Updated on May 08th

We have already written about several initiatives from Stratasys. The 3D printer manufacturer is one of the rare AM companies to record the most significant sales of 3D printers to combat Covid-19. He also provides both pro bono 3D printing services and commercial support to help flatten the curve.

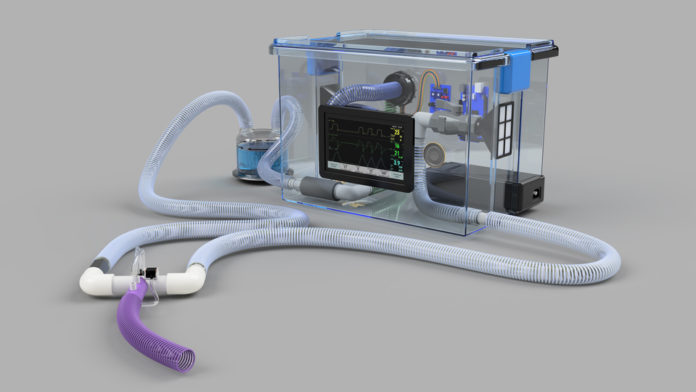

Following the recent CoVent-19 Challenge the Industrial FDM specialist launched, more than 200 ventilator designs have been submitted for a rapidly deployable, minimum viable ventilator.

For the final round, seven teams have been selected to participate and will be building working prototypes for testing by a team of judges led by a dozen anesthesiology resident physicians from Massachusetts General Hospital.

Phase 1 submissions included teams from 43 different countries, including Algeria, Bangladesh, Canada, Egypt, Greece, India, Malaysia, the Netherlands, Poland, Singapore, Spain, the United Kingdom, and the United States. The finalist teams are:

- SmithVent, a team of Smith College (Northampton, Mass.) engineering alumni and friends.

- CoreVent, submitted by Ross Hunter of Armadilla Ltd. (Edinburgh, Scotland)

- InVent Pneumatic Ventilator, submitted by fuseproject, a design and innovation firm (San Francisco), Cionic, a medical device technology company (San Francisco), and a mechanical engineering team from Accenture (Seattle).

- RespiraWorks, a global team of dozens of engineers, healthcare workers and other professionals with a focus on developing countries and low-resource communities.

- OP Vent, submitted by a team from Nvidia (Santa Clara, Calif.), Waymo (Mountain View, Calif.), Stanford University (Palo Alto, Calif.), and VA Palo Alto Health Care System.

- Lung Evolve, submitted by an engineering team from the Universidad Nacional (Bogotá, Colombia) and Universidad Pontificia Bolivariana (Medellín, Colombia).

- Baxter Ventilator, submitted by a team of educators, students, and alumni from Baxter Academy for Technology and Science, Portland, Maine.

In addition to hosting the challenge on its GrabCAD site, Stratasys has provided a team of three application engineers to work with the seven finalist teams to help them build working prototypes utilizing Stratasys 3D printers as needed. The prototypes will be evaluated using a test bed to determine which design provides the best combination performance against safety, reliability, manufacturability, affordability, and simplicity.

The goal is to declare a winner by the beginning of June, with the CoVent-19 Challenge residents then working with the winning team to bring it to market, including securing FDA approval for the device.

Other sponsors of the CoVent-19 Challenge include Ximedica, Valispace, HackFund and Yelling Mule.

Updated on March 30th

COVID-19: Stratasys Coalition to support over 150 organizations with 3D printed equipment (free of charge)

