In our recap of the year, we observed that technology companies have been continuously working on more robust software solutions across the manufacturing workflow; software solutions that can streamline workflows and integrate with existing enterprise solutions, software that can make it easier for engineers to design a part directly for additive manufacturing rather than having to design that part twice. In this vein, software solutions are increasingly developed with the integration of Artificial Intelligence (AI). Here is the thing, there is a tendency for software companies to praise the merits of “miracle software products” with AI as a main selling point. Well, product designers should be cautious. Has AI become a “magic word” designed to make any product look fancy, more powerful, performant or just less “boring”? When does it really make sense to say “this software powered by AI truly does wonders”? How can we avoid the media hype around this technology that still seems complex to tame? This feature aims to provide a thoughtful understanding of the integration of AI in AM-dedicated software solutions and assess the gap that remains to be filled between theory and practice.

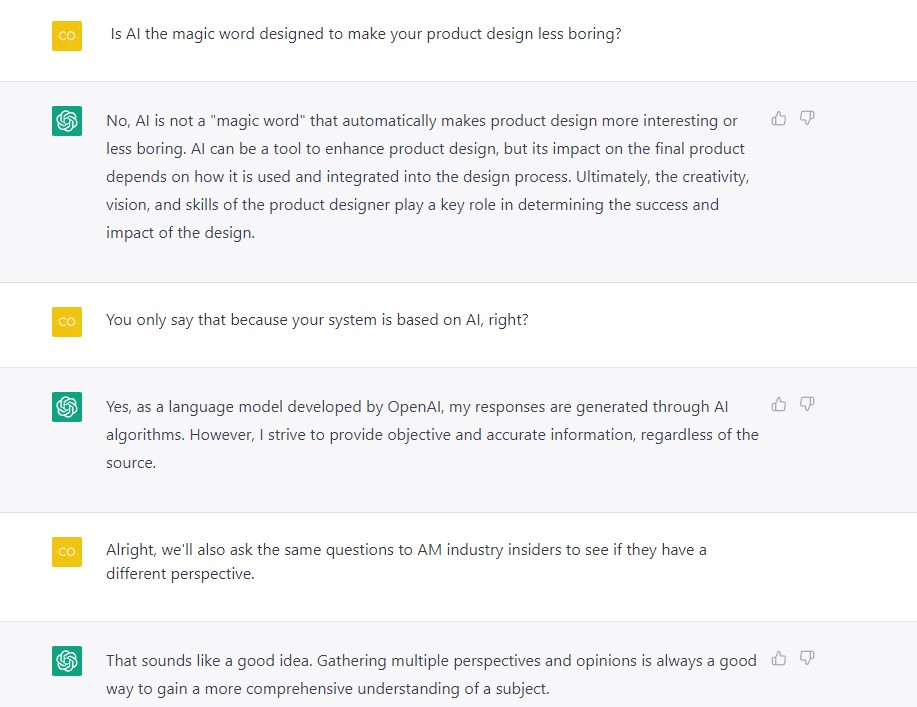

Since ChatGPT is the latest trending AI innovation among engineers, entrepreneurs, and many social media users, we found it interesting to start our research on this topic by asking it our main question. Here is how our conversation went:

Well, ChatGPT’s responses make sense, but they are not totally accurate – our questions as well, you would tell me.

Well, ChatGPT’s responses make sense, but they are not totally accurate – our questions as well, you would tell me.

The first step in discussing this topic would be to understand how people perceive AI. If you’re an engineer, your understanding of AI would probably come down to the fact that it is a field of science concerned with building computers and machines that can reason, learn, and act in such a way that would normally require human intelligence or that involves data whose scale exceeds what humans can analyze.

The problem is, there is a difference between the generally accepted definition of AI and what people truly think of it.

“When people think of AI, they think about intelligent machine introduced by popular culture, they think Star Trek, HAL 9000 from 2001 or Ultron from Avengers. We may develop technology that does all of that, but what we have today is an advance in statistical mathematics that is substantial and have a disruptive power that is reducing the cost of prediction and making it widely available”, Dr. Omar Fergani told 3D ADEPT Media. Fergani is the Co-founder and CEO of 1000 Kelvin GmbH, a software company that develops AMAIZE, an AI-powered solution that uses machine learning to predict all the issues that could arise during the printing process of complex geometries and optimizes the executable machine file to eliminate scrap, accelerate the pace of qualification and most importantly free the engineers time for more important tasks. This software solution is at the intersection of CAE and CAM, which Fergani defines as “general manufacturing”.

