It’s been 4 years that Endurance brings added value to the 3D printing community with its laser attachments. Looking back at what he has built, Endurance’s CEO, George Fomitchev, remembers the challenges he encountered in this adventure, how they allow him to position the company in this community, and how far he still has to go to maintain this positioning.

In this company’s profile, Endurance presents its range of products, what’s in the pipeline (in terms of R&D and collaborations), the applications and the reason why its brand awareness keeps increasing in the community.

A wide range of laser attachments to serve various needs

Endurance has developed several laser add-ons:

- 2.1 watt laser

- 3.5 watt laser

- 5.6 watt laser

- 8 watt laser

- 8.5 watt laser

- 10 watt laser

- 10 watt+ laser

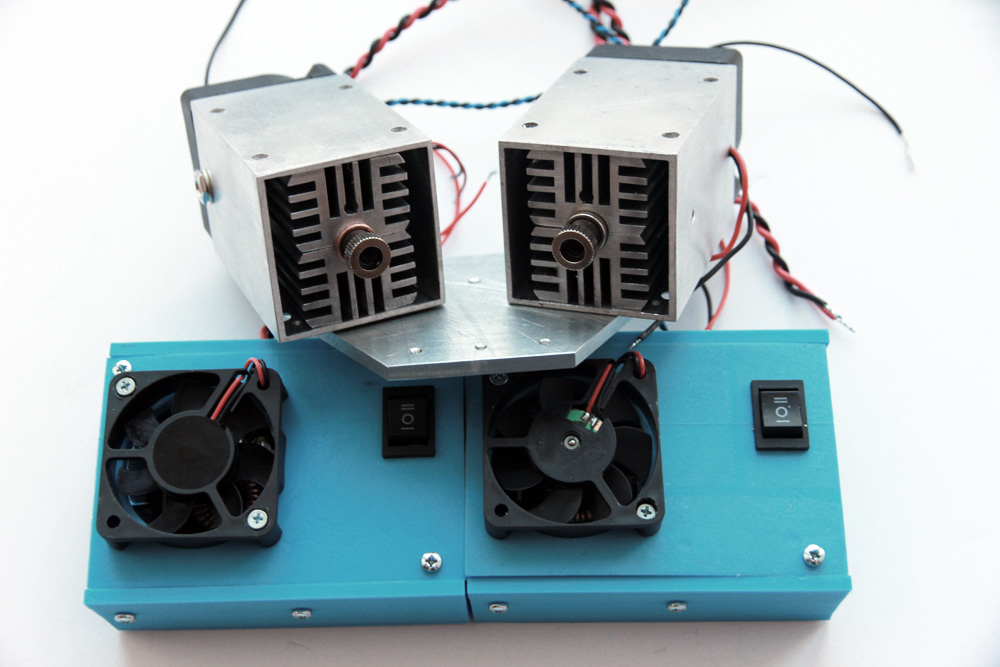

- 20 watt double-beam laser

Over time, we realize that improvements have been made in the development of each tool. Endurance 10 / 10+ / 20 watt lasers for instance, distinguish themselves from others of the same range thanks to their ability to cut 3-4 mm of plywood and wood quite easily and engrave on almost any surface: steel, stainless steel, copper, brass, stone, glass, etc.

