Home =

defect - search results

If you're not happy with the results, please do another search

Phase3D correlates AM build anomalies to part defects for the U.S. Air Force and NASA

Phase3D, an expert in-situ monitoring for additive manufacturing, correlates measurable metal powder bed fusion build anomalies to final part defects in real-time. This work was done for the United States Air Force and NASA,...

ORNL researchers 3D print defect-free tungsten parts

Remember when I told you that tungsten’s hardness and extremely high melting point have always made it difficult to process via additive manufacturing technologies? Add to that the fact that the development of defects...

Isar Aerospace relies on the nebumind software to automatically identify defects of metal 3D printed parts

With thousands of layer images to analyze when searching for errors, it’s easy to miss a critical defect that will result in the non-validation of a part. The fact is the powder recoating conducted...

John Hopkins can identify Additive Manufacturing defects with nanoseconds

Remember when I told you a growing number of defect analysis tools are being developed and commercialized? As a reminder, some of the most common defects created during AM — and among the hardest...

BellaSeno’s 3D-printed resorbable scaffold is used in critical-size large segmental radius bone defect

A team at the Hannover Medical School, Clinic for Trauma Surgery, led by Prof. Dr. med. Philipp Mommsen successfully used a 3D-printed resorbable scaffold in critical-size large segmental radius bone defect.

The scaffold was produced...

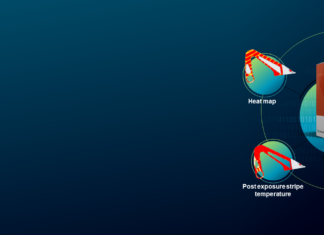

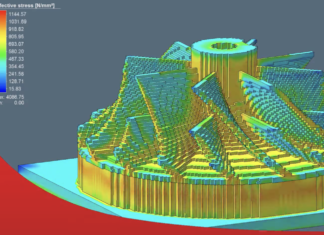

Hexagon and Raytheon Technologies launch Simufact Additive Process and Defect Analysis tool

More than a year ago, software giant Hexagon announced it was working with Raytheon Technologies to provide a simulation tool that predicts metal 3D printing defects. That solution is now ready to be commercialized....

Identifying defects by “listening” for them as they occur in a metal 3D printer

Acoustic monitoring for detecting porosity in laser powder bed fusion could be viable.

In a recent article, we learned that one can identify defects in a laser powder bed fusion machine using the Materialise Quality...

Identifying defects in metal 3D printed parts can lead to up to 70% savings in production costs. Materialise explains how and why.

As part of the additive production of a critical medical component, a defect identified after the post-processing phase made the team lose one HIP cycle, one day of post-processing and quality inspections, not to...

Hexagon and Raytheon Technologies to provide a simulation tool that predicts metal 3D printing defects

Hexagon, a global company that provides digital reality solutions, combining sensor, software and autonomous technologies, is working with aerospace company Raytheon Technologies to provide industries with a simulation tool that will enable evaluation and...

3D Printed fetus models help identify hurdles and reduce risks of surgery for a birth defect

Among the various birth defects that might require an in-utero surgery, there is spina bifida, a condition that can happen anywhere along the spine if the neural tube does not close all the way....