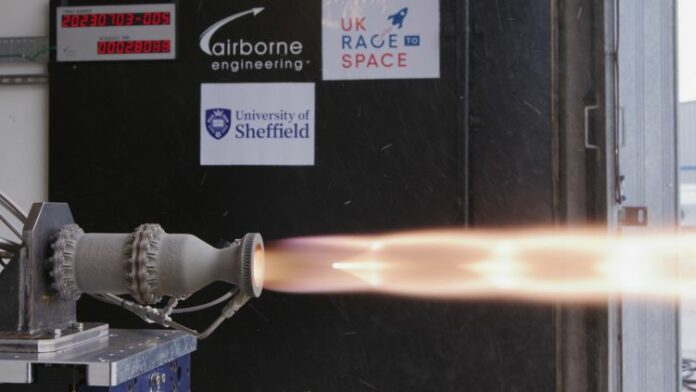

The engine would be the first to be 3D printed by students in the UK and the most powerful student-built liquid rocket engine

A team of Sheffield engineering and science students additively manufactured the ‘SunFire’ engine, that uses both fuel and an oxidiser rather than breathing in oxygen like a jet engine.

The liquid rocket engine is described as the most powerful student-built engine of its type. It would also be the first that is regen-cooled – an engine that uses fuel to cool the combustion chamber before it is burnt, which increases the engine’s efficiency and saves weight.

The SunFire engine was test fired at Airborne Engineering at the Westcott Space Cluster and 3D printed at the Satellite Applications Catapult with the print process optimisation work done under the MAPP EPRSC future manufacturing hub.

Dr Alistair John, Deputy Director of Aerospace Engineering at the University of Sheffield, who supervised the team, said: “Additive manufacturing (3D printing) is increasingly being used by rocket companies such as SpaceX as it allows you to build complex, lightweight custom geometries that would not be possible using traditional methods. For example, the cooling channels in our engine, which stop the engine melting despite the 2,000°C combustion temperature, can only be made using 3D printing.”

The Sheffield students have successfully hot fired – or tested – the engine as part of a week-long competition called Race to Space, in which teams of students from universities across the UK tested rocket engines they have built over the last two academic years.

The Race to Space competition week is believed to have set an unofficial world record itself, for the number of different hybrid/liquid rocket engines hot-fired for the first time on one site in one week.

Engineering graduate and former Sunride Project Manager, Dana Arabiyat – who is now working at Rolls-Royce, said: “Two years and countless hours of hard work later, the successful hot-fire of our engine got us jumping for the most unforgettable five seconds of our lives! This achievement is a testament to the incredible talent and commitment of our Project SunFire team members and leads, and to the tireless mentorship and supervision of Dr Alistair John.”

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure you send it to contact@3dadept.com