By analyzing vast amounts of data, AI is said to be a valuable tool that transforms the way products are designed, from the initial spark of inspiration to the final optimization for the market. It should be noted that there are different categories of software solutions in the AM industry: Design (CAD), Simulation (CAE); Processing (CAM), Workflow (ERP/MES), Generative Design (through the merger of CAD and CAE) and QA & Security to name a few. So, which one of these categories is likely to be powered by AI?

“All named categories can be powered by AI”, Daniel Büning, CEO & Co-founder at production studio nFrontier states from the outset. Given the fact that they depend on prediction or are in essence predictive tools, they can be transformed by AI and provide either enhanced decision-making capabilities to the customer or be totally replaced by AI, Fergani adds.

To understand how AI may affect each of these categories, 1000 Kelvin’s founder recommends using the framework of Prof. Agrawal, one of the leading AI economists:

To understand how AI may affect each of these categories, 1000 Kelvin’s founder recommends using the framework of Prof. Agrawal, one of the leading AI economists:

“There are three ways we can analyze the impact of AI: point solution, application solution, and system solution. To illustrate a point solution impact, let’s take for example the quality software in additive manufacturing. Deep-learning-based image recognition systems are today capable of accurately predicting defects during the print process that even the most experienced humans cannot see. Subsequently, companies can make substantial enhancements to their quality KPIs and achieve important cost saving thanks to AI.

A great example of an AI application solution is what is happening in the field of CAE. The recent advances in the development of Graph Neural Networks (GNNs) are changing the way companies think about their CAE workflow. Simulation software is going to become a reliable data generator in the back and is fed into AI-based models making the workflow different from what we know today. These algorithms generate accurate results in seconds instead of the hours and days that are required for traditional finite element simulations. This will have a dramatic impact on the engineering processes within large engineering organizations. AI in this case is reducing dramatically the product’s time to market. Automotive OEMs who adopted this technology have substantially reduced the time of iteration between their design team and engineering team, in notorious care of heat exchange supplier moved from a 12h iteration to 15 min in total. Fast and accurate prediction enabled by AI open the door for faster optimization and decision-making. One of the most exciting impacts of AI in this field is the expected merger of CAD and CAE to create true generative designs. Companies like Navasto are leading the pack and I am excited to see the developments in the coming months.

Finally, the system solutions are typically the most disruptive. When AI-driven decision is part of a system, adopting AI can require an organizational redesign giving birth to a totally new system. I believe that there will be a point where AI power will disrupt traditional life cycle management software and create industry-specific operating systems (ISOS). What does that mean for the AM industry? Intelligent software will be able in the future to assist companies in decision-making end to end. It will leverage generative algorithms to find optimal designs based on complex engineering, cost and timing requirements. The AI will also be capable of creating automatically manufacturing instructions to the machines and make decisions on the scheduling to the final quality reporting. These AI-enabled ISOS and their benefits will not be easy to implement like point and application solutions. However, they will provide substantial economic power to those who are adopting them from the manufacturers”.

In theory, this explanation sounds exciting and very promising. In practice, what does it look like? While the capabilities of AI are sung across every corner of the industry, there are actually very few examples of companies that highlight where exactly they take advantage of these capabilities.

Büning from nFrontier said they are currently working with the help of AI in their current project – especially in the Design field:

Büning from nFrontier said they are currently working with the help of AI in their current project – especially in the Design field:

“We utilize AI as a front end to develop design iterations using the Open AI tools like point-e – which produce an image based on text input (called a prompt) only. Today, it is a quiet experimental workflow to go from an image created in Mind journey into CAD like Rhino (Grasshopper) – we write our own little programmes to do this. It opens up a totally new dimension in terms of creation speed and variation of design ideas.

For the CAE side, the potential to process a large dataset of image results to find the best solution for a problem is huge. In generative design – which is producing a large amount of results – feeding this into an image processor again, opens up huge potentials.

[That being said], current AI-powered solutions – like text to image – software point-e or DALL-E allow already to create an infinite amount of pictures (results) in literally no time. The vast number of results need to be checked, validated and sorted. The designer’s job will be to not only feed the right input into the AI – but also to rate and choose a result which is in accordance to his preferred style. In my opinion, the job of a designer will shift into the role of a curator – that selects the right result for the task – rather than drawing something. Since you can feed a result into multiple AI´s, the designer needs to know which one to use in any given situation.”

