More than a year ago, software giant Hexagon announced it was working with Raytheon Technologies to provide a simulation tool that predicts metal 3D printing defects. That solution is now ready to be commercialized. Named the PBF Process and Defect Analysis solution (PDA), that solution is a combination of Simufact Additive’s and Raytheon Technologies’ Pratt and Whitney business.

The new feature helps designers and engineers evaluate the print outcome and test combinations of materials, geometries, and print processes without expensive and time-consuming physical test runs.

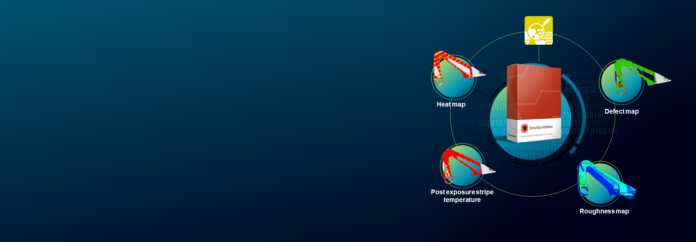

By predicting thermal history and defects swiftly, at the individual scan vector and powder layer level – the PBF Process and Defect Analysis solution enables operators to anticipate and mitigate risks associated with local defects, such as keyholing, lack of fusion, balling up, and surface roughness.

Jeff Robertson, Hexagon’s director of global business development points out which main challenge is tackled by PDA: “The ability to evaluate full laser powder bed fusion (L-PBF) parts on the meso-scale will reduce the effort to achieve part certification and thereby support industrialization of metal 3D printing.”

PBF Process and Defect Analysis can be incorporated before Simufact Additive’s Metal Powder Bed Fusion (MPBF) process simulation, to identify the best process settings to achieve a defect-free part. Subsequently, Simufact Additive’s detailed simulation of the MPBF process based on the identified settings can be used to calculate part distortions after both the build and post-build stages. One can then compensate for the distortions on the part and export the compensated part for the physical production, a press release says.

It’s too soon to say it’s a trend, but a growing number of defect analysis tools are being developed and commercialized. While they are only compatible with Metal Laser Powder Bed Fusion (L-PBF) now, these developments are a good sign software providers are going the extra mile to enhance the AM process.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter: Facebook, Twitter, LinkedIn! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com