AM is a sustainable technology by nature.

AM is less expensive than conventional manufacturing technology.

AM can produce parts that were previously impossible to manufacture.

AM can enable decentralized production, thus can be closer to the point of consumption. A shortened and simplified supply chain means a lower environmental impact.”

And just like that, we have started building the “green” credentials of AM. Fast forward to today, I question each of these sentences as we are continuously monitoring data that demonstrate how accurate they are. And then, we came to realize that:

- In a mass production case, the cost of conventional manufacturing remains lower than one-off AM production.

- AM is not necessarily superior to CM processes when it comes to energy consumption.

- When we look at Desktop 3D printers only, users are confronted with the emission of toxic gaseous substances called volatile organic compounds (VOCs) and ultrafine particles (UFP) in the environment.

- Not to mention the fact that, sometimes, supply chains can be complex due to the need for secondary processes and additional supplier requirements.

This list can go on depending on each professional’s experience with the technology. So, should we say that the understanding of sustainability in AM is fairly subjective?

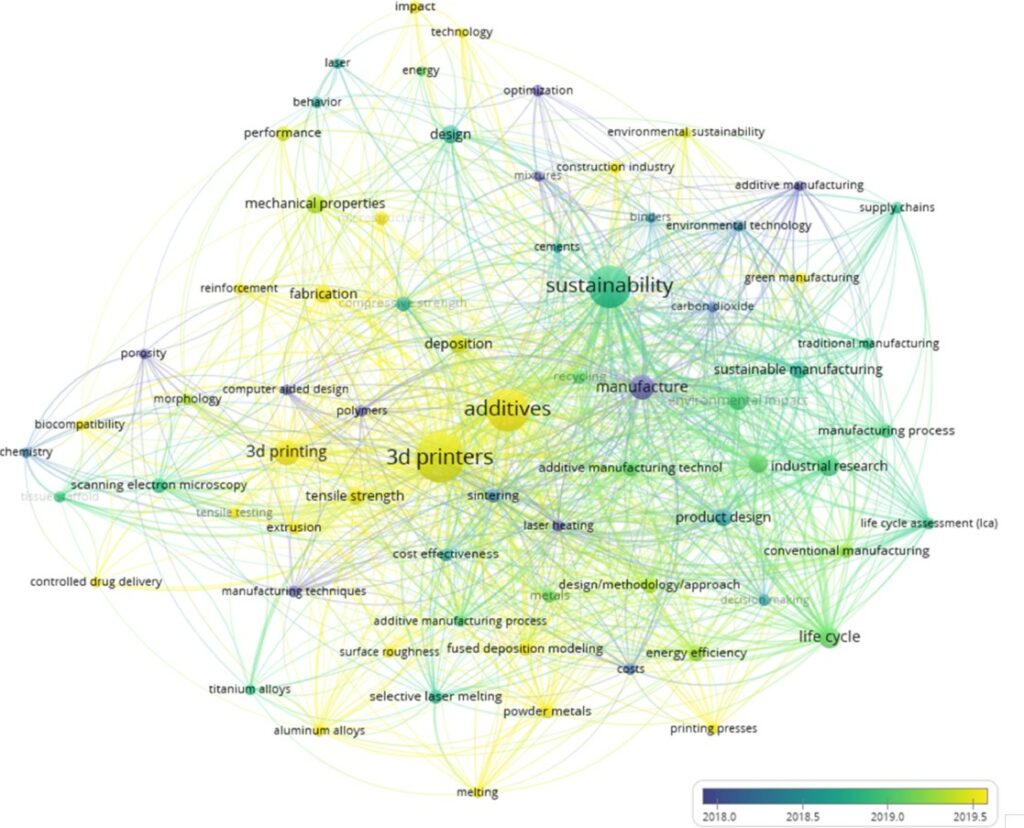

The figure below shows the overlay visualization of keyword co-occurrence which is useful to track the research temporal trends of the analyzed field. Until 2018, research was focused on technological optimization and cost analysis, while in the subsequent year it evolved towards the environmental sustainability topic and the innovative process techniques and tools to be potentially used in additive manufacturing.

