A few days ago, we re-shared an exclusive dossier that highlights how AM companies help to tackle climate change. The dossier recalls the fact that one of the most used tool/model for providing key data is life cycle assessments (LCA) or life cycle inventory analysis, a method that covers 5 major life cycle stages including material extraction, manufacturing, transportation, use, and end of life.

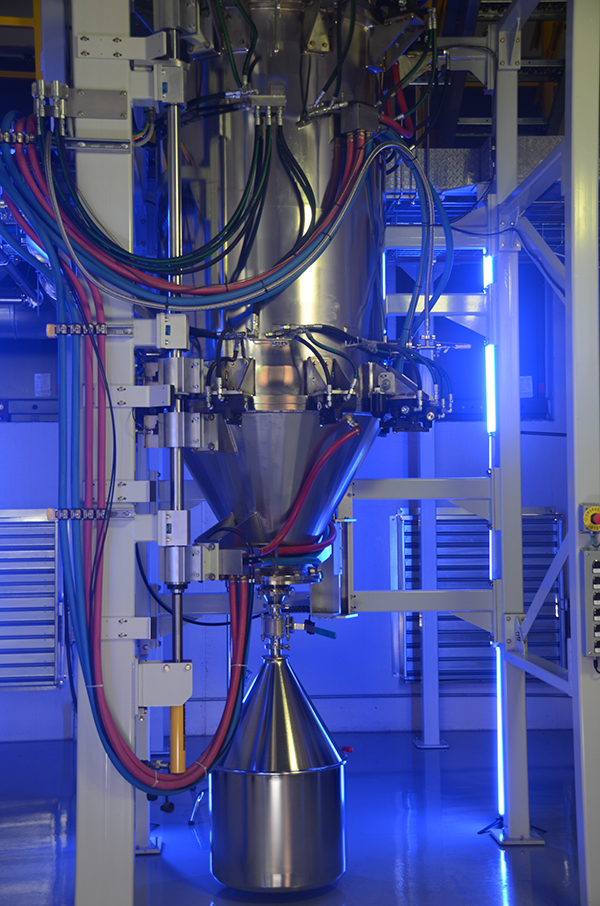

Amid the stakeholders that had been invited to share key insights into how they address this topic, 6K Additive, a division of 6K, a producer of sustainable advanced materials for additive manufacturing and energy storage, highlighted the relevance of the Life Cycle Assessment it was conducting for its AM powder process. The graphs shared at the time enabled to perceive the energy comparison in terms of input materials, gas and power usage, post-processing and totals. In other terms, it is a comparison of the quantifiable environmental impacts between traditional metal powder production methods and 6K Additive’s proprietary UniMelt® process.

The company shared more information about this life cycle assessment yesterday. Conducted by independent consultancy firm, Foresight Management, this LCA is said to be the first one conducted for additive manufacturing powder process.

The results show the UniMelt process significantly reduces environmental impact in the key areas of energy usage and global warming, potentially helping 6K Additive customers lower their carbon footprint using metal additive manufacturing, 6K announced.

Frank Roberts, 6K Additive president, said: “This assessment goes a long way in revealing how the UniMelt process exceeds traditional metal powder processing in environmentally important ways, while also pointing to the inefficiencies of atomization that currently plague AM material production. Sustainability is at the core of who we are at 6K Additive and providing our customers with quantifiable numbers related to the environment helps them move closer to zero carbon manufacturing with AM.”

Founded in 2007 as a boutique performance contractor named Midwest Energy Group, Foresight Management has been helping companies understand the impact their processes have on a global environmental scale through LCA. Their methodology includes primary and secondary data, as well as using GaBi software to provide data detailing environmental impact of sourcing, refining, and processing.

“This is a cradle-to-end user assessment of the UniMelt technology. We studied all known industrial processes from raw material acquisition and processing up through manufacturing and customer distribution,” explained Brad Van Valkenburg, sustainability manager at Foresight. “This assessment focused on nickel and titanium powders, both of which saw significant advantages when made using UniMelt process. The nickel results showed the UniMelt required 91% less energy and reduced carbon emissions by 92% and the titanium results showed the UniMelt required at minimum, 74% less energy and reduced carbon emissions by 78%.”

It’s a bit of a shame that we did not receive further data regarding this LCA but at a time when organizations increasingly look for suppliers who can provide statistics that help them with their sustainability journey, 6K Additive is making a first tangible step that backs up sustainability claims and that’s something, I can only encourage.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com