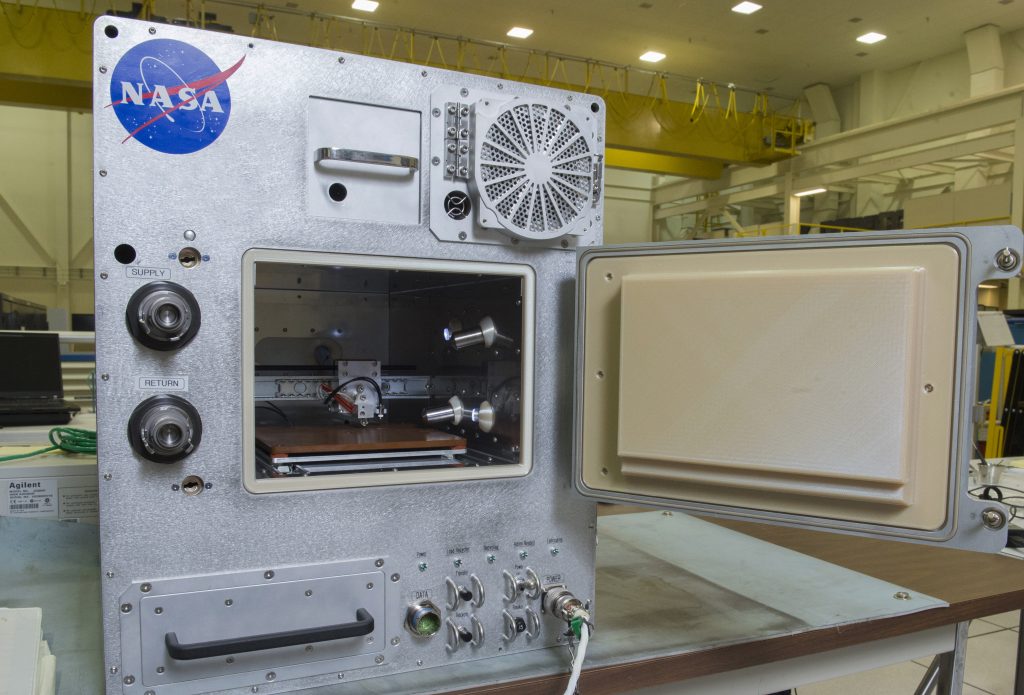

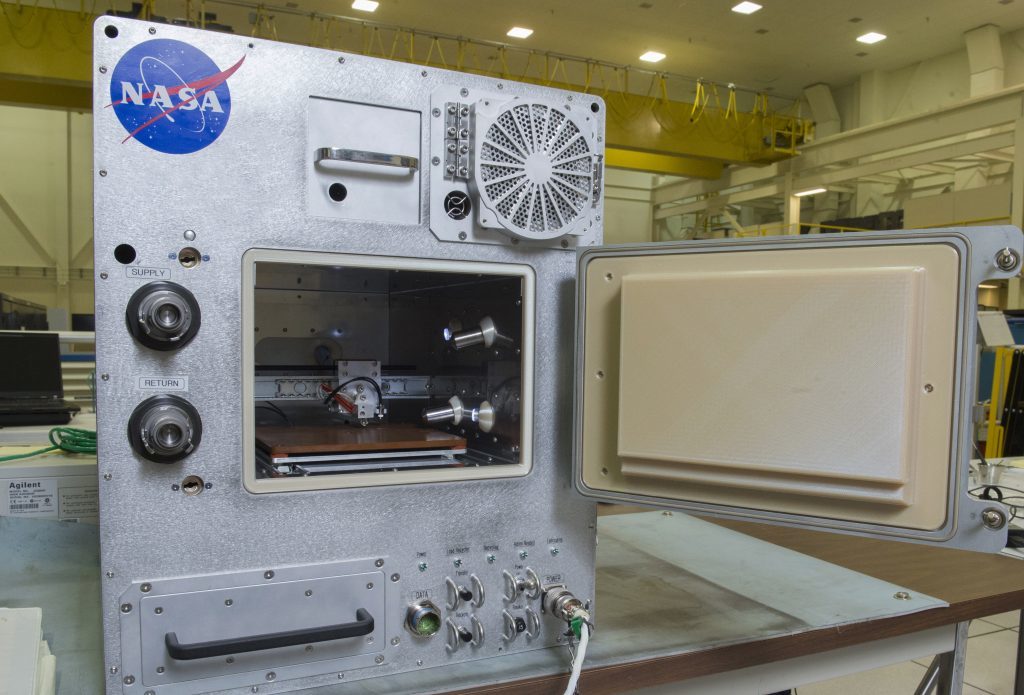

NASA has recently installed a 3D printer on the International Space Station (ISS). Called the Refabricator, the 3D printer is able to recycle polymer plastic numerous times to make new items.

NASA has demonstrated a thousand ways how much they value the potential of 3D printing: be it by running competitions, by releasing 3D printable files or in a mission.

Anyway, as far as the Refabricator is concerned, the 3D printer is handled and controlled on Earth by technicians that follow its manufacturing process through video cameras.

Niki Werkheiser, NASA’s In-Space Manufacturing Manager at Marshall Space Flight Center, in Huntsville, Alabama says: “Recyclers on Earth grind plastic pellets to create their products. But that grinding creates material sheer which prevents you from reusing that plastic again – it’s no longer strong enough. For this technology demonstration, the company Tethers Unlimited developed a novel recycling process that doesn’t require grinding – and that allows us to recycle the plastic multiple times.”

The importance of reusing plastic in space

In space, astronauts do not have a wide range of options as on Earth when it comes to manufacturing of parts. That’s why, reusing plastic would not only be useful but also essential for long-term space exploration.

Werkheiser explains that “we can replace a lot of the things we need when we’re orbiting above Earth; we just have them delivered on a resupply mission. But when you’re in deep space, you don’t have that option; you have to have the ability to make all of the parts you might need, and without having a large stockpile of extra materials.”

According to NASA, the 3D printer can even recycle plastic items that are not usually linked with Earthbound 3D printers. For instance, almost all of the materials that are delivered to the station are packed using foam or plastic bags. Both can be loaded into the Refabricator to deliver items such as a plastic syringe, an eating utensil, or a custom-made wrench. That ability limits the amount of backup materials you need to take with you on a long-range expedition. After all, in space, space is at a premium.

For further information about 3D Printing, follow us on our social networks and subscribe to our newsletter

Would you like to subscribe to 3D Adept Mag? Would you like to be featured in the next issue of our digital magazine? Send us an email atcontact@3dadept.com

//pagead2.googlesyndication.com/pagead/js/adsbygoogle.js (adsbygoogle = window.adsbygoogle || []).push({});