For Sarah Jordan, CEO of Skuld, “It is not that it is subjective. It is that it highly depends on one’s assumptions which may or may not be stated. The devil is in the details as there isn’t just one AM and one conventional process. AM for metal is 25+ processes, and at least that many for polymers and even more for composites or ceramics. Conventional manufacturing is several hundreds of processes and a combination of processes. So, it highly depends on what you are comparing. What material, what process, what transportation, what energy source for the process and transportation is used, how much recycling/reuse in the process all need decided both for the baseline and for the AM option. There is also the risk of greenwashing because one can intentionally make assumptions that benefit AM but harm conventional manufacturing.”

As a metallurgical engineer, she brings a pretty metal-centric input to the table. With over 25 years of experience in conventional metals manufacturing, about 8 years in AM, and after getting her MBA, Jordan has cumulated a decade of experience in forecasting/supply chain/operational excellence. She is currently in the University of Tennessee’s Spark Cleantech Accelerator and works as the founder and CEO of Skuld, where they are merging casting process (lost foam) with AM by replacing the petroleum-based foam with a biopolymer.

I love Jordan’s insights here as she has a very critical thinking mindset and as a metallurgical engineer with experience in AM, she brings that technical expertise of both worlds that is very much needed for this topic. But it is not enough.

It was crucial for us to bring the view of a company that believes in a data-driven, multidisciplinary approach to sustainability and energy management. I found that expertise in Foresight Management. Mike Troupos, Vice President at Foresight Management and his brilliant team of subject matter experts confirm some of our assumptions and pinpoints where the struggle is:

“Sustainability in AM is absolutely subjective. In fact, sustainability across the board struggles with subjectivity. A prime example in the AM industry is recycled content and chemical transparency, both high values in the marketplace. However, these items are opposing. The more recycled content used in a product, the less chemical transparency. This is especially true if you are sourcing post-consumer recycled content. The most significant sustainability advantage of AM is that you have significantly reduced “waste” compared to traditional stamping/CNC manufacturing of metals – adding will inherently be less resource/waste-intensive than subtracting. Economies of scale for AM are generally the biggest drawback. It is simply longer and more expensive to manufacture using AM in most cases, especially at large scale.”

The team at Foresight Management champions energy management, accelerates sustainability and increases profitability by working with manufacturers and consumer brands that pursue sustainability and energy management initiatives. If you are a regular reader of 3D ADEPT Media, you may have read one of the studies they conducted last year for the AM division of material producer 6K .

Where are we today?

I can feel the willingness of AM companies that want to explore energy management initiatives, to do better to deliver a product that can legitimately be qualified as sustainable. I see the efforts of organizations like AMGTA that should not be overlooked and in the midst of these efforts, I see a strong reliance on life cycle analysis/life cycle assessments.

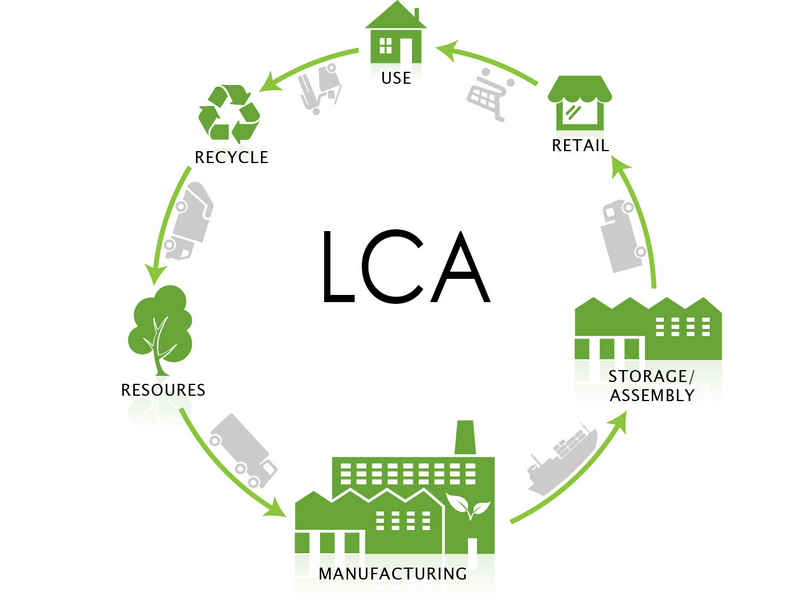

If you’re new to this area, keep in mind that Life Cycle Assessment (LCA) is a tool that helps to assess potential environmental impacts throughout a product’s life cycle, i.e., from natural resource acquisition, via production and use stage to waste management (including disposal and recycling).

