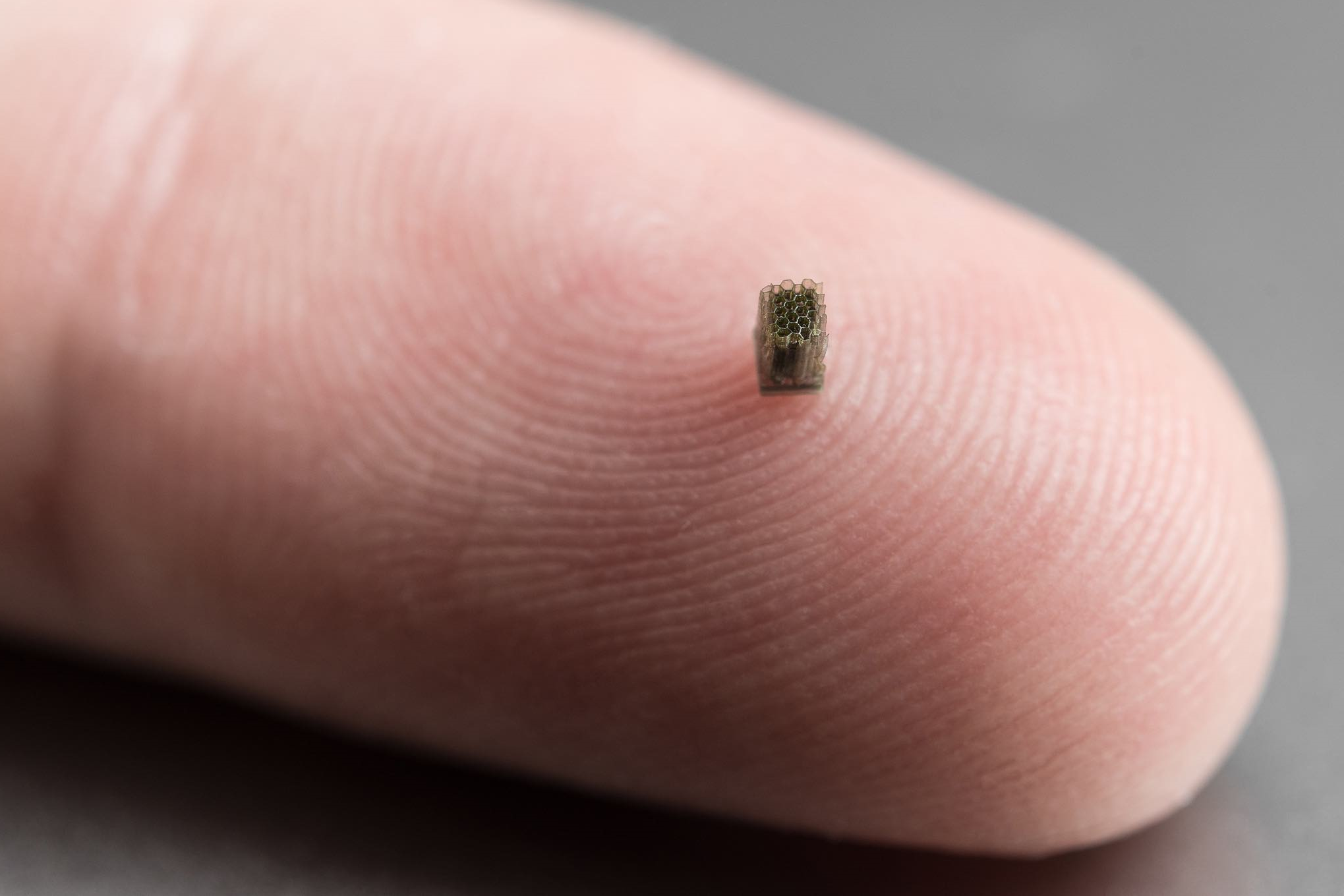

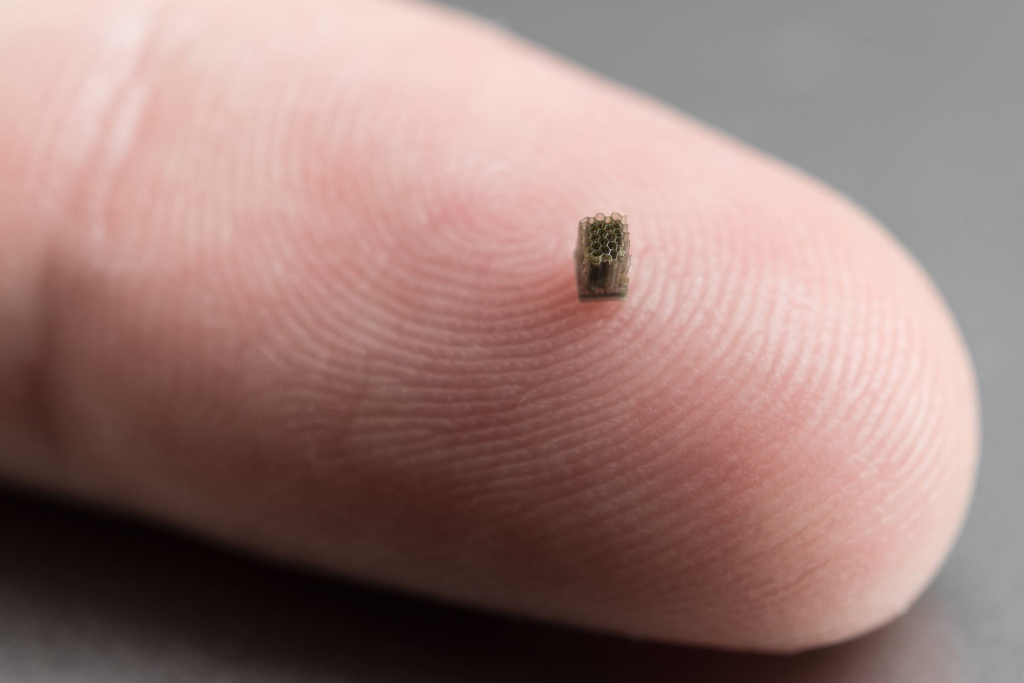

Nanofabrica, a specialist in precision additive manufacturing platforms, announces the commercial availability of its mass additive manufacturing technology.

Nanofabrica’s alternative to what has previously been considered as the standard in micro manufacturing enables significant improvement in product design and development.

Nanofabrica’s alternative to what has previously been considered as the standard in micro manufacturing enables significant improvement in product design and development.

Companies that specialize in the fabrication of micro parts are increasingly exploiting the possibilities that exist in the use of additive manufacturing for the micro manufacturing arena. As Ruth Houbertz said in a recent Opinion of the Week, they “are bridging the gap between micro/nano technology, 3D Printing and injection moulding.” Others such as Nanoscribe are also paving the way to a new approach of micro manufacturing.

What makes Nanofabrica outstanding?

Two words we will keep in mind are agility & flexibility. Other relevant features include the workflow’s optimization and the possibility to achieve high volume applications.

Nanofabrica explains that its technology is much more agile and flexible than current alternative manufacturing technologies. It does not require any specific tooling therefore, designs can be altered with little expense.

Furthermore, with an optimized workflow, the technology produces less scrap and fewer tools than conventional manufacturing processes. It also promotes the reduction of iterative process, assembly, and inventory. This means that significant operational cost benefits are now attainable at the micro manufacturing level.

Lastly, while the Nanofabrica micron-level additive manufacturing process can cater for high volume applications (multiple thousands of small parts and components fitting easily in the machine’s build envelope), the introduction of a 3D printing solution for micro manufacturers also means that OEMs are able to reduce the reliance on economies of scale, as the technology makes full production runs measured in thousands as inexpensive as producing one.

The Nanofabrica technology makes low to medium-volume production runs possible that have previously been uneconomic due to the high tooling and set-up costs associated with traditional manufacturing alternatives.

You can now post free of charge job opportunities in the AM Industry on 3D ADEPT Media.

For further information about 3D Printing, follow us on our social networks and subscribe to our newsletter : Facebook, Twitter, LinkedIn & Instagram !

Would you like to be featured in the next issue of our digital magazine? Send us an email at contact@3dadept.com

https://pagead2.googlesyndication.com/pagead/js/adsbygoogle.js

(adsbygoogle = window.adsbygoogle || []).push({});