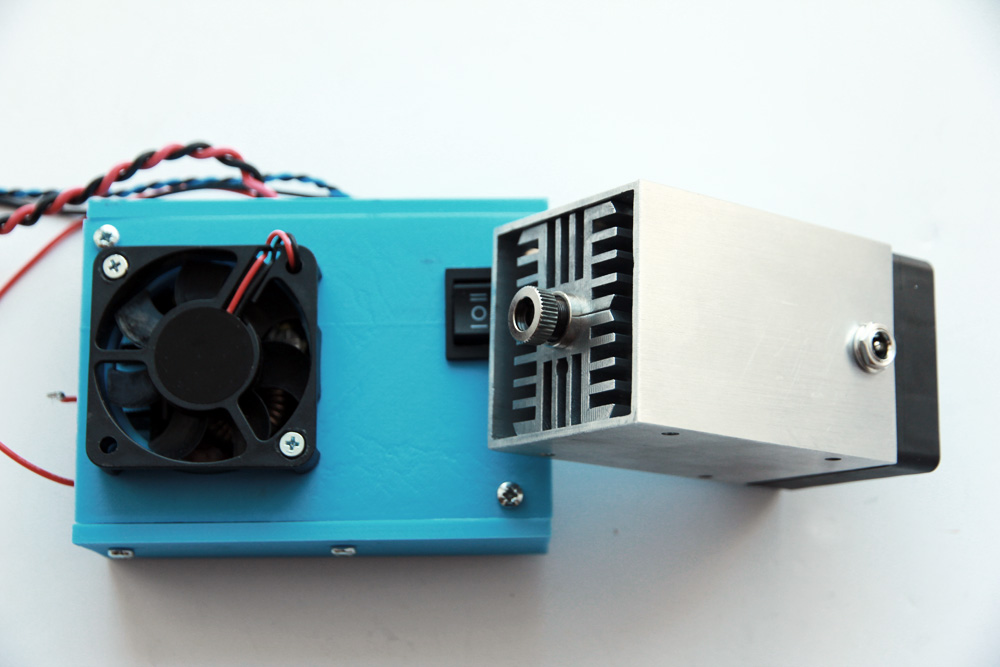

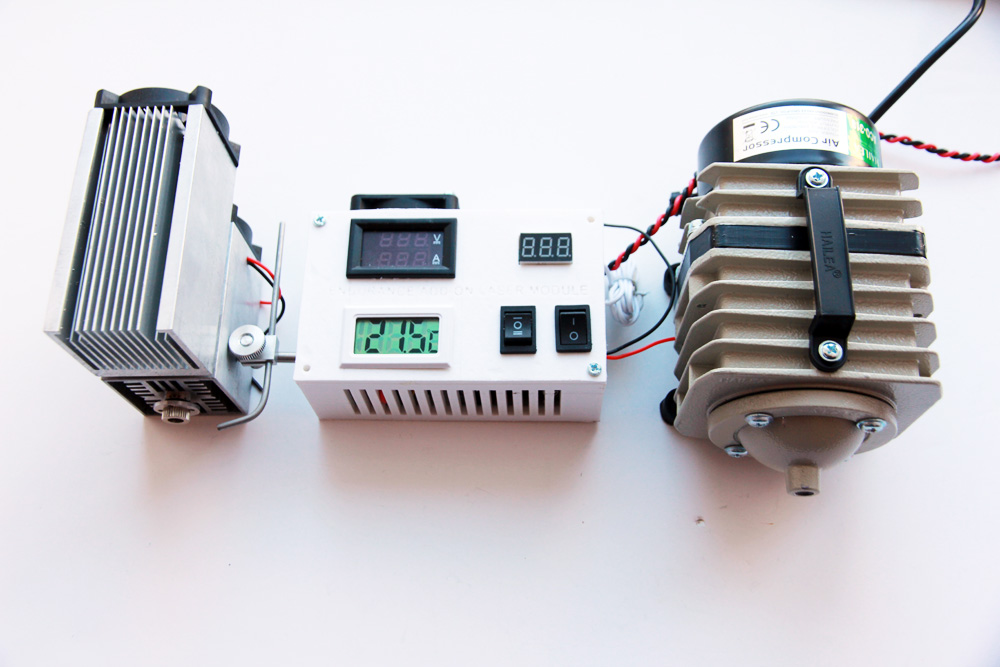

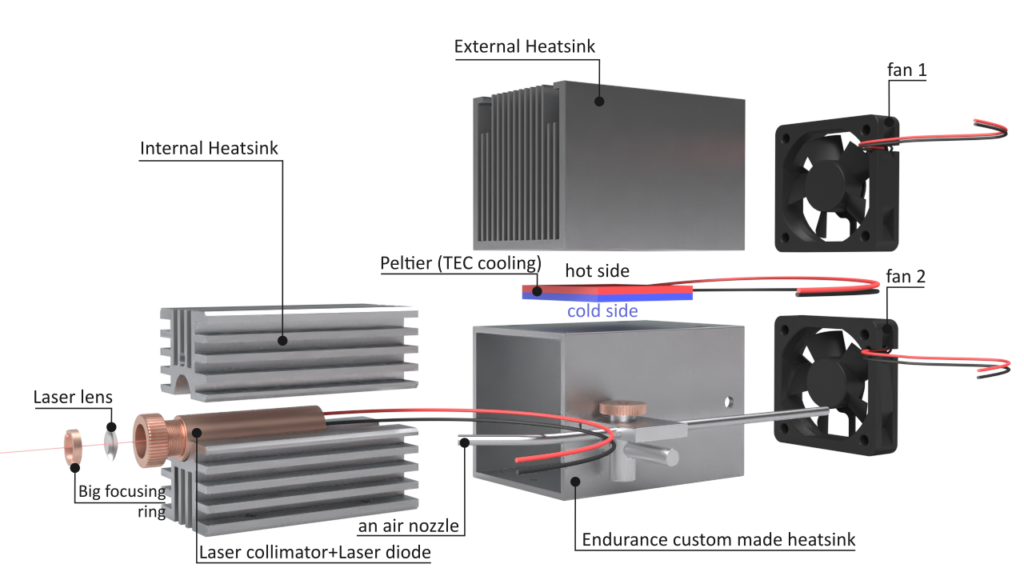

Speaking of the 10 watt+ laser, George Fomitchev explained that additional features include an air assist, a bigger focusing ring and a laser box able to measure temperature, voltage and current during the laser operation.

A bigger focusing ring allows to keep the laser focused all the time as opposed to many Chinese analogs and advanced TEC (Peltier) cooling allows laser diode to remain cold all the time. Furthermore, according to the CEO, the 10 watt+ laser attachment would be one of the most advanced one, suitable for any 3D Printer or CNC machine.

What’s in the pipeline?

Exploring new abilities for its lasers

As nothing is perfect, Endurance is always striving to deliver more powerful tools. As far as 10/10+/20-watt lasers are concerned, the company seems to have hit its limitations working with 445 nm NICHIA laser diodes. That’s why, they are exploring new optics opportunities, fiber coupling and laser beam combining.

Laser Research with Nescel & exploring abilities of FAP800 by Coherent

Endurance has also collaborated with Nescel and Coherent to explore a variety of new modules.

“Nescel offers a 10-watt 520 nm laser model while Coherent offers an FAP800 with 15 / 25 / 30 / 45-watt laser modules with an NIR wavelength of 808 nm. But to operate these lasers you need specific voltage and current settings. Thus, an FAP800 Coherent requires 2V and 40A that is not typical, and to find affordable AC DC or DC DC converters is a challenge. That is why we have developed our own AC DC with an adjustable voltage of 1.5-3V and current settings. Now this AC DC converter is available for public.

Our first launch of the FAP800 25-watt laser module brought us a good measure of optimism.

However, testing and running of the Nescel 520 nm 10-watt AVG did not satisfy us and we decided to leave that technology for a while”, said George Fomitchev.

Applications

“We are exploring new ways of using diode lasers in daily life and helping CNC users and enthusiasts try them in action. The most popular way of using is laser marking (etching) on metallic surfaces and laser cutting of acrylic, wood and plywood”, said Endurance’s CEO.

Furthermore, Endurance also welcomes users and enthusiasts to share their applications of the products. Florian Kelsch, for instance, a faithful customer opened a new business with the company’s 10-watt laser. Today, he masters all the contours of laser cutting and laser engraving on metallic surfaces.

