Service and maintenance based on subsea 3D printing solution could be provided as early as 2022

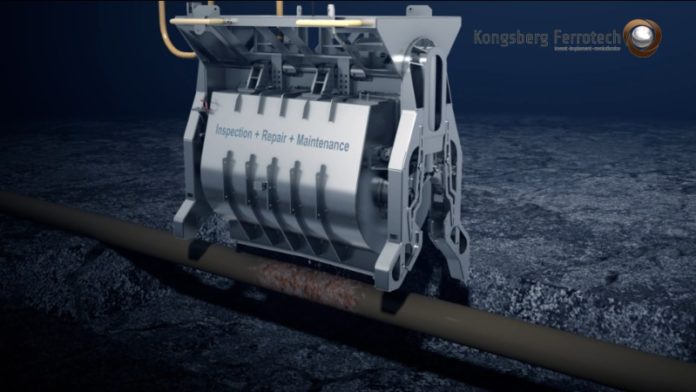

Something interesting is happening in the energy industry right now, as several developments are being discussed to tap natural resources and address global climate challenges. The latest project to date has been launched by Kongsberg Ferrotech, a Norwegian robotics company, that designs and manufactures game changing subsea robots for the oil and gas industry.

The company has decided to join forces with energy company Equinor, independent technology research institute SINTEF, and gas company Gassco to develop 3D printing technologies for subsea equipment repair and maintenance.

Backed by the Research Council of Norway, the teams of these companies will work under the PETROMAKS 2 program and develop a robotic metal AM technology that will rebuild damaged metal structures – layer by layer – allowing permanent repairs and implementing new functionality where needed.

Accroding to Kongsberg Ferrotech, the project will allow for in-situ repairs of subsea components like flowlines and conductors,– significantly extending the lifetime of the assets. Lifetime extension is of high importance for sustainable development and optimal utilization of resources, both in Norway and globally.

“The rapid development of 3D printing technology is creating new opportunities and markets going forward,” says Brede Lærum, head of 3D printing at Equinor. “Combining this technology with Kongsberg Ferrotech’s robots opens many exciting new possibilities for subsea repairs and modifications. We are looking forward to a close collaboration with our industry partners.”

“This is the start of a new industrial adventure that is of strategic importance to our company. We see a large long-term market opportunity also beyond the oil and gas industry,” says Christopher Carlsen, CEO at Kongsberg Ferrotech.

Inspection, maintenance, and repair (IMR) robots are pivotal to the success of this project as they can achieve repairs and modifications in a dry environment while completely submerged. So far, the teams have already completed deepwater testing on the composite repair in the Trondheim Fjord in Norway.

Kongsberg Ferrotech announces that we might expect further deployments of the technology as well as commercial applications and operations in the Southeast Asian market in Q3 2021. “We plan to offer service and maintenance based on 3D printing as early as 2022”, Carlsen notes.

For those who do not know, the global market for underwater repair is a very broad one. Only in Norway, the shelf alone has over 10,000 kilometers of subsea pipelines and given the time-consuming, expensive and unexpected production shutdown, there is a demand for new solutions for underwater pipe repairs and lifetime extension.

Two years ago, when GXN innovation suggested that mobile 3D Printing drones could be used under water to repair cracks of the earth. The idea raised a lot of interest but no feedback was shared regarding this project. Today is different, there is a strategic roadmap that has been well defined and I want to believe that its successful development and implementation might disrupt the market of maintenance and repair of subsea components.

Remember, you can post free of charge job opportunities in the AM Industry on 3D ADEPT Media or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com