Home =

defects - search results

If you're not happy with the results, please do another search

Phase3D correlates AM build anomalies to part defects for the U.S. Air Force and NASA

Phase3D, an expert in-situ monitoring for additive manufacturing, correlates measurable metal powder bed fusion build anomalies to final part defects in real-time. This work was done for the United States Air Force and NASA,...

Isar Aerospace relies on the nebumind software to automatically identify defects of metal 3D printed parts

With thousands of layer images to analyze when searching for errors, it’s easy to miss a critical defect that will result in the non-validation of a part. The fact is the powder recoating conducted...

John Hopkins can identify Additive Manufacturing defects with nanoseconds

Remember when I told you a growing number of defect analysis tools are being developed and commercialized? As a reminder, some of the most common defects created during AM — and among the hardest...

Identifying defects by “listening” for them as they occur in a metal 3D printer

Acoustic monitoring for detecting porosity in laser powder bed fusion could be viable.

In a recent article, we learned that one can identify defects in a laser powder bed fusion machine using the Materialise Quality...

Identifying defects in metal 3D printed parts can lead to up to 70% savings in production costs. Materialise explains how and why.

As part of the additive production of a critical medical component, a defect identified after the post-processing phase made the team lose one HIP cycle, one day of post-processing and quality inspections, not to...

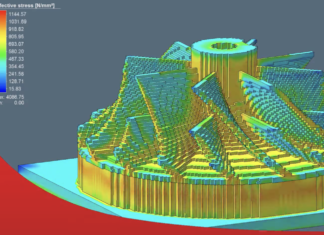

Hexagon and Raytheon Technologies to provide a simulation tool that predicts metal 3D printing defects

Hexagon, a global company that provides digital reality solutions, combining sensor, software and autonomous technologies, is working with aerospace company Raytheon Technologies to provide industries with a simulation tool that will enable evaluation and...

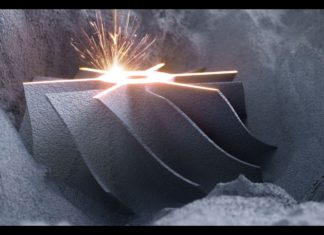

Another approach to avoiding defects during metal additive manufacturing

One of the challenges operators encounter while using laser powder bed fusion is the formation of tiny bubbles or pores during the printing process which lead to weak spots in finished 3D printed components.

These...

Apium Filament Dryer can reduce moisture-related additive manufacturing defects

The FDM manufacturing process often leads to moisture-related 3D printing defects which results in poor print quality. This might be caused by the type of filaments used. Indeed, when they integrate polymer, materials are...

What if Gold can detect defects in 3D printed parts?

At Vanderbilt University (USA), scientists would have developed a technique to bring out the defects that can be integrated in a 3D printed part. This technique consists in using gold particles that would make...

Invent Medical manufactures 3D printed helmets for cranial defects in babies

Invent Medical manufactures helmets that can treat craniosynostosis (cranial defects that often affect babies).

The company uses HP's Multi Jet Fusion technology in its manufacturing and explains in this video the benefits in terms of...