Home =

RenAM 500Q - search results

If you're not happy with the results, please do another search

What happens if Renishaw co-locates its Additive Manufacturing teams?

Renishaw is currently considering to co-locate its additive manufacturing teams. The global engineering technologies company is consulting its 120 affected employees at the Stone site. Being an AM company involves a certain structure. Indeed,...

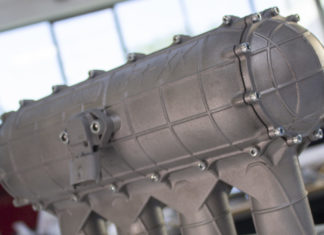

Renishaw 3D printed a manifold part that serves in Formula Student competition

Renishaw assisted the Brunel University London race team that participated at the

Formula Student (FS) competition. The Engineering company 3D printed in metal a

manifold part for the team’s BR-XX car, which was used to compete...

Atherton to produce its bike frames using Renishaw Additive Manufacturing

The Atherton siblings, Gee, Rachel and Dan alongside with Piers

Linney of Dragons’ Den fame have recently launched a

bike brand, Atherton and have chosen Renishaw to additively

manufacture titanium lugs for their bike frames.

Acknowledged as the...

SANDVIK chose Renishaw’s Additive Manufacturing Systems to improve materials development, AM process and post-processing

Sandvik is a global engineering company that integrates an AM unit has installed several Renishaw RenAM 500Q quad laser machines to improve materials development, AM process and post-processing.

Sandvik specializes in materials technology and has...

Formnext Preview: Xaar, Techniplas, EOS, 3D Systems, Raylase, Renishaw, Colossus (Part 2)

In this second series of announcements, visitors of Formnext can expect concrete applications of the technology in sectors such as the automotive, in addition to new technologies.

Xaar and its inkjet printhead technology

After creating...

IN(3D)USTRY – Key moments with AM companies: Renishaw, Trumpf, BigRep & PIEP

Even though the medical industry was at the heart of exhibitions held in Barcelona last week, including IN(3D)USTRY, it should be noted that all sectors of activity were represented in this latter event.

Manufacturers of...

Renishaw reduces AM build times with TEMPUS technology™

Renishaw has launched TEMPUS technology™, which enhances the productivity of its AM systems without hampering quality.

The new 3D printing technology reduces build times by 50% and will help in the usage of AM as...

3D metal printing: the potential of the manufacturing process

According to a market research carried out by Reportlinker, 3D metal printing has proven itself on the additive manufacturing process and must still be developed in order to reach its full potential. Indeed, this...