Friday 19.11. Last day of formnext. I am walking through the aisles, trying to greet as much people as I can – at least, those who are still on the show. I stopped by Oqton’s booth, to meet a smart guy I first “e-met” through the launch of Addm.io. While making 3D printing accessible through education is still a topic close to his heart, he is currently mainly doing so with a key focus on software – by helping organizations address their manufacturing challenges with an AI driven factory operating system as part of the brilliant team of Oqton. His name? Robin Huizing.

From one topic to another – or let’s say from an informal talk to a very serious one -, our conversation led me to dive more into what Oqton provides to the AM ecosystem. If you are a regular reader of 3D ADEPT Media, you probably know that Oqton is a (soon-to-be) 3D Systems company. If you are addicted to 3D ADEPT Mag, you may certainly have read Dr. Ben Schrauwen (the company’s CEO and founder)’s standpoint on “software automation in AM” (PP 26-30). If Oqton still does not look familiar, let me clarify it now:

The Belgian SaaS company was founded four years ago. It develops an agnostic cloud-based manufacturing operating system, which automates the end-to-end workflow across & beyond the production floor.

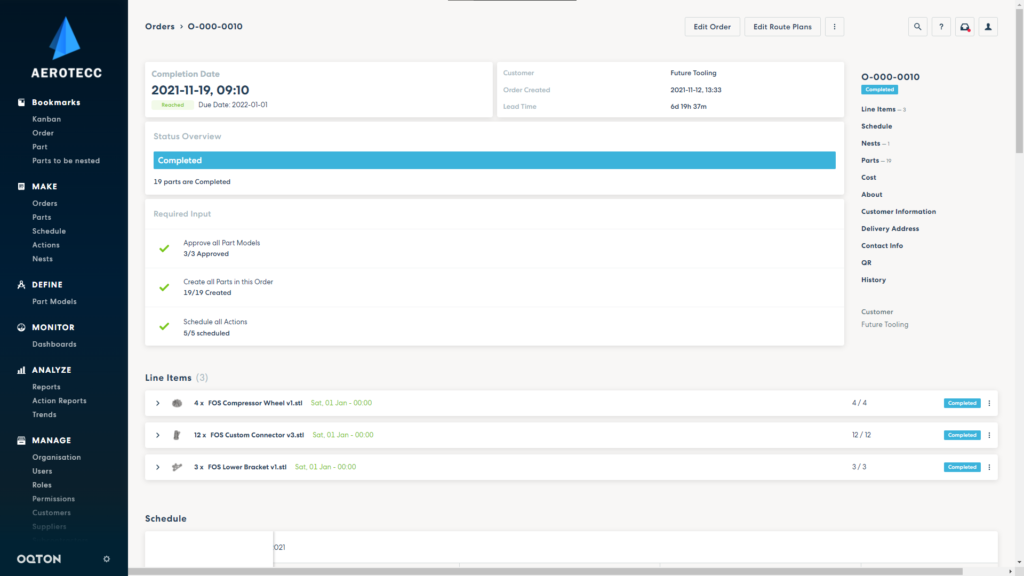

Well, one thing that was clear from my conversation with Huizing is that AM operations are complex to manage because of the numerous processes that are closely intertwined. From the moment an order is placed, engineering teams need to ensure several other stages go well. These stages include but are not limited to the build preparation, the manufacturing process, the post-processing stage, time and costs as well as the supply chain.

So, how does Oqton ensure all of that?