Latest applications of laser attachments can be seen in the company’s videos on YouTube.

However, it should be noted that, during the last four years, Endurance has sold over 2000 laser units worldwide and the quality of the company’s products would not be the only reason that explains this success. In fact, Endurance is one of those companies that has been able to surround itself with a good community. In addition to feedbacks given on its social networks, Facebook, Twitter, and YouTube, the company also integrates a group of experts that supports customers throughout their journey.

George Fomitchev shares his satisfaction for all this support: “I personally believe that good –friendly and supportive community is very important for any company and any business especially if you are a startup. I am lucky that our Facebook community get together a lot of knowledgeable, supportive and interesting people. Even when our customers find some missing points they are not getting pissed off or angry – they are involved and help us to improve. There are always places to improve your business. The good thing about community is that many customers care about your product – they want to help and I must say that is touching and inspiring when people send you kind words.”

In order to thank this community and to inspire users to discover new applications of the products, the US-based manufacturer often launches Giveaway and contests. More than 1000 participants even took part in the latest contest that was launched in February.

Lastly, Endurance is committed to supporting education worldwide. That’s why, the company donates laser attachments to academics and students who are willing to take advantage of its technological tools.

“Endurance is planning to donate more lasers in the future and we are confident that there are much more ways to use diode lasers in other fields: pharma, microbiology, medicine, quantum physics, classical physics, chemistry, etc.”, concluded George Fomitchev.

For further information, follow us on our social media and subscribe to our newsletter! Would you like to be featured in the next issue of our digital magazine? Or subscribe to 3D Adept Mag? Send us an email at contact@3dadept.com

//pagead2.googlesyndication.com/pagead/js/adsbygoogle.js (adsbygoogle = window.adsbygoogle || []).push({});