Who recently purchased what? And who will distribute what? This edition of “news roundup” covers multiple purchases and 3D printing partnerships across the world.

Xerox and Siemens

Xerox® Elem™ Additive Solutions, the AM business of Xerox, announced a new partnership where it will support Digital solutions provider Siemens’ metal AM activities. The announcement follows the recent acquisition of ElemX by ORNL.

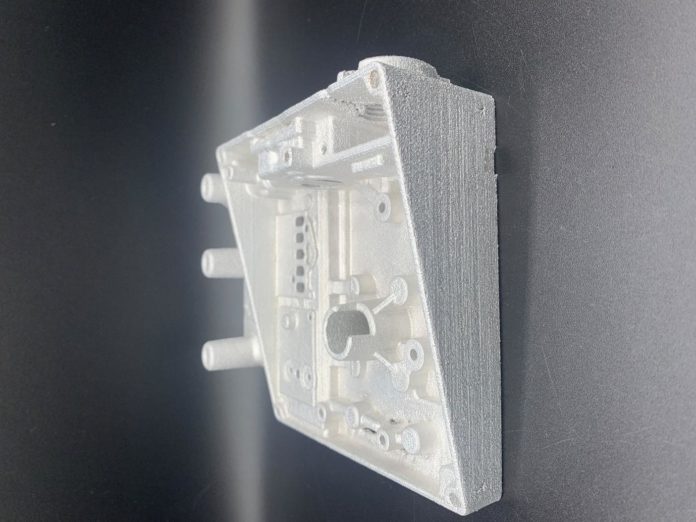

Siemens has purchased an ElemX metal 3D Printer, adding it to its fleet of additive machines inside their Charlotte Advanced Technology Collaboration Hub (CATCH). The CATCH facility focuses on the industrialization of additive manufacturing, working with machine builders, material suppliers and end-customers.

As a reminder, the ElemX leverages Xerox’s liquid metal AM that uses cost-effective aluminum wire and incorporates the state-of-the-art Siemens SINUMERIK 840D sl control platform with its embedded digital twin technology to optimize the printing process.

Farcco Tecnologia becomes a new distributor for VBN Components’ wear resistant alloys in Brazil

For the past few years VBN Components has been expanding its sales channels and partner network, and now the turn has come to Brazil. The company has added Brazilian Farcco Tecnologia as a distributor ofVBN’s Vibenite® materials and services in Brazil. Farcco is a distributor of Industrial Equipment for Additive Manufacturing of Metals, Engineering Polymers and Bio Printing, Maintenance of CNC Equipment.

Vibenite® the brand name of VBN Components’ wear-resistant alloys used in additive manufacturing (AM). The collaboration will include sales representation, engineering support, and technical consulting for Vibenite® AM powder feedstock and built parts within the Brazilian territory.

Through the partnership Brazilian industries will now have local access to the AM technology for producing the world’s hardest steel, as well as one of the few additively manufactured “cemented carbide” materials — the hybrid carbide Vibenite® 480. Vibenite® components can be produced in single units as well as in larger batches, and a customer can buy either manufacturing services or a Vibenite® license to produce in-house.

“Brazilian companies are very interested in Additive Manufacturing as a pillar of industry 4.0. The goal for the partnership with VBN is to give even more traction to the adoption of Additive Manufacturing through supportive resources and technical assistance, as well as the development of new products, applications, and more AM sites, making Additive Manufacturing increasingly common in Brazil”, says Fabio Sant’ Ana, Director of Farcco.

Russell Finex helps Chinese additive manufacturing (AM) plant to streamline its powder processing

Companies like the Chengdu Tianqi Industry Group strive to improve the Chinese AM market by building reliable 3D printing centres to meet rising demand. To help with this, the group contacted OEM Russell Finex to replace their manual sieve with an efficient and safer automated solution to process their titanium AM powder.

After a consultation, the Russell AMPro® Lite was recommended as an innovative alternative to meet Tianqi’s processing requirements. The machine was set up for powder reclaim from the 3D printer chamber. Screening powder at a much faster rate so it could be moved on to the next stage of processing. In addition to increasing sieving capacity, the Russell AMPro® Lite minimized product waste and improved operator safety. The contained system was ideal to prevent powder leakage into the air, as well as preventing contaminants from getting into the powder.

The Russell AMPro® Lite is ideal for safeguarding the quality of your AM powders while boosting production rates. The design also lends itself to easy disassembly and cleaning to minimize production downtime while improving hygiene.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com