6K Additive, the AM division of 6K that produces engineered materials and lithium-ion batteries enters a strategic partnership with Incodema3D, a supplier of metal AM technologies for aerospace, defense, and other industrial applications.

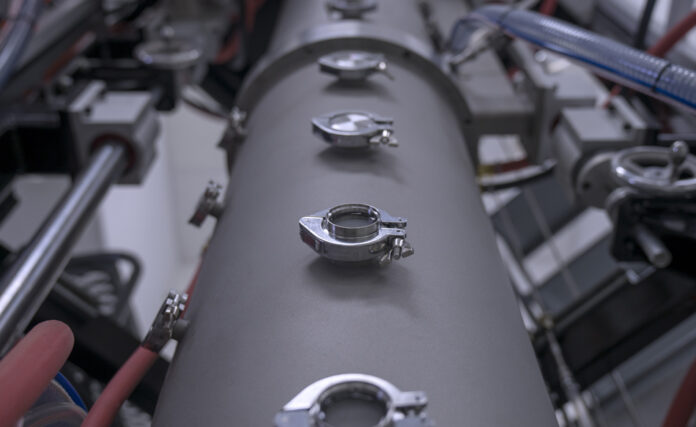

The partnership focuses on AM powder supply agreement and recycling. Incodema3D sought to secure a domestic AM metals powder supply that met strict quality standards and a solution for recycling their used powder and parts. By leveraging its UniMelt plasma microwave powder production system, 6K Additive can provide high volumes of domestically manufactured powder and a route to sustainably recycle Incodema3D’s used metals through its Powder Buy Back program.

Be it through partnerships or LCA projects , 6K Additive is one of the material producers that are investing efforts to advance its sustainability journey. As part of this project, Incodema3D sought to secure a domestic AM metals powder supply that met strict quality standards and a solution for recycling their used powder and parts. 6K Additive, through its UniMelt plasma microwave powder production system, is able to provide high volumes of domestically manufactured powder and a route to sustainably recycle Incodema3D’s used metals through its Powder Buy Back program.

Incodema3D director of additive manufacturing and metrology operations, Kevin Engel explains: “We are talking to clients now about projects for 2023 that will require ten tons of metal powder per month. When you’re going through that volume of powder, recycling becomes imperative, and sustainability is key to our business. By recycling our used powder with 6K Additive we have been able to drive down our contribution costs for material by 15% already. Add to it the quality standards both Incodema3D and our customers demand sets a high bar for any one supplier. 6K Additive overachieved on this front.”

Incodema3D undertook its own pre-qualification of 6K Additive’s nickel alloy 625 (Ni625), a high-strength and corrosion-resistant alloy, popular with many of their customer’s applications. Internal qualification samples measured tensile strength, microstructure, density, and chemical composition and benchmarked the results against existing suppliers and their strategic customer’s requirements.

6K Additive’s Ni625 surpassed every measure used in the assessment, including tensile strength (greater than 125 ksi), yield strength (greater than 85 ksi), and elongation at break (greater than 30%). “We tested five samples and each one returned density results of 99.9%, which far exceeds the minimum requirement. Anything over 99.5% density in additive manufacturing is a good part,” continued Engel.

In addition to Ni625, 6K Additive produces a full suite of AM powders including Ni718, low oxygen (500-700ppm) Ti64, stainless steel 316/17-4, copper 18150 and GRCOP, refractory powders including tungsten, tantalum, and rhenium.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure you send it to contact@3dadept.com