EnvisonTEC: its two production ready 3D printers and its enterprise software suite

Two new models were unveiled this morning at Formnext, in Frankfurt (Germany) by the manufacturer of desktop and production 3D printers: the Perfactory 4 LED XXL and the family of high-speed Continuous Digital Light Manufacturing (cDLM) machines.

Both machines can be used for direct printing of final end-use parts, functional prototypes, manufacturing aids, molds and tooling, investment casting patterns, medical devices, such as hearing aids, commercial goods and more.

“Our larger new models will give our customers even more speed and throughput as DLP-style printing technologies continue their rapid growth in the 3D printing industry,” said CEO Al Siblani. “Because of our commitment to innovation and delivering value, EnvisionTEC’s 3D printing business is stronger than ever.”![]()

However, the main difference between the two of them is that the Perfactory model integrates a wide range of configurations with XY resolution down to 10 microns and can print the largest number of EnvisionTEC materials.

The cDLM family on the other hand comprises three desktop models that deliver build speeds ranging from 10 to 20 minutes per inch in Z across the entire build envelope.

The new Enterprise Software Suite

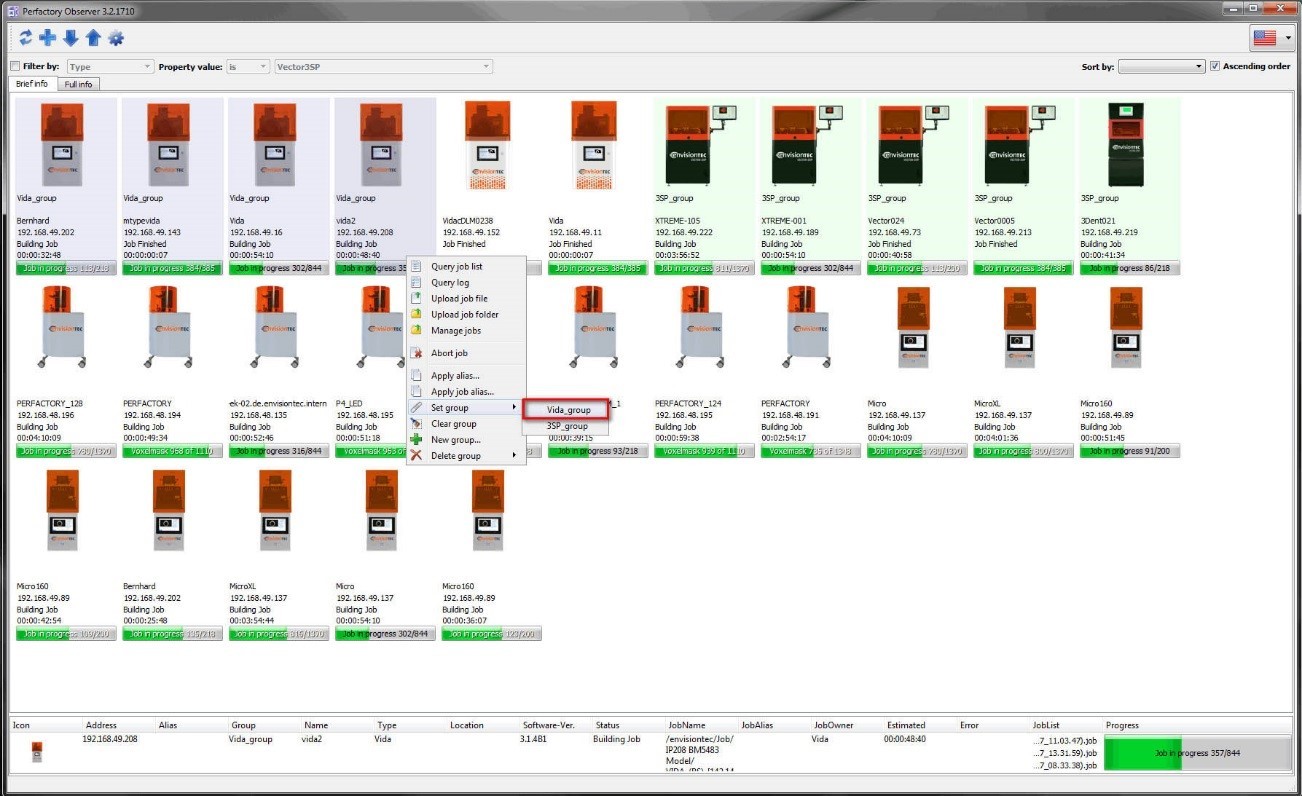

The international manufacturer improves its Perfactory Software Suite that allows users to prepare, monitor and manage print jobs on multiple 3D printers, among other benefits.

This new software suite will be very helpful to Desktop, 3SP, 3D-Bioplotter®, Viridis3D machines and the two new models mentioned earlier.

This new software suite will be very helpful to Desktop, 3SP, 3D-Bioplotter®, Viridis3D machines and the two new models mentioned earlier.

PSS 3.2, a new observer feature will identify EnvisionTEC 3D printers on a network by name and type, show a progress bar for each print job, with an estimated completion time, and allow users to rearrange and abort print jobs, in addition to other features.

“Our new software suite with Observer demonstrates that we are listening to customers and delivering the tools they need to continue 3D printing’s ultimate evolution to full production,” said CEO Al Siblani. “Our 3D printers have been used for mass customization production for more than a decade. Now, Observer will make it easier to manage a factory floor full of 3D printers processing multiple jobs.”

For further information about 3D Printing, follow us on our social networks and subscribe to our newsletter!

//pagead2.googlesyndication.com/pagead/js/adsbygoogle.js

(adsbygoogle = window.adsbygoogle || []).push({});