If you’re new to this area, keep in mind that Life Cycle Assessment (LCA) is a tool that helps to assess potential environmental impacts throughout a product’s life cycle, i.e., from natural resource acquisition, via production and use stage to waste management (including disposal and recycling).

To date, it’s the only assessment method we have seen AM companies use – which is not bad. The problem is sometimes; we question their accuracy for certain technologies. Remember the conversation Jordan started here. Do LCAs always help to identify the most extensive variables to compare or maybe the question to ask yourself is – what question are you trying to respond to with an LCA?

“LCAs are not all equal.” one learns from Foresight Management. “Each LCA is built to answer a specific question. An LCA done for a printable powder might help quantify the environmental impact of mining and extraction of materials to make the powder, but not address the impact that product has in replacing other materials downstream. A different LCA for the same printable powder could answer the question of how that powder replaces other products in a specific use phase but leave out other uses.

An LCA can account for the entire product lifecycle, including raw material extraction, transportation (upstream and downstream), manufacturing, product use, and end-of-life. The LCA, practitioner, the product designer, and any industry standards dictate which aspects of the product lifecycle are included in the LCA. Additionally, LCAs don’t only quantify GHG intensity (generally, a product carbon footprint, or PCF, is acceptable if you only want to quantify carbon) but also account for water, waste, and other environmental impacts.”

That’s exactly what Jordan decries here: the fact that even though LCA makes sense, most people do not do a full cradle-to-grave assessment and consider all options. Then, it becomes easy to fall into the trap of blanket statements like “metal 3D printing is greener than casting.”

“Are they assuming sand casting? How much machining are they assuming? Since I work in lost foam* I am highly skeptical of any claim of metal AM being green compared to casting when the powder or wire feedstock is required to be melted twice. Once to make the feedstock and once later to make the AM part. Whereas casting is typically taking scrap and melting the material once. I am also skeptical because the vast majority of metal AM parts I see can be cast. Maybe 10% of them are designed such that they must be produced with AM.

*One of the key areas of conventional manufacturing that I am very experienced in is lost foam casting, a type of investment casting that eliminates 95% of the process steps of conventional lost wax investment casting. According to Department of Energy data, lost foam uses 27% less energy, 8% less particulate air emissions, 37% less greenhouse gas emissions, 7% less raw materials, has minimal solid waste. I actually think this data is understated because it has not been updated for process improvements in the past 15-20 years and we know that our yields are typically double conventional sand casting after accounting for the machining losses,” Jordan adds.

