Even though the medical industry was at the heart of exhibitions held in Barcelona last week, including IN(3D)USTRY, it should be noted that all sectors of activity were represented in this latter event.

Manufacturers of various additive manufacturing systems and materials showcased innovations made with their technology.

A few exchanges with exhibiting companies enabled us to determine which is the most demanding sector on the Spanish market, prospects for development of some companies as well as challenges encountered by others.

First of all, let’s note that, unlike others, this exhibition did not showcase a vast array of machines. For Miquel Serrano, Managing Director of Fira Barcelona, organizer of IN(3D)USTRY, one of the objectives of the exhibition was not only to present a set of machines from various manufacturers but above all to highlight case studies from these technologies.

Industrial 3D printing: the potential of additive manufacturing for the aerospace industry

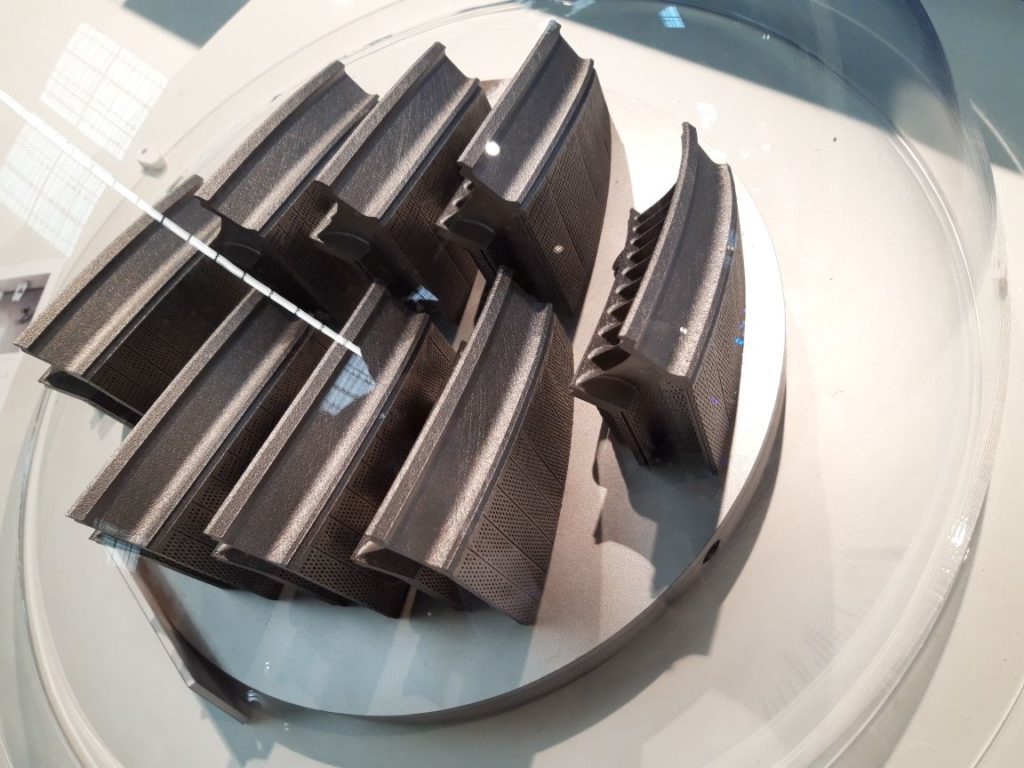

Acknowledged companies such as Arburg, Renishaw and Trumpf showcased their additive manufacturing system at IN(3D)USTRY. Their presentations also revealed that the aerospace industry is one of the most demanding sectors in Spain.

Trumpf carried out a live demonstration of the TruPrint 1000, its additive manufacturing system designed for the production of complex components. It only took a few minutes to install the machine. Production details could be read on an intuitive touchscreen and according to the expert, the machine can produce up to 80% more parts at the same moment using the multilaser option.

Leonardo Marques from Renishaw, thereafter presented the famous RenAM 500Q, which was unveiled last year at Formnext.

Like the TruePrint 1000, this system also integrates laser technology that allows production savings in a production process. What makes the RenAM 500Q special is the fact that it is designed for one type of alloy at a time.

So, if a specific type of alloy has been qualified for the manufacturing process, the machine will exploit the same alloy for a family of applications. In addition, Leonardo laid emphasis on the importance of software, which makes it possible to optimize the additively manufactured part in order to reduce its weight.

Lastly, according to him, the key role of the aerospace industry is to “create the validation process, which will be used to create parts using additive manufacturing”.

At Formnext 2018, Renishaw will unveil a new 3D printing system…

Large format 3D printing: raising awareness in order to foster the adoption of 3D printing

Wasp and BigRep have highlighted large format 3D printing. BigRep was represented by its Valencia-based supplier “Multi3DPrint”. The company showcased a few examples of applications made with its 3D printer ONE.

Speaking of challenges encountered by the German manufacturer in Spain, Gesa Schneider, Sales Channel Manager EMEA at BigRep, explained that the Spanish market is strongly dominated by foundries and although “companies are fully aware of the potential of 3D printing, they are still reluctant to fully adopt the technology.”

Taking advantage of natural resources to produce new materials

PIEP, an institution created in 2001 in collaboration with the University of Minho in Portugal, aims to foster research and development in polymer engineering.

The institution is currently developing biomaterials for 3D printing, injection molding and extrusion. In the long run, it aims to develop a new carbon fiber based on natural resources. This material will then be used for both industrial and non-industrial applications.

For further information about 3D Printing, follow us on our social networks and subscribe to our newsletter!

Would you like to be featured in the next issue of our digital magazine? Send us an email at contact@3dadept.com

//pagead2.googlesyndication.com/pagead/js/adsbygoogle.js

(adsbygoogle = window.adsbygoogle || []).push({});