Last year, Kongsberg Ferrotech, Equinor, SINTEF, and Gassco joined forces to develop 3D printing technologies for subsea equipment repair and maintenance. The partners who respectively specialize in robotics, energy, research and gas, believe that AM for lifetime extension of subsea assets, can have great financial and environmental benefits for installed as well as future subsea assets. The robotized 3D printing project contributes this way to the energy transition and is supported by the Research Council of Norway.

So far, the team has identified several applications such as repair of cracks, dents, and replacement of lost materials where AM could play a crucial role compared to traditional manufacturing processes. The aim of the team is to be able to leverage metal AM in-situ for the repair of metal parts. They are currently looking to qualify AM for the repair of cracks and dents.

The project has been well received within the industry, and has raised the interest of another energy company, Shell, that has decided to join the consortium.

“We’re happy to be part of an exciting development. When we discovered this joint industry project, we realized that the repair methods have many applications within Shell’s global operations. The technology is of great interest to Shell and fits nicely into our portfolio of advanced technology for subsea robotics and 3D printing. We are looking forward to a close collaboration with our industry partners”, says Angeline Goh, 3D Printing Technology Manager at Shell.

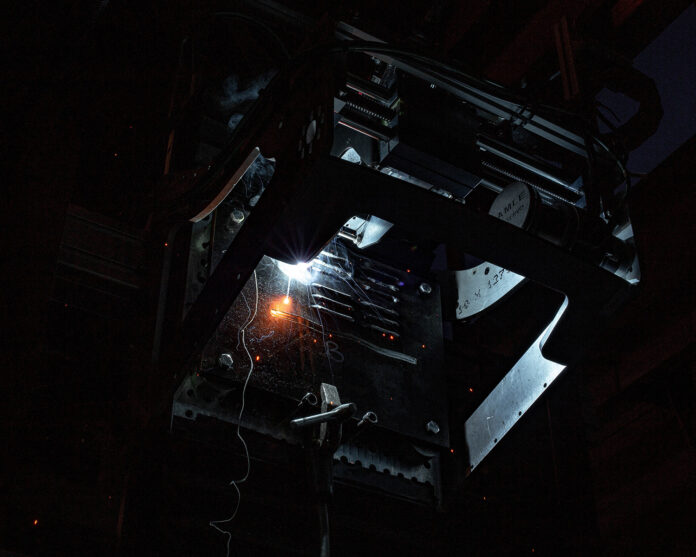

AM will be integrated in Kongsberg Ferrotech’s Inspection, Repair and Maintenance (IMR) robots. In the repair process, a dry environment is created to offer documented high-quality repairs without disrupting ongoing operations.

“We’re excited to welcome Shell to the team and consider their decision as an important recognition of the potential represented by our technology. With another global partner onboard, we’re able to adapt our technology towards a large global market. Together with our partners we’re now preparing for the world’s first test of 3D printing repairs in demanding ocean spaces, says Torgeir Bræin, CTO at Kongsberg Ferrotech.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure you send it to contact@3dadept.com