The first part of this dossier shed light on the importance of implementing an ESG strategy taking into account the legislation that applies to your specific situation. While each company’s sustainability journey is unique and may vary depending on its location(s), value chain, investors, or partners, there are a couple of pain points that all AM companies can relate to. This article aims to highlight them. It will also shed light on a few companies that have already taken the leap on ESG.

As a reminder, Environmental, Social and Governance (ESG) is a framework used to assess an organization’s business practices and performance on various sustainability and ethical issues. The AM industry focuses a lot on the “E” part of this acronym. As per the words of Simon Schlagintweit, Medical Expert & Lead Auditor Additive Manufacturing at TÜV SÜD, the biggest impact when it comes to the environment is “the feedstock– how sustainable is the feedstock, how effective is the recycling and waste management – and energy consumption of the various machines required.”

Long story short, TÜV SÜD goes in different directions to support and enhance the ESG internationally. A few examples are their core business of testing, inspection, and certification, which cover all ESG topics from product and employee safety to regulatory compliance. More in-depth examples of their services are climate neutrality services or industrial cyber security.

In the AM industry, a few software providers like CASTOR and Siemens have developed a CO2 Emission Calculator tool that would help manufacturers reduce their CO2 emissions. The calculation behind the CO2 analysis of CASTOR, for instance, takes into account various parameters along the full lifecycle of the product.

While there is a great chance that many parts won’t be able to be taken into account in this newly created process, the importance of CO2 measurement might create a paradigm shift for those industrials starting their AM journey as there would be a great temptation to produce AM parts that will be directly optimized for CO2 reduction. Moving forward, given the climate emergency, others will have no choice but to follow the move.

However, as you will see in PART 3 of this dossier, much more can be done to reduce the risks of AM activities at the environmental level.

The “S” of ESG for AM companies

The “social” or “S” elements of ESG played for a long time a secondary role to environmental and governance factors. This can be understood by the fact that environmental and governance issues are much more clearly defined.

In the AM industry, the main issue around the “S” of ESG is for Schlagintweit, the workforce. “On the one hand, safety is important for the workforce, as AM can be dangerous in some circumstances. On the other hand, training and specialization are necessary. Comprehensive training is not yet fully available (e.g. apprenticeships or academic courses). In addition, supply chain responsibility naturally affects the AM industry, e.g. where the raw materials and/or products come from and how they were produced,” he adds. For the expert, education and general product safety are especially pivotal when AM is leveraged in highly critical sectors like automotive, medical, and aerospace.

In a tech industry like AM, I believe the rationale behind the “S” element can go further to lay emphasis on questions of diversity, equity, and inclusion (DEI). If we look at the theory only, the first hurdle we will see is the lack of data that explains the current situation of each organization.

The other hurdle is time and resources. As a lead author of a previous Women in 3D Printing “Diversity for AM Report”, I came to realize that going beyond a marketing promise or a marketing action that consists in highlighting a person from a minority ethnic group on one’s website, requires time and money. Time to educate one’s employees on these questions and money to invest in services that will help you deploy tangible actions across all departments. It should be a joint work between Marketing, HR and Management teams.

The “G” of ESG for AM companies

At this level, AM companies should focus on transparency in the supply chain and throughout the company.

For TÜV SÜD’s representative, AM companies should provide clear answers on “where does everything come from and where does it go (again, supply chain responsibility)? What is being produced (e.g. counterfeit products or medical devices)? Are all necessary and relevant regulations and standards being adhered to?”

According to this expert, the governance issues affecting the AM industry are related to intellectual property rights and data security – what is printed, is it the original data and how can we make sure it is not stolen –, quality assurance – even though specialized QM AM standards are being published (like ISO/ASTM 52920) the industry needs to adopt them as well.

Overall, it is important to keep in mind that corporate governance is the set of rules, practices, and processes that determine how a company is operated and controlled. Its main aim is to ensure that the company acts in an open and accountable manner and that its leadership acts in the best interests of stakeholders.

ESG programs?

It is too soon for us to legitimately say or recommend that a specific ESG program has already borne fruit within a specific AM company. Especially taking into account that “the landscape of regulation and policies change regularly as new regulations and standards are being developed.” As Schlagintweit points out, these influences “the AM industry, from product regulation (e.g. MDR), Data and cyber security (e.g. CRA) to supply chain regulations (e.g. European Supply Chain Act). Additionally, new standards are being developed and published on topics like EH&S, QM, or material specifications, which can support and influence how regulations need to be addressed.”

As such, ensuring the maturity of ESG programs requires “independent (3rd party) reviews, assessments and audits of supply chains and companies, to make sure these adhere to set policies & regulations and to have these kind of assessments and audits, clear metrics and requirements need to be defined. When we have metrics and requirements and thus more data, these can be used to analyze and interpret via AI or big data to identify issues or future trends. Moreover, these data can be used for monitoring & reporting, benchmarking, improvement loops and transparency,” Schlagintweit concludes.

That being said, one should recognize the efforts of AM companies that have taken the leap on ESG. Stratasys is an example that is worth mentioning here as not only are they attempting to track and limit their footprint, but they also introduced renewable energy through solar panels at some factories and have dozens of additional initiatives to address waste streams and optimize operations. These initiatives are highlighted in their first ESG report published last year.

