Home =

inspection time - search results

If you're not happy with the results, please do another search

DOSSIER | Qualification of 3D printed parts: What? Why? When? And most importantly how?

Once per year, we sit down to assess some of the key insights we collected from our conversations with OEMs using AM and from (potential) users of the technology at trade shows we visited....

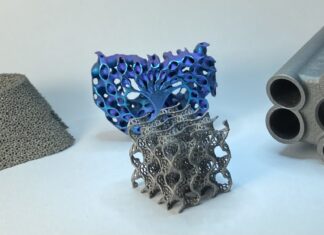

Identifying defects in metal 3D printed parts can lead to up to 70% savings in production costs. Materialise explains how and why.

As part of the additive production of a critical medical component, a defect identified after the post-processing phase made the team lose one HIP cycle, one day of post-processing and quality inspections, not to...

10 technology highlights of 2023 that shaped the Additive Manufacturing world (Part 2)

Updated on January 4th: The article has been updated to reflect the "Arburg" solution in part 4.

2023 has been a very interesting year both from a business and a technology perspective. Whether it was...

Download the November/December 2023 edition of 3D ADEPT Mag

« Shifting mindsets »

We’ve reached that time again… The end of the year is upon us and as usual, we reflect on what it means for the AM industry. In this last edition of 3D ADEPT...

Materialise continuous improvement process of its CO-AM platform sheds light on 4 developments

AM company Materialise continues to advance its open software platform CO-AM through partnerships with other AM technologies providers. As a reminder, the platform was created after Materialise acquired Link3D; it aims to provide AM users direct...

3DPRINTUK highlights the qualities of a good 3D printing bureau

The UK-based Additive Manufacturing company 3DPRINTUK underlines the difference between good and bad production bureau in 3D printing.

The company is a low-volume producer of 3D printed parts using powder bed fusion (PBF) 3D printing...

Updated: Large format Additive Manufacturing: Materials, Software and Costs

The article has been updated to reflect the fact that "most industrials often have in mind the use of machines with build volumes around 1 m3".

Most adopters of Additive Manufacturing (AM) share the same...

SAEKI, the latest newcomer in the AM market, focuses on automated factories

From lightweight carbon fibre elements to topologically optimised concrete floor slabs, SAEKI will focus on large scale applications across industries

Another newcomer showed up on our radar this morning: SAEKI, a Switzerland-based company that...

How do we use resin 3D printing materials in the healthcare industry? – Beyond dental applications

Among the wide range of 3D printing materials that can be used for medical devices, resins have often been harnessed and considered the materials of choice for dental applications. This was already considered a...

A look at the strategy that enables General Atomics Aeronautical Systems to reach beyond 75% of 3D printed parts in an aircraft.

With millions of dollars already saved in tooling, General Atomics Aeronautical Systems, Inc. (GA-ASI) shares the lessons-learned of their journey with industrial Additive Manufacturing. A meaningful example of their story relates to the completion...