Last week, machine manufacturer Solukon announced that its recently patented SFP770 postprocessing system can now accommodate build boxes from other 3D printers. This compatibility will expand the utilization of the machine across a wide range of industrial users – especially those using EOS machines.

As a reminder, in 2020, the expert in automated powder removal solutions launched the unpacking and cleaning station SFP770 for polymer 3D printed parts. The development of this system had been triggered by an automotive industry customer’s request that wanted to both unpack and clean polymer components automatically, without the user coming into contact with the plastic powder.

According to Solukon, this machine is the only one to include both an automated unpacking station and a cleaning station for SLS components in just one system. The compatibility with EOS machines – the P1 and P5 EOS printers especially – is made possible thanks to new adapters that enable the SFP770 to integrate their entire build boxes.

“We’ve received several requests for a postprocessing system, especially for the EOS P 500. Since the EOS P 500 is a standard plastic printer, our SFP770 postprocessing system paired with the correct adapter is now available to a much larger user base,” Andreas Hartmann, CEO & CTO of Solukon comments.

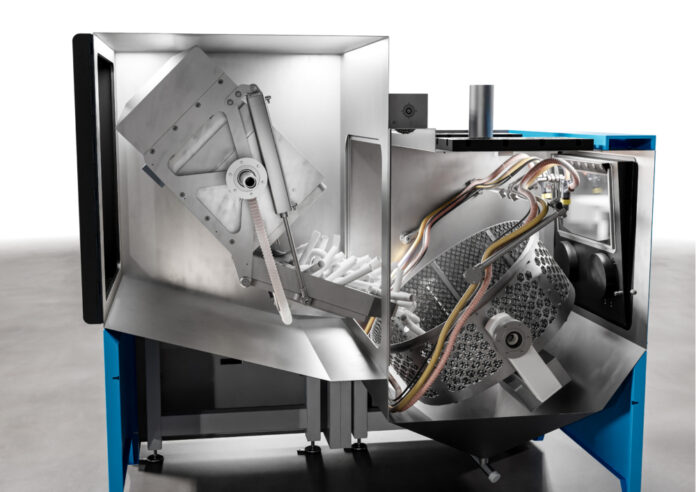

The process operation is undertaken in 4 main steps: loading, unpacking, transferring and cleaning.

Once a lift truck places the build box in the system, a vibrating sieve cover placed over the inserted build box, rotates based on an optional programmable process to remove the powder on the parts. The loose powder is extracted from the sieve cover directly and without contamination and conveyed to a recycling unit or storage silo (unpacking process). When this task is complete, the build box rotates towards the basket and opens the sieve cover.

The sieve cover now functions as a slide and the parts are slipped carefully into the basket. If necessary, the automatic transfer process can be paused to manually remove certain components that should not be cleaned automatically. After transfer, the system can immediately be loaded with a new build box, while the components from the first batch are cleaned in the second half of the system, the basket, a press release explains.

The cleaning part occurs when the basket rotates in the direction of the blasting unit and begins turning. Interestingly, rather than just separating glass beads from plastic powder using air separators or cyclones, the machine can optimize the preparation of the blast material (i.e., the glass beads) using ultrasonic sieves. Furthermore, the operator can program parameters, such as rotation angle, blast intensity, distance or basket rotation based on its intended goals.

“Because so many process parameters can be programmed, the SFP770 achieves the best cleaning results, independent of build material and without manual intermediate steps. Our system offers another advantage: parts of varying shapes and sizes can be cleaned simultaneously, which increases the flexibility and productivity of AM production,” says Hartmann.

Solukon’s machine capabilities have often been mostly highlighted in powder removal of metal 3D printed parts. The capabilities of the SFP770 could play a crucial role in helping industrials achieve series production with polymer 3D printing. Hopefully, the demand for automated unpacking and cleaning stations will lead to applications that will confirm what we already know for sure.

Remember, you can post jobopportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com