Mimaki is a Japanese company that has built a whole universe around digital printing. Founded in 1975, the company manufactures wide format inkjet printers and cutting machines for the sign/graphics, textile and apparel, and industrial markets.

After 45 years in the 2D Printing market, the company has started to develop a new strategy towards the 3D printing market. With the same focus on colour, the manufacturer has put tremendous efforts to ensure a true heritage of innovation.

To understand the reasons that explains this move and to discover the specifications of their flagship product in the 3D Printing industry, Jordi Drieman, the 3D specialist of the company answered our questions for this Opinion of the Week.

With an engineering background, Jordi Drieman has been dealing with 3D technologies since the early stages of the RepRap project. Like real enthusiasts, he has built some FDM 3D printers and learned about the entire 3D workflow process, from software to post processing.

Leveraging 2D Printing skills to enter the 3D Printing industry is quite unusual; how do you explain this move? And how do you perceive the response of 3D Printing professionals?

Mimaki has been in the 2D printing market for nearly 45 years now, so it is only logical for us to explore the realm of 3D printing. With our heritage and expertise in printing, we are confident that we can offer a 3D printer that delivers high print quality, stable performance and advanced uptime.

We’ve also introduced technologies from 2D inkjet printing to the 3D market. The use of ICC colour profiles, for example, is common in 2D printing but completely new for the 3D industry. It enables our 3D printer to print with exact colour match (WYSIWYG). I’m sure there are a lot more technologies from 2D printing that we can apply to 3D printing as well.

Overall, the response from 3D Printing professionals has been really positive. Many are very impressed with the photorealistic print quality of the printer and how life-like the models look when they are finished. The colour capabilities of the printer stand out within the market which has led to fantastic feedback.

According to you, what are the challenges of digital large-format printing on the current market?

Full colour is relatively new for the 3D market and the challenge for Mimaki is to show why 10 million colours are necessary. To take advantage of the full colour range we also need to provide extensive training across the entire workflow.

A key focus of Mimaki at Formnext 2018 was the 3DUJ-553 3D printer, could you tell us more about the 3D Printer?

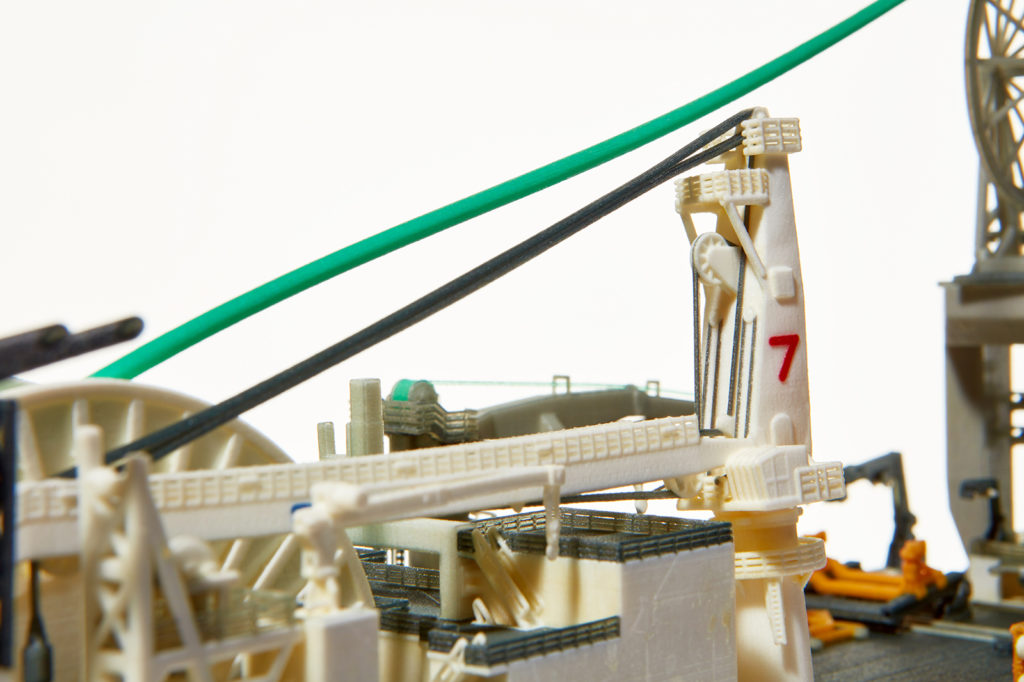

Developed based on our expertise in industrial 2D inkjet printing, the Mimaki 3DUJ-553 is the company’s first 3D printer. It is the first ever polymer 3D printing system that enables more than 10 million different colours. Based on UV-curable inkjet technology, it builds objects by jetting successive layers of inks that are hardened by LED UV light at each pass. Using CMYK, white and clear inks, it produces photorealistic products, with rich colour expression including spot colour, shades, and gradients.

How does your 3D Printer distinguish itself from others of the same range?

Definitely its colour capability. The colour range and vibrancy combined with the ability to match colours with such accuracy open up some very exciting application possibilities. For instance, skin tones – where the slightest variations can easily be detected by the human eye – are reproduced with photorealistic quality as Mimaki technology scans with absolute precision. When you compare our print results with other machines that print up to, let’s say, 1 million colours, you will see the difference in quality. Furthermore, with our unique use of ICC colour profiling, the results are consistent—you will always get the same quality, no matter which Mimaki 3DUJ-553 printer you use and at which production site the machine is located.

Our support material is also unique. It is water-soluble and simply dissolves in water. This means you only need to submerge it in water and there is no water-jetting involved, which may damage delicate parts of the model.

What type of applications can the printer achieve?

The printer is capable of achieving a diverse range of applications, all of which require accurate colour matching. Examples include scaled models, mock-ups and prototyping to 3D art, tools and equipment, figurines, as well as medical and educational applications.

Could you share an exciting challenge you encountered with the 3DUJ-553 3D printer in one of your use cases?

Every week I encounter new & exciting challenges. All the applications or projects we are involved in are quite challenging.

Recently, we printed medical scans of real patients. The results are so realistic that some people find them scary. Doctors have shown a huge interest in the 3D models, as they can use the models to practice and prepare themselves before they perform a surgery. This may be particularly beneficial for undertaking surgeries on infants and patients with rare conditions.

The most challenging aspect of 3D printing is the preparation of the data; every detail must be correct before printing so that the end result is exactly as the customer envisioned.

For further information, follow us on our social media and subscribe to our newsletter!

Would you like to be featured in the next issue of our digital magazine? Send us an email at contact@3dadept.com

//pagead2.googlesyndication.com/pagead/js/adsbygoogle.js

(adsbygoogle = window.adsbygoogle || []).push({});