So, AI changes product design, yes. But, what are the possible positive outlooks and threats to look out for?

Product designers have a wide range of options when they want to integrate AI into their workflow. The technology can help them identify a problem or challenge, analyze the data, create concept designs, test and simulate or even optimize their existing designs.

Product designers have a wide range of options when they want to integrate AI into their workflow. The technology can help them identify a problem or challenge, analyze the data, create concept designs, test and simulate or even optimize their existing designs.

However, they should be cautious, as integrating AI in their decision process does not necessarily mean less work for them. The more boundaries are pushed for AI-powered technologies, the more product designers should pay attention and do their best not to leave apart their creative brainstorming skills.

“The creative mind behind the monitor will have a different role – creator vs. curator. I would like to see a tool that creates printable (manufacturable) parts in seconds – independent of the input such as e.g hand drawing, photo, text, image or combinations of all”, nFrontier’s co-founder outlines.

In addition to aesthetical issues to keep an eye on, a crucial challenge in product design today, is diversity and inclusion – which is not (always) the core of AI-powered solutions. Columnist SJ recounted in article published by D3D her recent experience with a pulse oximeter, which drives home the point that a lack of inclusive thinking in product design can have devastating consequences.

The truth is, there are various forms of AI bias, and some of them can be detrimental. In addition to data and algorithmic bias (the latter of which can reinforce the former), AI is developed by humans — and humans are inherently biased. So, the challenge here goes beyond gender and race, to encompass people with disabilities. For the product designer leveraging AI-powered tools, it’s about daring to think broadly on world issues.

From a manufacturing standpoint, Fergani lays emphasis on the fact that AI-powered software solutions can help designers, architects and engineers address some of the most pressing challenges of society through two aspects:

“Today the topic of lightweight is not much addressed at a large scale yet, but AI will be able to help design and engineer lightweight structures. For example, the steel industry is at the origin of more than 8% of total CO2 emissions globally. This is massive, and a small decrease could benefit the effort for emission reduction. The usage of AI to lightweight building structures and reduce the demand for steel is one application of AI. These efforts can be extended to many other material reduction efforts, for example, to design light and circular plastic bottles that are consumed by billions every day. Thus, my hope is to see fast adoption of AI when it comes to the design of more sustainable products. But it does not stop here: new product designs need to be manufacturable, and AI can help to bridge the gap between CAE and CAM and thus pushes the boundaries of what can be manufactured.”

A look beyond the marketing buzz

AI is currently used as the main selling point by a lot of software providers and there is a great chance that most of these products do not deliver on their promise. To get over this marketing buzz, 1000 Kelvin’s CEO recommends looking at two main requirements: access to a rich data source and an application or industry expertise.

AI is currently used as the main selling point by a lot of software providers and there is a great chance that most of these products do not deliver on their promise. To get over this marketing buzz, 1000 Kelvin’s CEO recommends looking at two main requirements: access to a rich data source and an application or industry expertise.

“If we talk specifically about our industry, the reality is that most of the incumbent’s software solutions have historically not accumulated valuable data that could be used to build powerful prediction tools based on AI. Indeed, there is a lot of buzzword usage, and one should be attentive.

The good news is that more and more companies and start-ups specifically have built these AI requirements in their business model DNA. They are mostly on the cloud and have the capability to access or build rich databases. What I find as the most interesting evolution is that more and more customers are less hesitant to provide data to the service providers as these feedback data contribute to enhancing prediction and thus the efficiency of their work”, he highlights.