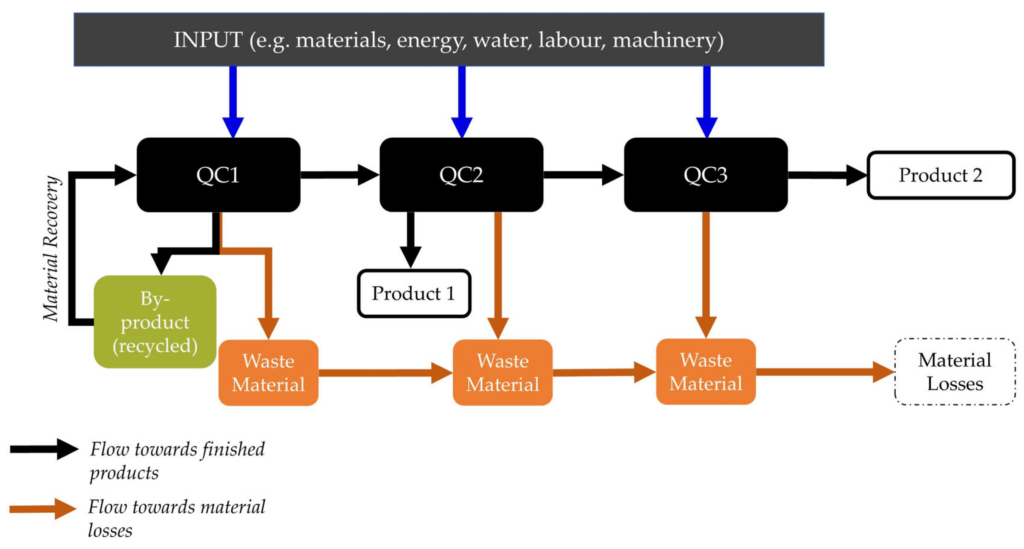

That being said, other assessment methods exist. Apart from LCAs, it’s possible to explore Material Flow Cost Accounting (MFCA). This environmental management accounting method allocates costs to material and energy flows through a process, thereby enabling a simultaneous reduction in environmental impacts alongside an improvement in business and economic efficiency.

Image: Simplified material flow model for a process with three quantity centres (QC1, QC2 and QC3), one byproduct and two products (Source: Adapted from DIN ISO 14051).

Image: Simplified material flow model for a process with three quantity centres (QC1, QC2 and QC3), one byproduct and two products (Source: Adapted from DIN ISO 14051).

Understanding how this can precisely be applied to AM technologies should constitute the subject of another article.

In the meantime, the subject matter experts from Foresight Management remind us that while the LCA modeling framework is the gold standard, it can only be as good as the data entered into the model. The most effective way to improve the accuracy of an LCA is to collect more primary data. Often, a product is modeled with inputs from databases that use industry averages because primary data is lacking. All site/material-specific primary data that is collected makes the findings of the LCA more accurate. This process involves working with your supply chain partners to source their specific data.

On a personal note, in my previous life, I have seen a few trade associations use LCAs as a tool to help their members quantify environmental benefits and improve their designs. Therefore, I do understand that it’s not possible for every company to invest in their own LCA models – and this might become another barrier to taking the leap on their sustainability journey.

Concluding thoughts

I will be cautious with my words while trying to answer the question we asked in the title: “Can Additive Manufacturing (AM) deliver “faulty” implications for its “green” credentials?”

After these insights, I can say that AM does not deliver faulty implications for its green credentials but AM companies might, by highlighting the sustainability of their technology in a wrong way. From a strict adoption point of view, we will agree with Jordan when she says “costs, lead time, engineering design capabilities, and supply chain benefits are way more important to most decision makers.”

However, for those who would like to become more responsible companies, it’s important to keep in mind that the digital transformation of AM comes along with other digitized processes including design, manufacturing logistics and management. According to research, to handle, manage, and extract knowledge from such big data for sustainability considerations, the current manufacturing framework must incorporate a database infrastructure.

This dossier has first been published in the September/October edition of 3D ADEPT Mag.

Read: AM Companies must get started on their ESG journey. Here is how. (Part 1)

Key areas of focus in the application of ESG by AM companies (Part 2)

Editor’s notes

Skuld is on a mission to get metal parts made in the most environmentally friendly and efficient manner which saves time, money, and the planet. The company’s solution includes small-volume custom parts such as for prototypes, rapid emergency replacements, tooling all the way through developing high-volume automotive processes and the equipment to execute processes based on lost foam investment casting and additive manufacturing evaporative casting. The company has a Solar Impulse Foundation certification for its lightweight thin-walled ductile iron solution; the environmental aspect is seen by most as a bonus but not a key factor to adoption.

Foresight’s job isn’t only to perform an LCA, but to help companies holistically understand how to navigate sustainability across their organizations, buildings, and products at the same time. The main value the company has been pushing is transparency as it allows to improve accuracy and accountability. Foresight also helps industry associations create industry-wide models for their members and create Product Category Rules (PCR) for the industry. Having a PCR ensures there is a standardized approach and provides clarity on assumptions for all products in a given industry. Having industry PCRs increases the data quality across the board and lowers the bar of entry for those pursuing LCAs. The company believes that sustainability can mean increased profitability if you get ahead of the curve.