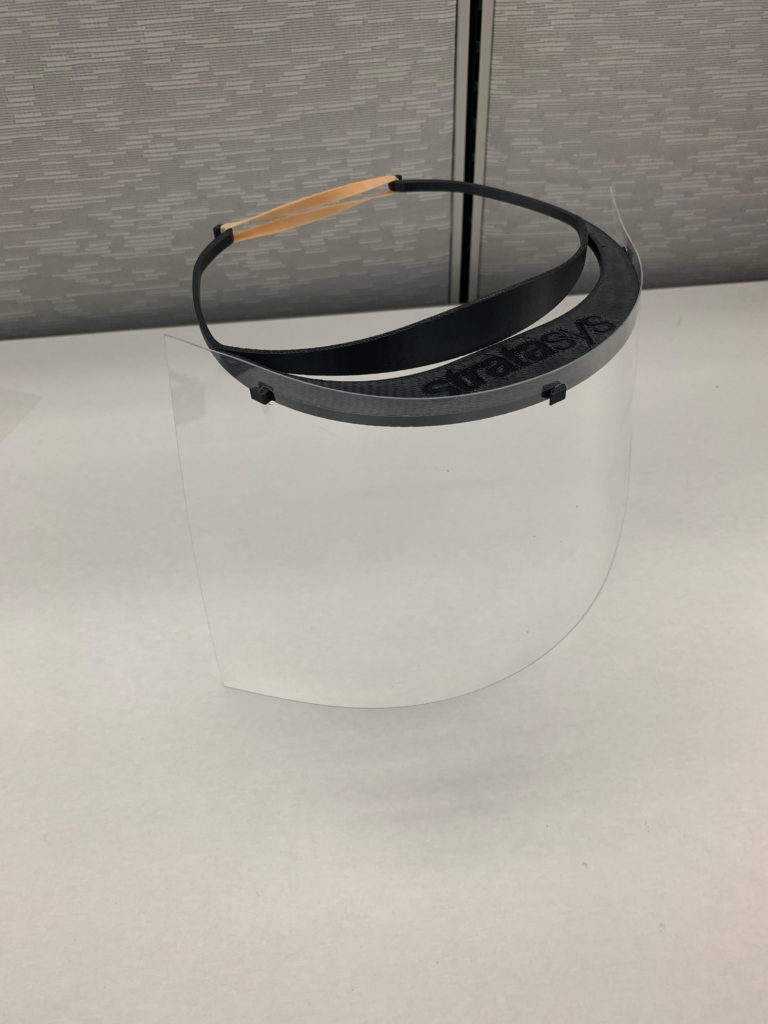

Last week, in an effort to confront the COVID-19 pandemic, Stratasys set an initial goal to produce 5,000 face shields at no cost to recipients through its own and partner resources. This support includes both a 3D-printed visor and a clear plastic shield that covers the entire face.

A first hospital received its equipment on March 25th. The manufacturer gathered a coalition of companies and universities to respond to the current needs of the healthcare industry. The manufacturer currently has received a demand of over 350,000 shields from hospitals and organizations.

The coalition should be able to produce more than 11,000 face shields this week, and 16,000 or more during next week.

Any 3D printing shop that wishes to help print at least 100 visors can fill out an online form to be invited to join the effort. For the U.S., Stratasys is using its GrabCAD Shop work order management software to assign orders from healthcare systems to each coalition member. In Europe, the company is serving as a hub to connect service bureaus with those requesting help, and has fielded offers and requests in most of the larger countries. The company also has posted the full face shield printing and assembly instructions for anyone to produce face shields on their own.

Published on March 23rd

COVID-19: Stratasys’ initial goal is to produce for free of charge 5,000 3D printed face shields by Friday, March 27.

A US-based hospital told Stratasys they use 1,530 disposable face shields every week even without the surge created by COVID-19 and is down to six days’ inventory on hand, with the pandemic still building momentum.

Spanning its GrabCAD software, Stratasys Direct Manufacturing and partner network with donated printing capacity across all regions, the FDM & Polyjet technologies specialist will produce 5000 face shields for that hospital by Friday, March 27th.

In the same vein, medical technology specialist Medtronic and Minneapolis-based Dunwoody College of Technology will provide support for the plastic shield material.

However, for now, the company’s operations with regards to this crisis are dedicated to the American region.

“We are humbled by the opportunity to help. We see additive manufacturing as an essential part of the response to the COVID-19 global epidemic,” said Stratasys CEO Yoav Zeif. “The strengths of 3D printing – be anywhere, print virtually anything, adapt on the fly – make it a capability for helping address shortages of parts related to shields, masks, and ventilators, among other things. Our workforce and partners are prepared to work around the clock to meet the need for 3D printers, materials, including biocompatible materials, and 3D-printed parts.”

To process requests from hospitals or organizations easily, the manufacturer has created a web page where hospitals can request 3D printed products to help with the crisis, organizations offer 3D printing capacity, or request 3D printers or material for medical- or safety-related purposes. In this regard, further instructions regarding the assembly of this mask will be posted on that webpage today.

Last but not least, an initiative led by anesthesiology residents of Massachusetts General Hospital called the CoVent-19 Challenge is planning to ask engineers and designers to help develop a new rapidly deployable ventilator and other innovative solutions to the ventilator shortage, and Stratasys plans to support the challenge and promote it via its GrabCAD community of more than 7 million professional designers, engineers, manufacturers and students.

Remember, you can post free of charge job opportunities in the AM Industry on 3D ADEPT Media or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com