Impossible Objects releases new Composite 3D Printing System and partners with BASF

We haven’t heard much about Impossible Objects in 2 years. Following the launch of their first Composite-based additive manufacturing system in 2017, the company’s system has been coveted by a certain number of Fortune 500 companies.

Today, the company announces two watershed advances in composite 3D printing and a partnership with BASF. The agreement with BASF will consist in taking advantage of PA6-carbon fiber composites to extend Impossible Objects’ patented composite based additive manufacturing process (CBAM).

The CBAM-2 combines high-performance polymers with long-fiber carbon and fiberglass sheets to rapidly produce 3D composite parts that are stronger, lighter, with better temperature performance, and more durable than possible with conventional 3D printing methods.

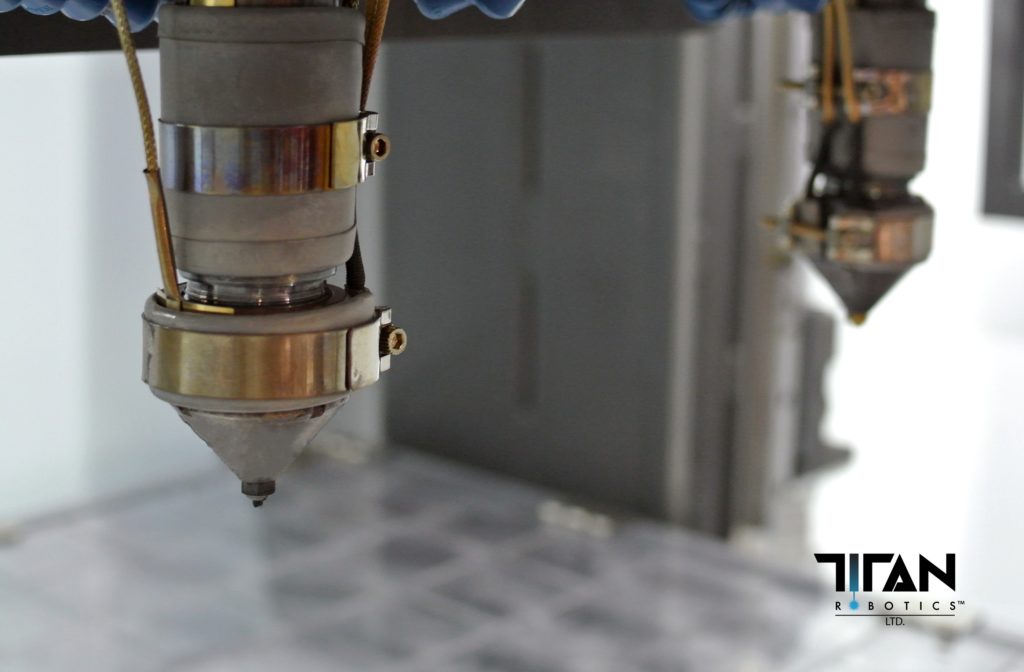

Titan debuts new 3D printer with dual pellet extruders

Titan Robotics, Ltd. Is one of the pioneers in the development and implementation of pellet extrusion technology. The manufacturer has launched a 3D printer with Dual Pellet Extruders at the Rapid+TCT event.

The new Atlas-H product line features dual retracting pellet extruders combined with a robust frame and industrial closed-loop motion control system that enable print speeds reaching 30,000mm/minute. The Dual Pellet Extrusion System further reduces part production costs by combining high-speed printing with the ability to use a wider range of low-cost pellet feedstocks. This provides additional production solutions that enable the adoption of polymer extrusion 3D printing on the factory floor.

