Pirevo, an Austria-based 3D printing solutions provider, has extended its portfolio of Additive Manufacturing technologies & services. Following its successful move in their factory based at Ried im Traunkreis, a municipality in the Kirchdorf district, the company now acts as a one-stop shop which covers the entire digital value chain, from the first idea to the final finishing.

From the idea to the digital model

The range of services starts with a well-founded consultation right from the first idea. Depending on the planned project, the company provides support with the digital design of new products, with the data preparation of existing models or the identification of components suitable for additive manufacturing. In addition, reverse engineering options such as 3D scanning for digitising existing objects are offered.

Huge selection of materials

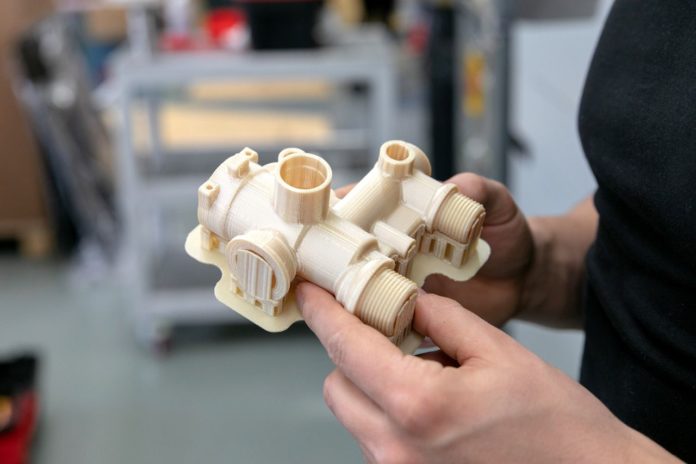

Once the digital data is available, the Prirevo team provides expert advice on the best materials. For this, customers have a vast range of materials available in stock, ranging from biodegradable plastics and high-performance polymers to silicone-like materials. For example, objects can be manufactured from materials filled with carbon fibre, TPUs in various Shore hardnesses, or ESD materials for electrical components.

Digital manufacturing

The company also offers different shaping and subtractive manufacturing processes for physical material processing, such as deep drawing and CO2 laser cutting. In addition, various additive manufacturing processes, including 3D printing processes such as FDM, SLA, LFS and SLS, are available and allow the creation of objects of any shape and size to meet all requirements.

Post-processing

For the post-processing of the objects created, customers can choose from a wide range of finishing options. In addition to various surface refinements, grinding, and painting activities, industrial ovens with a wide range of tempering options are also available. The pressing in of threaded inserts and the pre-assembly of assemblies can also be done on-site if required.

24/7 service and an express option

Since it sometimes has to be quick, the Prirevo team is available around the clock, seven days a week, and offers express production on request. With this offer, even short-term orders can be processed quickly and easily. The new service portfolio helps companies of all sizes produce custom-made products, series of all sizes, and to compensate for under-capacities in-house. The services are also increasingly requested for test productions to evaluate various digital production forms and materials for later implementation in-house.

Technology implementation support

In contrast to many other service providers, Prirevo pays particular attention to valuable technology and knowledge transfer to avoid customer dependency. For this purpose, the Prirevo team has set up an innovation centre, which, with the help of its in-house academy, offers a wide range of training opportunities in digital production on customer site, in-house or as an online course. Due to Prirevo’s manufacturer independence, customers can always get the best, brand-independent solution. After a successful implementation in-house, Prirevo continues to be available at any time with exemplary after-sales service, including reliable on-site support for machine service and maintenance.

Despite the expanded service portfolio, Prirevo remains true to its successful concept and continues to strictly focus on quality, user benefits, and on-site service. Many satisfied customers have relied on these qualities for years and have already had more than 8,000 components produced by Prirevo this year.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com