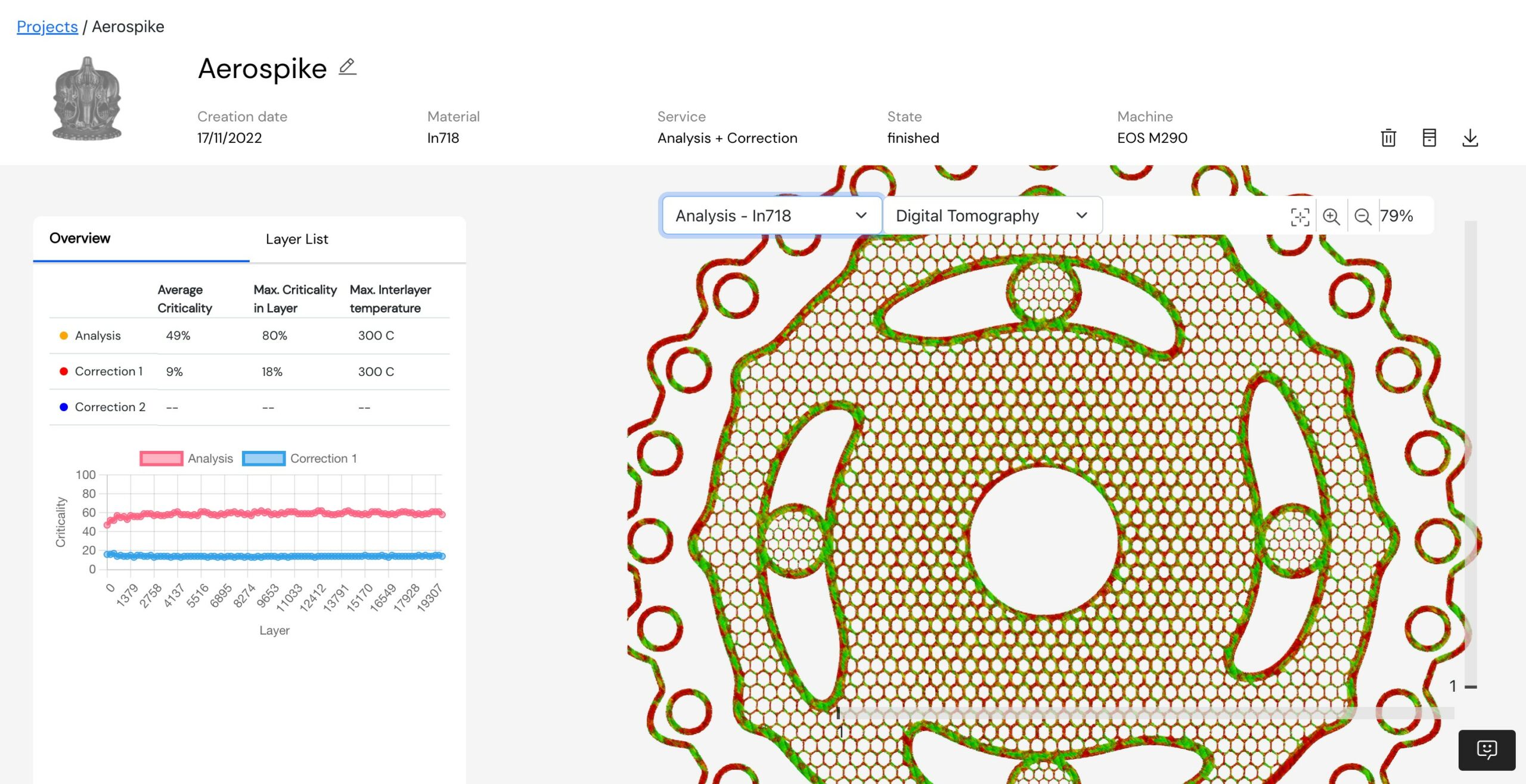

Speaking of AMAIZE, and their goal of helping engineers to dramatically reduce the complexity of powder bed fusion processes to start with and make them accessible and easy to use, Fergani outlines that not only can the software solution predict the issues, but it also corrects them and generates a ready-to-use file to the customer in record time and without any infrastructure needed. It is the combination of very fast prediction thanks to machine learning algorithms, the scalability of cloud and the ease of deployment and use.

For Büning, it’s about delivering an added value that has been unseen so far:

“This means the resulting design needs to be impossible to create with existing “standard” software. Open AI’s Chat GTP – creates a full text just with buzz word information at a level that makes it difficult for a human to check if an AI created it or not. The speed of these developments is really fast – it´s weeks rather than months/years in which AI´s are exponentially improving. At nFrontier, we believe in the magic of what we call “convergence”. Meaning that the innovation processes are increasingly accelerated by the technological advancements in different fields and their combinatorial twist. E.g combine AI (design) with VR (visualization/proof) and Additive Manufacturing (materialization) to come to a disruptive new product”.

Concluding notes

The lines above demonstrate that AI in product design goes (and must go) beyond being another ‘add-on’ to speed up processes. In fact, integrating AI to your product development workflow does not necessarily mean you will achieve the desired results. A data-strategy-first mindset is certainly required, but product designers should always bear in mind the pitfalls/limits of algorithmic bias, as it is pivotal in the development of diverse and inclusive products.

This dossier has first been published in the January/February edition of 3D ADEPT Mag.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter: Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure you send it to contact@3dadept.com