3D printer manufacturer BCN3D has recently unveiled what it describes as the modernized version of its signature IDEX technology. Named BCN3D Omega I60, the all-in-one industrial FFF 3D Printer, designed to produce tooling, jigs, and fixtures, would double productivity by using both toolheads simultaneously.

With a print volume of 60L and an active heated chamber that can reach temperatures up to 70ºC, the 3D printer could print both strong prototypes and end-use parts. It is equipped with a temperature and humidity-controlled material operations system that prepares filaments for printing. Additionally, it utilizes a 1.75mm direct-drive high-speed extruder capable of speeds up to 300 mm/s.

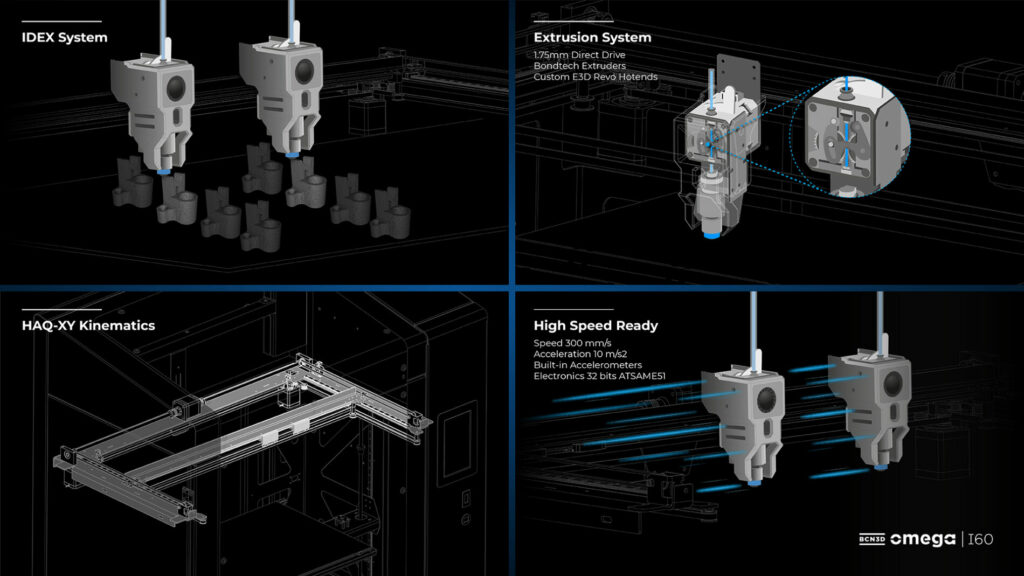

Other key specifications of the 3D printer include the Independent Dual Extrusion (IDEX) technology, HAQ-XY Kinematics, an extrusion system, a Material Operations System (MOS) that enables the control of both humidity and temperature as well as an XYZ Autocalibration.

BCN3D Omega I60 utilizes an improved version of the kinematic system by placing the pulleys in a more optimal position. As a result, the system experiences a significant reduction in torsional moments along the X axis during the printing process. These torsional moments are highly undesirable as they can have detrimental effects on the system’s performance and potentially lead to undesired deformations in the X axis, thereby directly impacting the quality of the printed parts.

BCN3D Omega I60 utilizes an improved version of the kinematic system by placing the pulleys in a more optimal position. As a result, the system experiences a significant reduction in torsional moments along the X axis during the printing process. These torsional moments are highly undesirable as they can have detrimental effects on the system’s performance and potentially lead to undesired deformations in the X axis, thereby directly impacting the quality of the printed parts.

Furthermore, the 3D printer’s extrusion system features 1.75 mm direct drive Bondtech LGX Pro extruders. This system provides more control and precision. It also includes custom E3D Revo hotends, which offer best-in-class extrusion reliability, as well as an easy-swap nozzle change.

Other worth mentioning features include a built-in camera, a flexible build plate, an Uninterruptible power supply (UPS), a Filament Runout Sensor (FRS), a barcode sensor for spool and components recognition, an andon light, a 7” capacitive touchscreen, an HEPA and Carbon filter, a Safety Pause function, an emergency stop button and WiFi or Ethernet connectivity functions.

Other worth mentioning features include a built-in camera, a flexible build plate, an Uninterruptible power supply (UPS), a Filament Runout Sensor (FRS), a barcode sensor for spool and components recognition, an andon light, a 7” capacitive touchscreen, an HEPA and Carbon filter, a Safety Pause function, an emergency stop button and WiFi or Ethernet connectivity functions.

The launch of the Omega 160 coincides with BCN3D’s 11-year anniversary, a journey that saw the delivery of over 10,000 units worldwide across more than 100 points of sales. While those machines were mostly based on the IDEX technology unveiled in 2015, the manufacturer is now looking forward to building a similar – if not bigger momentum – for its VLM™ technology, unveiled last year.

Remember, you can post free of charge job opportunities in the AM Industry on 3D ADEPT Media or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com