The development and improvement of depowdering solutions is not solely based on machines. A key part of their functionality and their ability to achieve an automated and repeatable work is based on the software capabilities they leverage. That’s in any case one thing we learn from machine manufacturer Solukon.

At the beginning – in 2018 -, we only talked about the company’s depowdering machines with the intelligent software solution developed in collaboration with Siemens as key capability. Since then the SFM-AT800-S was then the very first and only machine to benefit from this solution.

Named SiDAM, the software was the brainchild of Dr. Christoph Kiener, Principal Key Expert on Functional Design for Manufacturing at Siemens Technology. “Vibration-excited powder behaves almost like a fluid when it flows out. That’s how we quickly realized that we could find success by using path identification as well as particle and flow simulation in the software,” says Kiener.

What we didn’t know is that the software prototype was only made available to a select number of Siemens’ and Solukon’s development partners. Today, Solukon is the exclusive licensee. It has developed it into a corporate Solukon product, and is now bringing it to the AM market under the new name, SPR-Pathfinder®, allowing its customers to purchase licenses for the first time.

“It’s a logical step for us to license the depowdering software exclusively to Solukon, thereby enabling the pioneer in industrial depowdering to offer the market an even more effective product,” says Dr. Georg Bodammer, Senior Venture Director at Siemens Technology Accelerator. “This way, customers can get everything from a single source: the market-leading depowdering system and the exclusive, intelligent software.”

A perfect timing and a meaningful name

The timing is perfect for the Solukon team as the company embarked on a journey to improve its digital solutions. Remember, last year saw the development of digital tools on Quality Assurance, by integrating automation and new IoT Solutions for depowdering.

This year, the company goes one step further as the SPR-Pathfinder® software makes the digital twin of a part usable in post-processing for the first time. I love the capabilities of digital twin technologies.

“In contrast to conventional manufacturing processes, 3D printing uses the part’s digital twin. To date, however, this was only utilized during the printing itself. With SPR-Pathfinder®, the part’s digital twin can now also be used during depowdering. This is how we ensure that the potential of the digital twin can be used to the fullest in post-processing as well,” Andreas Hartmann, CEO/CTO of Solukon, recalls.

I am aware of the challenges to implement digital twin in (additive) manufacturing environments, so seeing such solution pushed forward sounds like good music to my ears.

What’s even more interesting is that, in this specific case, the name SPR-Pathfinder® has not been given randomly. Solukon deliberately drew on the established depowdering technology Smart Powder Recuperation, also known as SPR®. The latter generally involves automated rotation on two axes as well as adjustable vibration in a safety-controlled atmosphere. The algorithm-based SPR-Pathfinder® calculates the ideal motion sequence for the most complex geometries, finding the best path to allow the powder to flow out completely, a press release reads.

However, a new name does not necessarily mean new procedure. As a matter of fact, the main steps to leverage the intelligent depowdering solution remain the same: upload the file to SPR-Pathfinder® – set the calculation parameters – specify the file storage location – start the calculation – transfer the cleaning program to the Solukon system.

More on the process operation

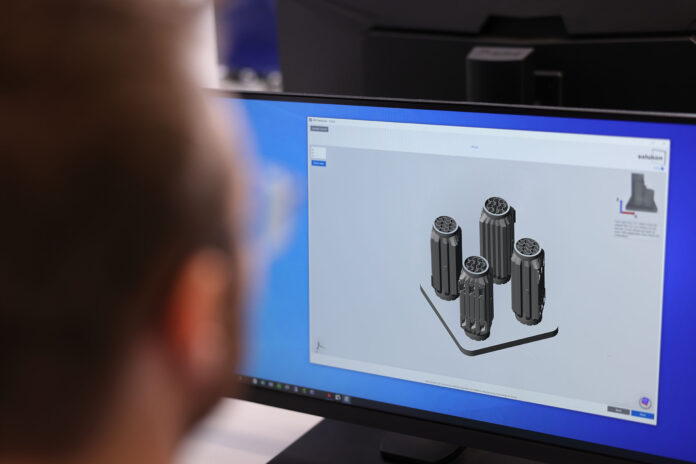

To remove excess powder from complex internal structures, SPR-Pathfinder® uses the build job’s CAD file to calculate the ideal motion sequence in the Solukon system. The SPR-Pathfinder® calculations are based on a flow simulation that analyzes the part’s digital twin. The individually calculated motion sequence is then read by the Solukon system, which in turn runs the programmed paths. This ensures that even the most complex parts are cleaned—in record time and without any human programming effort, the company explains.

Another important thing to keep in mind is that SPR-Pathfinder® runs as on-premises software —this means that users can only leverage it on the company’s own devices (PC or notebook), not in the cloud. Each license is bound to a device and is always valid for the current version at the time of purchase.

Visitors at Formnext 2022 will have the opportunity to discover how SPR-Pathfinder® software depowders even the most complex geometries in an SFM-AT800-S, at Solukon’s booth in Hall 12.0, B21. In addition to the software, all four metal systems will also be on display. We’re certain the impressive parts in the depowdering systems will once again attract a great deal of attention. For the first time ever, Solukon will also address the unpacking and depowdering of polymer parts at its booth. Diagrams and videos will explain the design of the SFP770, the company announces.

In case you miss Formnext, note that Solukon customers can also test SPR-Pathfinder® free of charge and without obligation. To do so, they would need to register for a 30-day trial version on Solukon’s website.

Remember, you can post free of charge job opportunities in the AM Industry on 3D ADEPT Media or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com