Another company that we should observe in this field is Prusa Research. Founded in 2012, the founder Josef Prusa and his team were able to manufacture 101 232 3D printers in 2022, delivered across 149 countries (data of 2022 shared by the company). The company started focusing on sustainability at the end of summer 2021 – being aware of the environment in which they make business, and more importantly, of the CSRD Directive that will require companies to publish their ESG report from 2025 onwards. (See more information in PART 1 of this dossier).

“We have drafted our sustainability strategy, together with our main stakeholders (employees, suppliers, academy / NGOs and 3D printing community). In June, this year we launched our first ESG report to show where we are and what we aim for,” Vladimír Víšek, Sustainability Manager told 3D ADEPT Media.

More specifically, what have they done so far?

First, Prusa Research identified the three cornerstones of its strategy as followed: environment, 3D printing for a better world and fair relations.

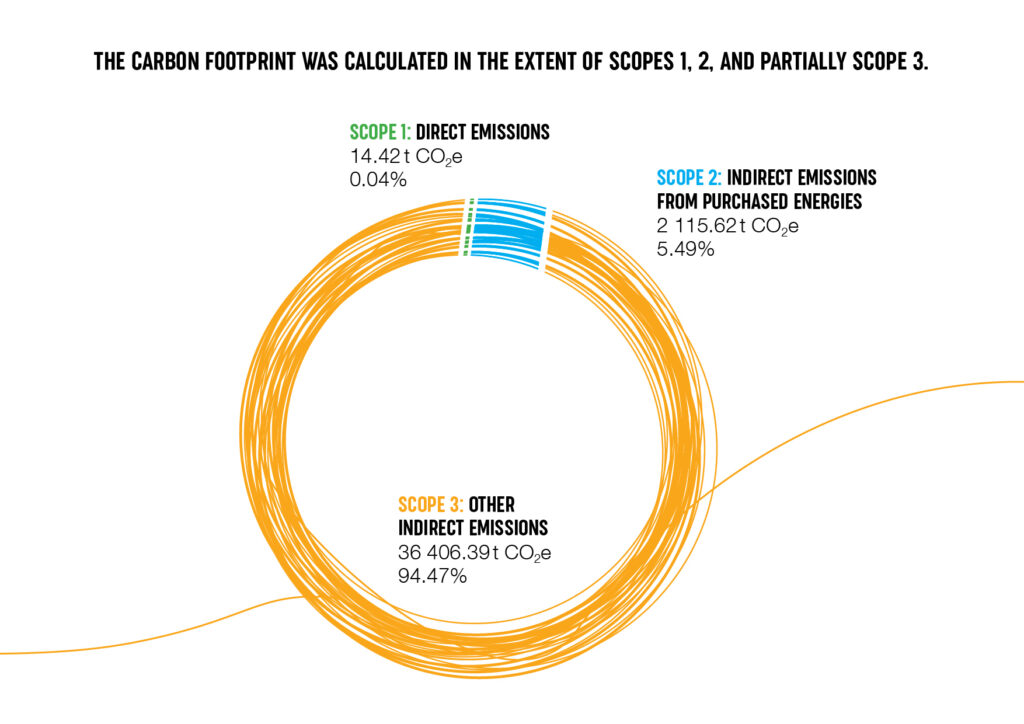

At the environmental level, they calculated their carbon footprint taking into account direct emissions (scope 1), indirect emissions from purchased energies (scope 2), and partially indirect emissions (scope 3). In Prusa Research’s case, direct emissions include fuel for company cars and refrigerants for air conditioners. Indirect emissions from purchase energies refer to electricity and direct heating supply. Other indirect emissions include purchased supplies and their transportation to Prusa Research, transportation of finished products from Prusa Research to customers, investments into Prusa Research tangible assets, business trips, commuting, or home office – and on top of that, water consumption and waste management. The company also acknowledges that so far, they do not have reasonable data to calculate CO2 emissions of 3D printers operated by their customers and to take into account the end of life of their printer– which is fair enough, right?

“Frankly, it was a lot of work – considering and accurately identifying all the materials we use in our production, contacting suppliers and finding out from where and how a given component is delivered to us, keeping track of the energy and water consumption, or making a survey on how our colleagues travel to work,” the company says in its report. The carbon footprint was calculated by CI3 company and independently verified by Envitrail company. The calculation is made according to the international GHG protocol and ISO 14064-1.

Prusa Research has also introduced a digital product passport – as a way to strengthen their sustainability efforts by designing and manufacturing 3D printers that meet the requirements of the circular economy. To date, the Prusa Product Passport includes the origin of the 3D printer, the carbon footprint of the 3D printer, information on maintenance, repairability, and spare parts, information on upgrades, description of the materials of each part for the purpose of recycling as well as inspiration on how to reuse selected printer parts at the end of their lifespan.

As said before, the social part of ESG can be interpreted in several ways. One of the actions we will keep from Prusa Research is their Prusa Education (Průša pro školy) program designed for all schools, universities, and other educational institutions in the Czech Republic. Launched in September 2020, the program aims to develop 3D printing-related skills in a fun way.

“We donate a free printer to each school that publishes an educational project on 3D printing. These projects are then available free of charge to all other schools. So far we have donated 1,369 printers,” the report reads.

As for the G of ESG, the company describes in its report the advantages they provide their employees with to ensure an ideal work-life balance as well as measures they take to ensure a worker safety system above legal standards.

Prusa Research still has a long road ahead. As a matter of fact, their report clearly outlines what are their next plans. And that’s something we are willing to follow to share examples of what can be done in the AM industry.