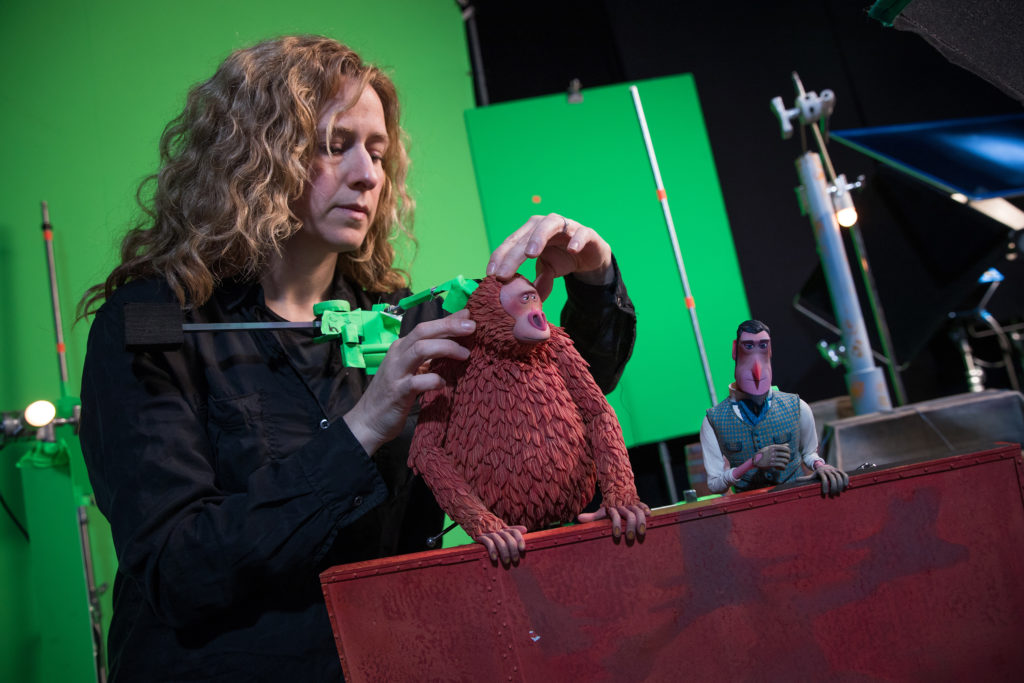

Laika’s recently released film, “Missing Link”, has seems to have required various types of 3D printing technologies during the preparation. The first application of the technology revealed within the movie is Susan, the 3D printed shoe produced by Nike and Stratasys, and inspired by one of the main characters of the movie.

We have recently been informed that Fraunhofer IGD, an institution for applied research in the field of visual computing, has provided its 3D printing technology to produce a myriad of models, including subtle changes in facial expression for each individual character.

According to Fraunhofer IGD, the movie would be the first to make use of their Cuttlefish 3D-printer driver. One of the issues encountered by experts during the manufacturing process was to ensure that the colors of each model seamlessly match the ones used in previous frames.

Laika’s Director of Rapid Prototype, Brian McLean, explains that “Missing Link” was not their first experience in 3D Printing. However, he recognizes that combining two different technologies was a true asset for the production of these models : “[For] “Missing Link,” we leveraged Fraunhofer IGD technologies because they are unrivaled in terms of color consistency and geometric accuracy. The combination of Cuttlefish software and Stratasys J750 hardware has allowed us to produce the most sophisticated colored 3D prints ever.”

A few words on Cuttlefish

Cuttlefish is a voxel-based universal printer driver, meaning it can be deployed for diverse 3D output devices. The driver makes it possible to work simultaneously with multiple printing materials. It also enables high-fidelity reproduction of the shapes, colors and subtle color transitions of the original, and it allows objects to be simulated on-screen prior to printing. In addition, it is now possible to print translucent, i.e. partially to fully transparent, objects.

Beyond the audio-visual industry, the capacities of the software can be exploited in medicine, automotive engineering or cultural heritage to name a few.

For further information about 3D Printing, follow us on our social networks and subscribe to our newsletter!

Would you like to be featured in the next issue of our digital magazine? Send us an email at contact@3dadept.com

//pagead2.googlesyndication.com/pagead/js/adsbygoogle.js (adsbygoogle = window.adsbygoogle || []).push({});