Carnegie Mellon University employs Optomec’s Aerosol Jet Technology to extend 3D micro-additive manufacturing methods for fully printed conformal sensors, low loss passives and antennas for on-chip and off-chip electronics.

Dr. Rahul Panat, who led the laboratory of research of the university aims at finding solutions in the areas of printed and flexible microelectronics manufacturing and lithium-ion batteries. These areas are crucial to realize devices and systems for wearable and Internet of Things (IoT) applications.

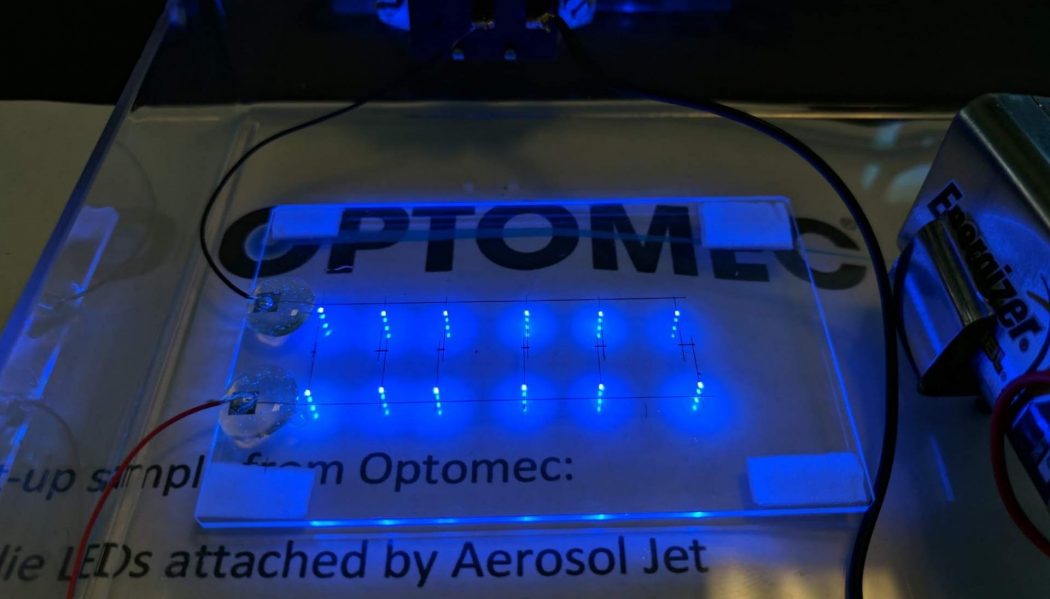

They used Optomec Aerosol Jet 3D print system to directly print nanoparticle inks and polymers over complex surfaces. “The Aerosol Jet system has enabled us to fully print 3D antennas at the sub 100um length scale and to conduct simulation studies to identify omnidirectional antenna designs. These fabrication methods are unique and can pave the way for several applications in the high-speed communication areas”, said Dr. Rajul Panat.

Furthermore, according to the team of researchers, complex 3D battery architectures manufactured using Aerosol Jet demonstrate electrode utilization and fast-charge discharge cycles. Dr. Panat and his team are focused on developing next generation fully printed and in-situ cured solutions that have practical use within mainstream manufacturing.

For further information about 3D Printing, follow us on our social networks and subscribe to our newsletter!

//pagead2.googlesyndication.com/pagead/js/adsbygoogle.js

(adsbygoogle = window.adsbygoogle || []).push({});