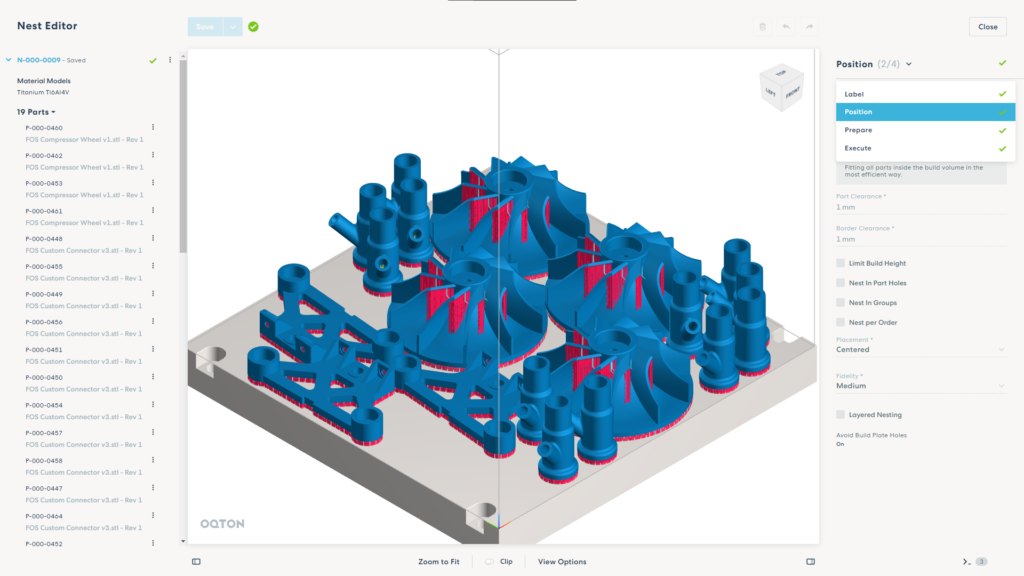

By relying on a cloud-based platform that can be extendable and customized for every user. The AI-powered solution, mainly known as a cloud-based Manufacturing Operating System (MOS) platform, directly integrates with production systems through IoT solutions. Being able to ensure quoting and pricing, inspection and identification services, topology optimization and more within the same platform requires a very large database that can integrate all data related to the manufacturing process.

Thanks to machine learning techniques, Oqton “automates various processes of manufacturing by providing users real time, traceability analyses”, Huizing said.

The platform portfolio now includes 3D Systems’ 3DXpert® which makes it even powerful for advanced applications. Not to mention the wide range of possibilities that result from the integration of 3D Sprint®, its Geomagic® portfolio and Additive Works”, he adds.

The latest version of 3DXpert® (3DXpert® 17) for example, is ideal for any engineer who wants to ramp up production with topology optimization and AI. Within the Oqton platform, the new version would speed up part design with higher yield and faster print times.

Indeed, thanks to machine learning-based classification, it is possible for users to easily and automatically identify the part types and allocate required preparations. This version of 3D Systems’ software also utilizes Hexagon’s HxGN Emendate engine to help engineers minimize part weight without jeopardizing functional performance.

On the other hand, as Additive Works’ Amphyon™ is acknowledged for its simulation capabilities, operators can achieve a physical simulation of actual thermal conditions inside the build chamber before printing.

From digital to real-life

I don’t know if engineers feel the same…but as an editor, there is a weird feeling of pride that consumes me every time I see and touch a print edition of 3D ADEPT Mag, after working on screens with my colleagues for months. I believe, this feeling might be the same for engineers who finally get to see real manufactured parts after working on them and seeing them on screens for a long time.

Well, at the end of my conversation with Huizing, my eyes fell out on a beautiful metal 3D printed part that was on the table. Seeing this part makes Oqton’s capabilities more tangible as Huizing explains that a closer look reveals three layers of part embedded in the complex print job.

Of course, there is certainly more than that…Engineers would have probably asked records of all statistics for each layer, or any topology optimization information, but I myself was too busy admiring the beauty of it.

Last but not least, we used to categorize software platforms to make it easier to understand their capabilities. These categories often include Design (CAD), Simulation (CAE); Processing (CAM), Workflow (ERP/MES), and QA & Security to name a few. In this case, I believe we should create a new category for Oqton’s platform as it does it all.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com