Home =

defect - search results

If you're not happy with the results, please do another search

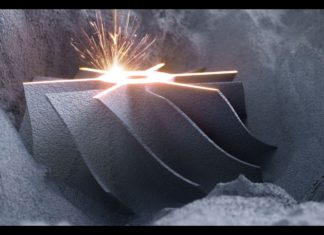

Another approach to avoiding defects during metal additive manufacturing

One of the challenges operators encounter while using laser powder bed fusion is the formation of tiny bubbles or pores during the printing process which lead to weak spots in finished 3D printed components.

These...

Apium Filament Dryer can reduce moisture-related additive manufacturing defects

The FDM manufacturing process often leads to moisture-related 3D printing defects which results in poor print quality. This might be caused by the type of filaments used. Indeed, when they integrate polymer, materials are...

What if Gold can detect defects in 3D printed parts?

At Vanderbilt University (USA), scientists would have developed a technique to bring out the defects that can be integrated in a 3D printed part. This technique consists in using gold particles that would make...

Invent Medical manufactures 3D printed helmets for cranial defects in babies

Invent Medical manufactures helmets that can treat craniosynostosis (cranial defects that often affect babies).

The company uses HP's Multi Jet Fusion technology in its manufacturing and explains in this video the benefits in terms of...

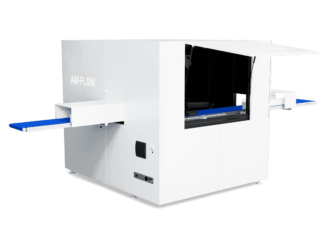

AM-Flow unveils an enhanced version of its AM-Quality solution

Two years ago, to facilitate the transition from prototyping to series production, workflow automation company AM-Flow developed an AM In-Line Quality Control solution for the steps that follow the manufacturing process.

Simply put, this solution...

Formnext 2024: Semiconductor manufacturers can now reduce their costs using TRUMPF 3D printers

TRUMPF's Additive Manufacturing (AM) technology enables the manufacturing of precise and efficient semiconductor manufacturing systems.

Marco Andreetta from TRUMPF states, “Semiconductor manufacturers can reduce scrap and cut costs with AM technology. The modern approach of...

The imperative of cybersecurity in Additive Manufacturing

Due to its strong reliance on digital data files and connectivity, AM by nature is subject to significant security exposures, from product malfunctions to intellectual property theft and brand risk, along with other new...

BigRep unveils DRYCON – A 3 in 1 machine that enhances industrial 3D printing. Here is how!

The manufacturer of large-format 3D printers BigRep has unveiled DRYCON, a drying, storage & annealing machine for optimal filament performance. Its dual chamber system perfectly complements industrial 3D printers to offer high-quality printed parts.

The...

3D4MEC & Fraunhofer IAPT to develop an advanced in-situ optical monitoring system for brass 3D printing

3D4MEC known for its Metal Additive Manufacturing services has collaborated with the Fraunhofer Research Institution for Additive Manufacturing Technologies (IAPT), to develop an advanced in-situ optical monitoring system for the 3D4BRASS printer.

Thetascan GmbH has...

Current possibilities of Additive Manufacturing in the cranio-maxillofacial field

A conversation with Prof. Florian Thieringer.

Among the wide range of specialists found in medicine, I have often called craniomaxillofacial surgeons gifted artists. Their ability to treat the soft tissue and skeletal structures of...