The additive manufacturing industry is full of collaborations on material+printer solutions to advance industrial 3D printing. However, very of few them currently address DLP 3D printing tooling applications.

Two companies that share the same vision for these applications are materials producer Covestro and 3D printer manufacturer EnvisionTEC. By joining forces, they aim to lower the entry barriers for industrials who want to produce molds for low volumes or parts with detailed features faster and more economically.

A solution for 3D printing injection mold tooling.

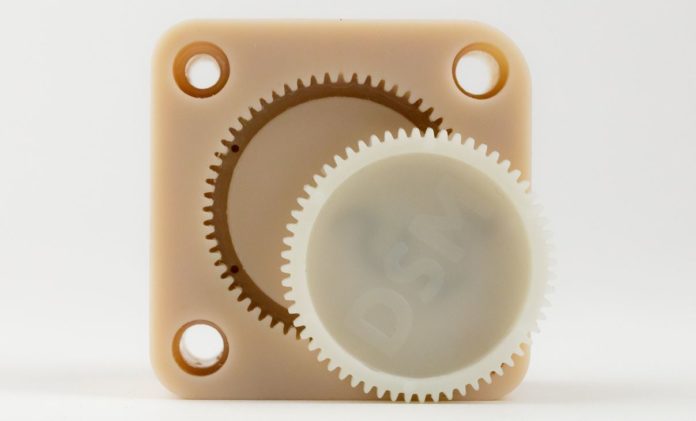

According to Covestro, the market did not have any solution that met the stringent industry-required properties in terms of dimensional stability and minimal warpage. The patented material formulation from e-PerFORM™, optimized for EnvisionTEC’s equipment, brings the benefits of Somos® PerFORM to a faster and more economical printer technology.

Somos® PerFORM may sound familiar, as it is a series of resins, developed by DSM AM unit– now a Covestro company. Those resins are also used on Origin’s 3D printing systems and Stratasys.

To ensure the compatibility of this material with EnvisionTEC, both teams optimize print parameters and verified Covestro’s new DLP resin e-PerFORM™ on EnvisionTEC’s Perfactory P4K series printer. EnvisionTEC further tested e-PerFORM™ resin with key molding institutes to validate the material’s performance. Completed mold trials demonstrate that e-PerFORM™ resin, with high stiffness and high temperature performance, behaves similarly to stereolithography resin Somos® PerFORM for injection molding tooling.

Tests confirm suitability for rapid mold making

Tests done by Polyvia, the French Federation of Plastics and Composites, confirm the suitability for rapid tooling. Guy Chrétien, Process project manager at Polyvia confirmed: “We tested the new e-PerFORM™ resin printed on the EnvisionTEC P4K printer and demonstrated that we could achieve very good results in part fidelity and in the number of shots molded in both polypropylene and glass-reinforced nylon. With the cost effectiveness and print speed of the P4k platform and with the properties of the e-PerFORM™ resin, this creates additional opportunities for rapid tooling.”

Hugo da Silva, Head of Additive Manufacturing at Covestro commented: “By working closely with our partner EnvisionTEC, we developed a material that meets critical needs voiced in the market: improved dimensional stability and minimal warpage for optimal functionality. The validation and proven solution with their P4K printers will help accelerate the adoption of additive manufacturing of injection mold tooling.”

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure you send it to contact@3dadept.com