From lightweight carbon fibre elements to topologically optimised concrete floor slabs, SAEKI will focus on large scale applications across industries

Another newcomer showed up on our radar this morning: SAEKI, a Switzerland-based company that secured a $2.3M seed funding round to emerge from stealth mode. The funding round was led by Wingman Ventures including participation from Vento Ventures, Getty Capital and angel investors.

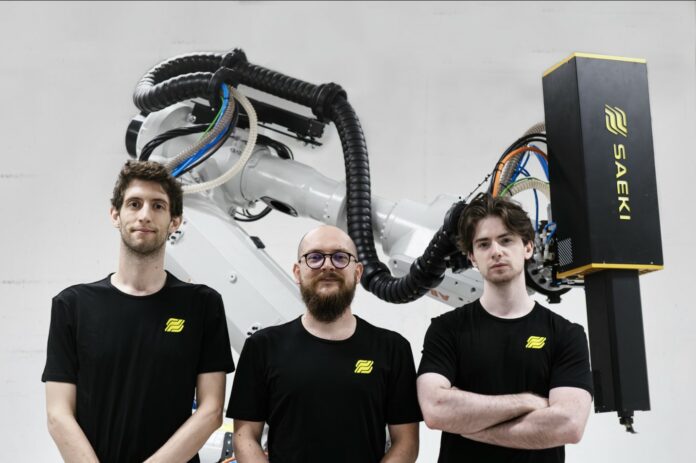

Founded in 2021 by Andrea Perissinotto, Oliver Harley and Matthias Leschok, SAEKI works with the architectural design, engineering design and construction services industry to turn complex designs into reality, save concrete and CO2 having developed a new method to produce custom concrete formwork cost-effectively.

To do so, they combine 3D printing, milling, with large industrial robots that can print formwork up to many metres in length. A number of companies already develop automated factories in the industry, but SAEKI is one of the few that aims to target both the construction and other industrial sectors.

Andrea Perissinotto, Co-Founder of SAEKI, commented: “From what we build underground, to what we build on earth, to what goes to space, from the construction to aerospace industries, there is a need for large, one-off (custom) components, that are mostly used once a couple of times at most, then scrapped. Manufacturing these parts, from the moulds to make concrete elements to the tooling required to build composite rockets, is labour intensive, has long lead times, and is very expensive. Moreover, these factors delay hardware iteration to get to the final product.”

The company is now building its first production hub, which will be the blueprint for further expansion. The production hub will offer industrial robots built by SAEKI. The robots will combine multiple digital manufacturing methods, from 3D printing, milling, inspection to creating an all in one low waste production process and recyclable materials. The robots will act as microfactories; self-contained units able to do all the manufacturing steps, easily deployable for localised manufacturing. Additionally, SAEKI will offer a quoting platform tailored to the customers’ own business needs to remove the complex opaque approach currently in the market.

The team currently works hand-in-hand with customers, understanding their unique challenges, and tailoring the microfactories to address their specific needs. This collaborative approach will help the business unleash its full potential.

Remember, you can post free of charge job opportunities in the AM Industry on 3D ADEPT Media or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com