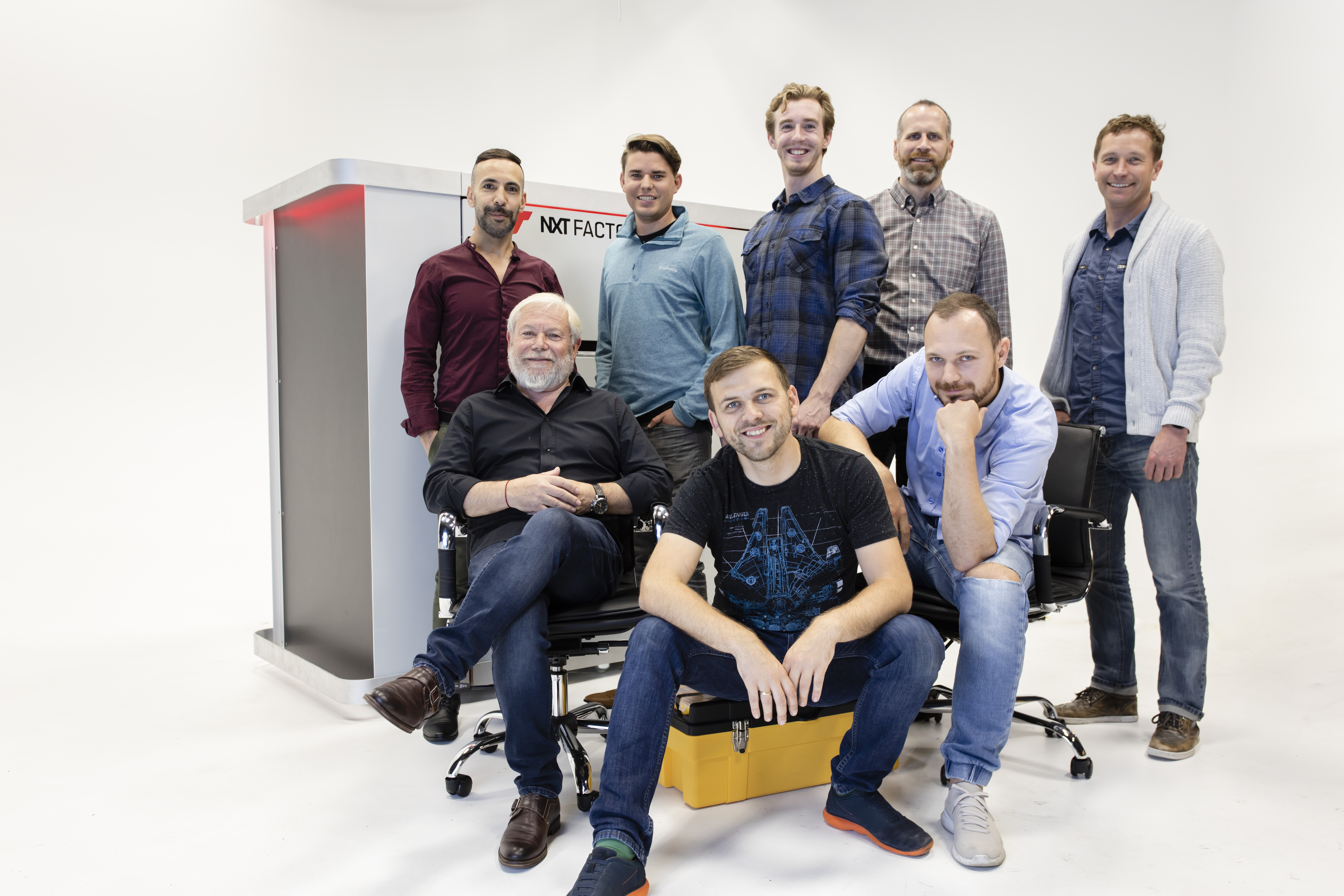

NXT Factory launches Quantum-Laster Sintering 350 System

While its sister company, Nexa 3D announces immediate availability of NXE400 3D Printer, unveiled at Formnext 2018 and at CES 2019, NXT Factory launches a 3D printer that additively manufactures thermoplastics. Named QLS 350, the polyamide manufacturing system is said to deliver significant savings compared to traditional tooling costs and provides unprecedented production throughput and flexibility.

It integrates a removable robotically guided print chamber, for independent cool down and

autonomous depowering module, and, according to the company, it produces up to 4X the print speed of traditional laser sintering technologies.

You can now post free of charge job opportunities in the AM Industry on 3D ADEPT Media.

For further information about 3D Printing, follow us on our social networks and subscribe to our newsletter!

Would you like to be featured in the next issue of our digital magazine? Send us an email at contact@3dadept.com

//pagead2.googlesyndication.com/pagead/js/adsbygoogle.js (adsbygoogle = window.adsbygoogle || []).push({});