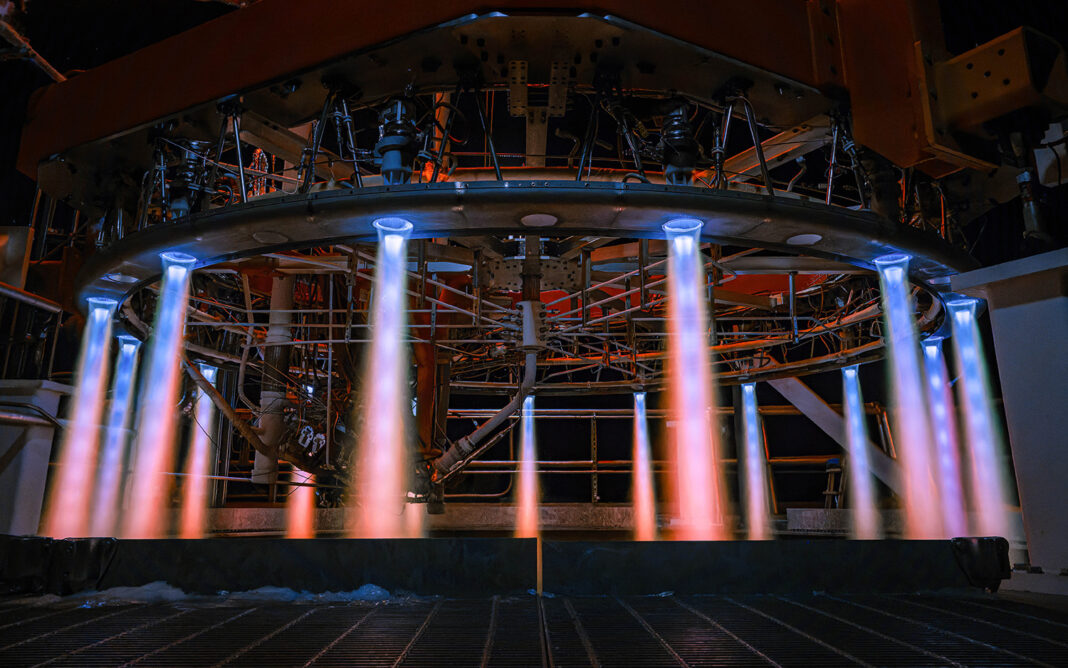

A recent communication from machine manufacturer Solukon sheds light on a space company that develops 100% reusable rockets. Named Stoke Space, the company headquartered in Kent, Washington joins the New Space era with the goal of delivering low-cost, on-demand access to and from any orbit.

To do so, it bets on AM to design and manufacture copper thrust chambers. Given their complex inner structures (regenerative cooling channels and built-in manifolds), it’s often difficult to achieve a reliable depowdering process of the 3D printed parts.

While the challenge is common to most space companies, the solutions they rely on differ from one to another. Stoke Space decided to rely on Solukon’s SFM-AT800-S, Solukon’s flagship product that was the first to benefit from the SPR-Pathfinder® Software.

Solukon explains that for complex geometries there’s another way to optimize depowdering even further – by analyzing the CAD file of the part. The unique Solukon depowdering software SPR-Pathfinder® does so: It works with a digital twin of the part and calculates the motion pattern for the Solukon system automatically to get the powder out of the complex structures. “SPR-Pathfinder® is a convenient tool to optimize the depowdering before it even started,” said Andreas Hartmann, CEO and CTO of Solukon.

With maximum dimensions of 600 x 600 x 600 mm (alternatively: 800 x 400 x 550) weighing up to 300 kg, this machine remains the most widely used automated powder removal system in Solukon’s portfolio.

The SFM-AT800-S uses targeted vibration and unlimited 2-axis rotation in a protected atmosphere to get unfused powder out of metal laser melted parts fully automatically, Solukon reminds.

“We chose Solukon for their industry leading capability in automating depowdering of complex parts,” said Zach Sander, Head of Engine and Fluid Systems at Stoke Space. “Regeneratively cooled rocket engine thrust chambers are notoriously difficult to depowder, and we wanted to ensure we had a robust machine to reliably depowder these difficult copper components.”

Featured image: Stoke Space. Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure you send it to contact@3dadept.com