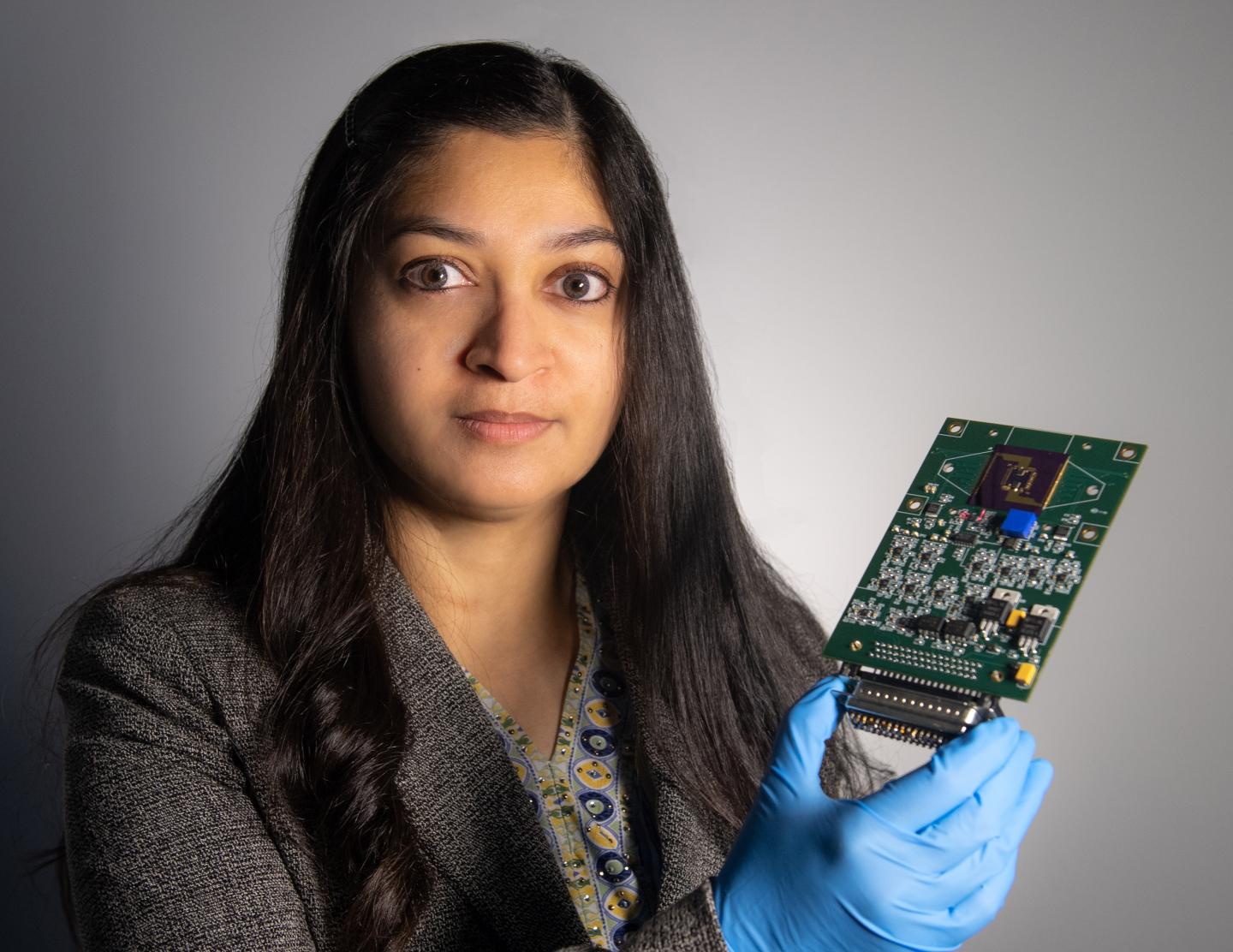

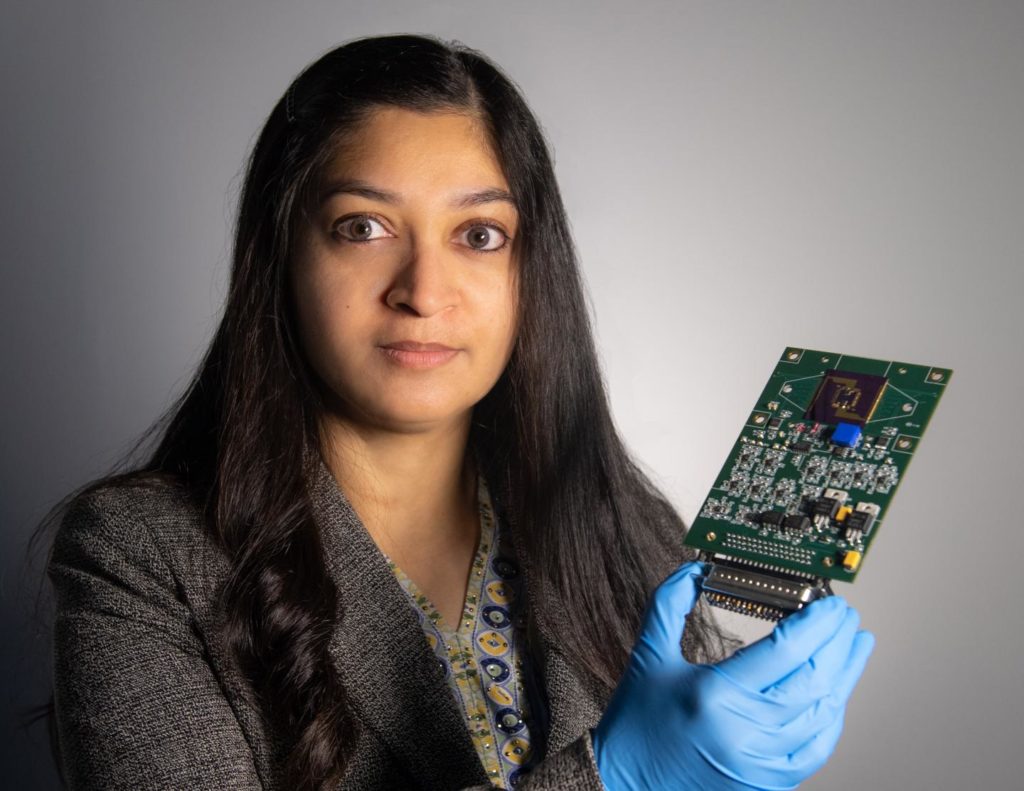

Technologist Mahmooda Sultana holds an early iteration of an autonomous multifunctional sensor platform, which could benefit all of NASA’s major scientific disciplines and efforts to send humans to the Moon and Mars.

CREDIT: NASA/W. Hrybyk

Mahmooda Sultana is the lucky scientist that received a $2 million funding from Nasa. The NASA technologist will develop a field that is not yet fully explored in the industry. By funding this project, NASA aims to develop all disciplines capable to facilitate the transportation of humans from earth to the Moon and Mars.

In this particular case, the developed platforms could enable the deployment on planetary rovers so that researchers can easily find small quantities of water and methane, or any element that might maintain astronaut health and safety.

The 3D printed sensor technology

The 3D printed sensor technology can sense everything from minute concentrations of gases and vapor, atmospheric pressure and temperature, and then transmitting that data via a wireless antenna — all from the same self-contained platform that measures just two-by-three-inches in size.

Mahmooda Sultana and her team will undertake a 2 years project to push forward the autonomous multifunctional sensor platform. 3D printing will enable Sultana to produce a suite of sensors at fast pace rather than producing them one after another before their complete assembly to other components.

Furthermore, what is interesting is that Sultana is bringing creativity at the technical level by printing on the same silicon wafer partial circuitry for a wireless communications system. The latter would communicate with ground controllers, further improving instrument design and construction.

Once printed, the sensors and wireless antenna will be packaged onto a printed circuit board that holds the electronics, a power source, and the rest of the communications circuitry.

“The beauty of our concept is that we’re able to print all sensors and partial circuity on the same substrate, which could be rigid or flexible. We eliminate a lot of the packaging and integration challenges,” Sultana said. “This is truly a multifunctional sensor platform. All my sensors are on same chip, printed one after another in layers.”

For further information about 3D Printing, follow us on our social networks and subscribe to our newsletter

Would you like to subscribe to 3D Adept Mag? Would you like to be featured in the next issue of our digital magazine? Send us an email at contact@3dadept.com

//pagead2.googlesyndication.com/pagead/js/adsbygoogle.js (adsbygoogle = window.adsbygoogle || []).push({});