Home =

defects - search results

If you're not happy with the results, please do another search

AM-Flow unveils an enhanced version of its AM-Quality solution

Two years ago, to facilitate the transition from prototyping to series production, workflow automation company AM-Flow developed an AM In-Line Quality Control solution for the steps that follow the manufacturing process.

Simply put, this solution...

BigRep unveils DRYCON – A 3 in 1 machine that enhances industrial 3D printing. Here is how!

The manufacturer of large-format 3D printers BigRep has unveiled DRYCON, a drying, storage & annealing machine for optimal filament performance. Its dual chamber system perfectly complements industrial 3D printers to offer high-quality printed parts.

The...

3D4MEC & Fraunhofer IAPT to develop an advanced in-situ optical monitoring system for brass 3D printing

3D4MEC known for its Metal Additive Manufacturing services has collaborated with the Fraunhofer Research Institution for Additive Manufacturing Technologies (IAPT), to develop an advanced in-situ optical monitoring system for the 3D4BRASS printer.

Thetascan GmbH has...

Use of a new biopolymer nanocomposite for 3D printing bone grafts

The latest biopolymer nanocomposite material for bone grafts has been developed at the University of Waterloo. The University of Waterloo focused on offering optimal health and well-being via tech advancement, virtual care, and health...

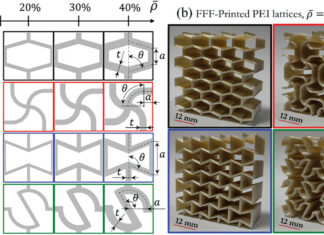

UK Researchers relied on the “enhancement factor” to develop 3D-printed lattices with advanced properties

Engineers in the UK and Italy are behind the research on the deformation mechanisms of 3D printed materials. The latter aims to provide insight into the balance of structural factors at play in the...

BLT launches powders for Additive Manufacturing, shares specific cases to highlight their capabilities

To provide more solutions to industrial companies, Bright Laser Technologies (BLT) has introduced a high-strength aluminum for Selective Laser Melting (SLM) and the BLT-Ti65 powder for Selective Laser Melting (SLM) and Directed Energy Deposition...

The use of HIP for critical 3D printed parts: introduction and applications

Hot isostatic pressing (HIP) is a process used to reduce porosity and increase density in powders, cast and sintered parts in a furnace at high pressure (100-200 MPa) and at temperatures from 900 to...

Makino and Fraunhofer ILT develop a process that can produce, coat or repair 3D printable complex geometries

The Fraunhofer Institute for Laser Technology ILT and Makino, a globally recognized manufacturer of machine tools collaborate together to develop a process that can efficiently produce, coat or repair complex geometries with high-strength materials.

With...

RAPID+TCT 2024: Hollywood meets Additive Manufacturing

With over 400+ exhibitors, 200+ conference speakers including 125 educational hours of industry-leading presenters, and 100,000+ attendees, this year’s RAPID + TCT show was a highly anticipated event. With California as a whole being...

ORNL researchers 3D print defect-free tungsten parts

Remember when I told you that tungsten’s hardness and extremely high melting point have always made it difficult to process via additive manufacturing technologies? Add to that the fact that the development of defects...