Alternative meat is currently trendy in the 3D printing industry as people are increasingly aware of the ethical and environmental issues surrounding conventional animal husbandry. So far, Redefine Meat is one of the rare companies that we saw addressing these issues – if one does not count Legendary Vish that is addressing a similar issue for fish.

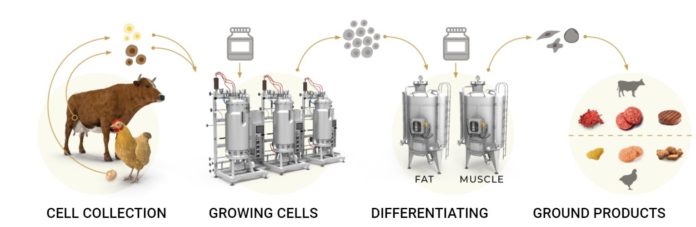

Today, we are going to add MeaTech 3D Ltd. to this list, another Israel-based company that is committed to developing premium cultivated meat. As the company notes, global protein consumption especially of meat and meat products continues to rise and to address its environmental, health, financial and ethical problems, the company has been developing an industrial cultured meat production process with integrated 3D printing technology.

To achieve this ambitious goal, MeaTech 3D Ltd, which is also the first cell-cultured meat company to be publicly listed, has recently secured US$7 million funding round, out of which it used US$1.19 million to acquire Peace of Meat, a Belgian start-up known for its stem-cell-based technology. The latter being able to manufacture “cruelty-free avian fats” including duck, goose and chicken fats, as well as cultured liver.

Following this acquisition, 3D bioprinted cultivated meat developer now ambitions to launch a pilot plant to manufacture cultured chicken fat in Belgium by 2022.

“The goal is to have that facility be something that can leverage commercial attraction by the end of next year. It’s certainly something that should take us beyond internal use and engage us with the outside world in a commercially viable way. If the pilot facility has the capacity, then the aim is to have industry collaborations that allow our ingredients to be accessible, testable and perhaps developed for specific counterparties or partnerships”, Simon Fried, (co-founder of Nano Dimension) Business Development Executive at MeaTech told our colleagues from FoodIngredientsFirst.

While the initial strategy for this Belgium-based plant will be to 3D print cultured chicken fat, MeaTech’s end-goal will be to use 3D bioprinting to fabricate real meat cuts, like chicken breast and steak.

“We believe that our cultured fat is an extremely promising additive ingredient that can potentially improve the taste, texture, and mouthfeel of plant-based alternative meats, which we believe can further drive market growth,” Sharon Fima, CEO of MeaTech said in a press release.

“A key challenge facing the cultured meat industry is cost-efficient production. We believe that establishing this pilot plant facility and scaling up our cellular agriculture technologies will be a significant step forward toward achieving cost parity with conventional meat as well as realizing MeaTech’s vision for the ‘Factory of the Future’ – comprising the inputs, processes and equipment underlying a flexible cultured meat manufacturing facility.”

Remember, you can post free of charge job opportunities in the AM Industry on 3D ADEPT Media or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com