Home =

Solukon - search results

If you're not happy with the results, please do another search

New dimensions of depowdering: The Solukon SFM-AT1500-S

In recent years, vertical industries such as aerospace, where high efficiency drives the way components are manufactured, have continuously pushed the boundaries of what is possible with Additive Manufacturing. At the same time, some 3D...

Rodhe & Schwarz deploys automated depowdering solution from Solukon

Rohde & Schwarz has been in the field of mechanical and electronic assemblies for the past 90 years. It has a production plant at Teisnach, Bavarian where its Additive Manufacturing division produces heat exchangers,...

Solukon to unveil enhanced depowdering system for 3D printed parts at Rapid+TCT 2024

Machine manufacturer Solukon has announced an improved version of the SFM-AT350/-E, its automated depowdering system unveiled last year at Formnext. As a reminder, this machine is an upgraded version of the SFM-AT350.

Since last year, the...

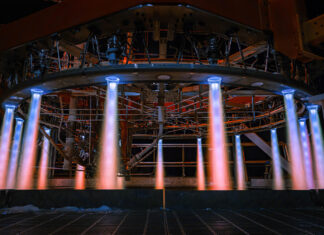

Stoke Space bets on Solukon to address depowdering challenge of 3D printed copper thrust chambers

A recent communication from machine manufacturer Solukon sheds light on a space company that develops 100% reusable rockets. Named Stoke Space, the company headquartered in Kent, Washington joins the New Space era with the...

M&H bets on a Solukon system for depowdering of metal 3D printed parts

M&H, a provider of design, 3D metal printing, surface treatment and finishing services, has added an automated depowdering system to its production environment. The Austrian company wanted to ensure the metal 3D printed parts...

BMW Group enhances SLS 3D printed parts production with Solukon’s SFP770 post-processing system

German automotive manufacturer BMW Group will improve its SLS 3D printed parts production facility with Solukon's SFP770 post-processing system. With a combined unpacking and cleaning station, this machine can accommodate build boxes from other...

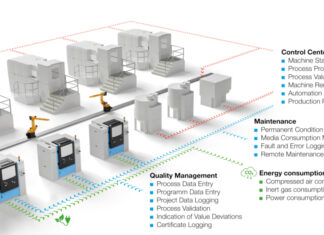

Solukon’s upgraded Digital-Factory-Tool can now measure the carbon footprint of depowdering

Germany-based automated depowdering company Solukon is enhancing its two-and-a-half-year-old Digital Factory Tool (DFT) with a carbon footprint measuring solution.

To fulfill its role in comprehensive quality monitoring and the digital integration of the machines, Solukon...

Solukon adds three key upgrades to its depowdering system for metal 3D printed parts

Two years ago, we caught up with Andreas Hartmann, CEO and CTO of Solukon to discuss the SFM-AT350, the company’s depowdering system for medium-sized metal 3D printed parts. Today, the company unveils an upgraded version...

Solukon and Rivelin to put forward automated solutions for the Additive Manufacturing industry at Formnext 2023

The German machine manufacturing company Solukon and British robotics technology company Rivelin have completed an R&D project regarding the applications of their products in easing the Additive Manufacturing process, and the results of this...

Solukon releases a powder collection unit that should be used after the depowdering of metal 3D printed parts

With every step that surrounds the depowdering process, machine manufacturer Solukon is uniquely positioned to address the challenges of the main steps that precede or follow the depowdering phase. One of these challenges consists...