LEAP 71, a company that develops complex software models for engineering, has released an open-source software framework named PicoGK.

Designed to provide engineers with foundational computational engineering capabilities that will allow them to build out their own modules, the software framework forms the basis for all of the company’s computational engineering models, including its proprietary RP/CEM model. As a reminder, the RP/CEM model is currently leveraged by The Exploration Company to generate production-ready parts for rocket and orbital engines.

According to LEAP 71, computational engineering’s impact is often compared to the introduction of Generative AI in other fields. Unlike laborious human-driven design of technical products, which can often take weeks and months, computational engineering generates parts, structures, and entire machines in minutes. Such parts can after that be produced by digital manufacturing techniques, such as industrial 3D printing.

Lin Kayser, Co-founder of LEAP 71, an innovator that you previously discovered through Hyperganic says : “Humanity is entering a critical phase, where we need to out-innovate some of our global challenges. Accelerating the speed at which new technologies can be invented and brought to market is paramount. This needs to happen broadly and cannot be done by just one company. PicoGK is one important step on the path to global adoption of this paradigm.”

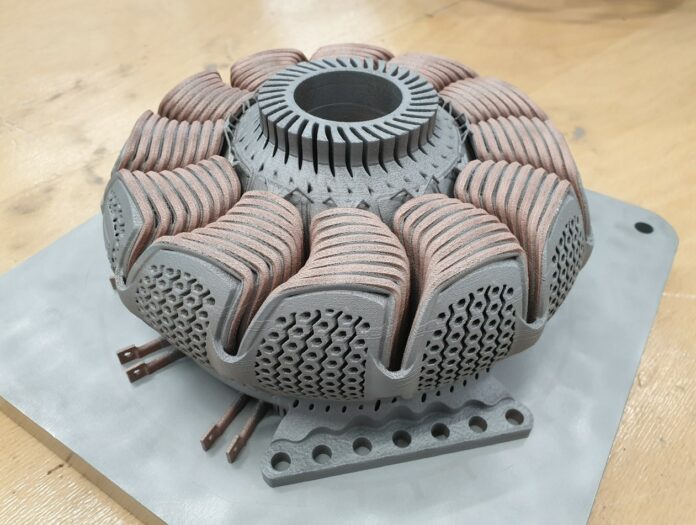

I believe LEAP 71’s computational engineering models can highlight the capabilities of certain AM processes like multi-material 3D printing. In a recent LinkedIn post that almost went viral, an electric Radial Flux Motor prototype was designed explicitly for multi-material AM using the company’s computational engineering technology. Timo Schröder, who first shared the picture, explained that “traditionally, the shape and topology of electric machines are very much limited by their assembly sequence. With [a] unique multi-material manufacturing process, developed by Fraunhofer IGCV in collaboration with SLM Solutions it will become possible to design and produce more complex, integrated, and intertwined stator/coil assemblies.” The part itself has a diameter of 220 mm, and was printed on an SLM Solutions SLM 280 HL machine, equipped with Fraunhofer IGCV’s proprietary multi-material powder deposition solution.

By releasing PicoGK today, Dubai-based LEAP 71 follows the example of other United Arab Emirates entities, which have opened their AI models for free to the public for both non-commercial and commercial use, a press release states.

Josefine Lissner, Founder and CEO of LEAP 71 said: “At our company, we are creating sophisticated machinery using Computational Engineering, in fields from electric mobility to space propulsion; from hydraulic systems, to heat exchangers. But Computational Engineering needs to become a global movement, and any movement needs to be rooted in Free and Open-Source Software.”

The technology is available immediately under the Apache 2.0 Open-Source License on LEAP 71’s Github repository.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure you send it to contact@3dadept.com