‘‘4D_Additive enables a 3D printing process, i.e. the inspection, repair and preparation of models in accordance with the CAD engineering standard which has long been established for other common production processes”.

Three months ago, CoreTechnologie announced the release of a new version of 4D_Additive, its 3D printing software.

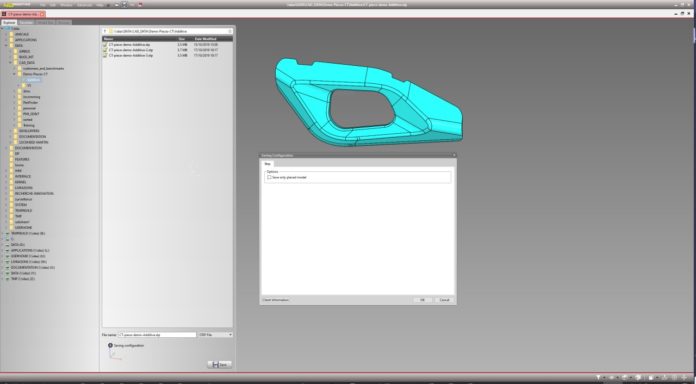

The official launch of the new version reveals new functionalities such as the use of exact B-REP CAD data of all common native and standard formats for the preparation of 3D printing jobs as well as the ability to generate repaired and optimized STEP models. A release that follows the recent collaboration the company signed with Substance.

What it means for users…

Accuracy in the repair of models can be arduous to achieve especially in 3D printing because triangulated STL models are still widely used by engineers. The only thing is that, these models do not provide a real CAD geometry.

With the new version of 4D_Additive, users can import exact models as STEP as well as other common native formats such as CATIA, NX, CREO and Solidworks to obtain the required precision for the repair of models. Most importantly, by using modelling functions with the B-Rep core of the software, these models can be adjust for 3D Printing.

The main benefit for this new capability is that the user will save more memory space for his data. Can you imagine hundreds of parts stored in a compact file size?

“Automated part alignment and intelligent nesting functions with multi-processor calculation enable reliable and fast filling and optimum use of the build space, for all common machine types. Special analysis functions ensure collision safety, optimum heat distribution and production-oriented component design and complete the software in terms of a seamless additive manufacturing process”, the company concludes in a press release.

Remember, you can post AM job opportunities for free on 3D ADEPT Media or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter: Facebook, Twitter, LinkedIn & Instagram! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com