Nexxt Spine, an Indiana-based manufacturer of spinal implants is pushing medical innovation forward using additive manufacturing technology. Founded in 2009, it was two years ago that the company began using additive manufacturing. Today, the company installs its fifth Concept Laser Mlab additive manufacturing system.

This investment shows that the medical company sees

potential in additive manufacturing both in terms of production and sales.

“We used the first Mlab primarily for

R&D purposes, but we soon realised that further investment in additive

technology could add value not only to our overall growth strategy, but also at

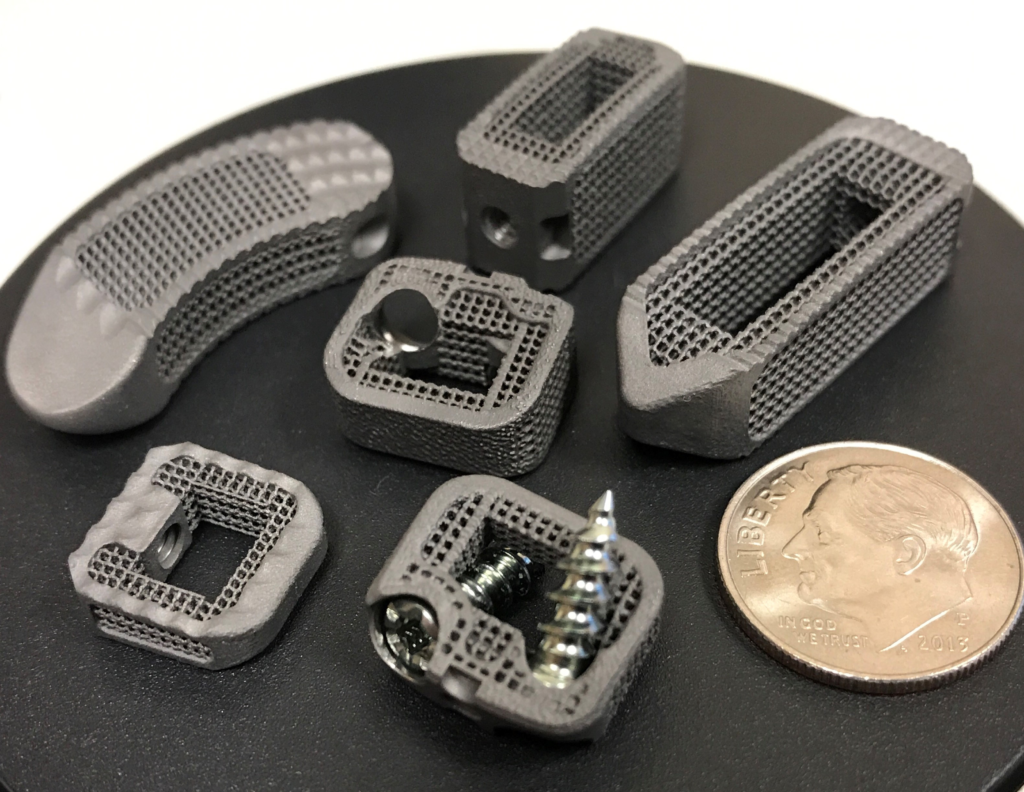

a clinical application level with the ability to develop implants with very

intricate micro-geometries that could maximise healing. Over the past two

years, we have made a seamless jump from R&D to serial production and in

doing so have significantly accelerated the time from concept to

commercialization,” explains Alaedeen

Abu-Mulaweh, director of engineering at Nexxt Spine.

At the production level, using Concept Laser Mlab machines has enabled the manufacturer to take control over the entire design, production and distribution process in-house, while breaking existing barriers in terms of speed of development and commercialization.

The spinal implant market

AM is definitely the trend among tech medical companies that are able to deliver patient-specific solutions. From 3D printed cages platforms to implants, the aim is to be able to ensure durability and improve patient outcomes.

The biggest challenge for medical companies is sometimes to find the technology that best meets their needs. Indeed, given the important investments, and the use of the technology in such vital sector, confidence in a technology is more than crucial.

As far as Nexxt Spine is concerned, the company seems to not have faced such challenge. “Nexxt Spine is another great example that shows the power of our Mlab machine, which is proven to be an easily accessible machine for research & development, with the capability to be a reliable, scalable and modular production machine at the same time,” comments Zeidler, senior global and key accounts director for the medical sector at GE Additive.

For further information about 3D Printing, follow us on our social networks and subscribe to our newsletter!

Would you like to be featured in the next issue of our digital magazine? Send us an email at contact@3dadept.com

//pagead2.googlesyndication.com/pagead/js/adsbygoogle.js (adsbygoogle = window.adsbygoogle || []).push({});