Home =

inspection time - search results

If you're not happy with the results, please do another search

A new software algorithm helps to reduce inspection time for 3D printed nuclear parts by 85%

While inspection time for 3D parts may vary from one application to another, experts estimate that it can take around 25% of the total production time. That’s why, the more complex inspection processes are,...

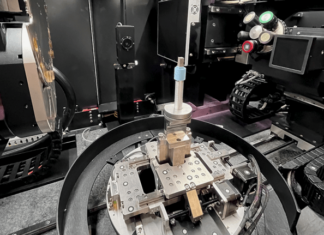

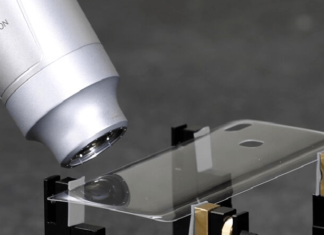

Hexagon reduces inspection time of delicate 3D printed parts with new precision non-contact CMM sensor

It is no secret that demanding industries such as medical or consumer electronics often require certification before the use of 3D printed parts in a given project. Several tools including measurement are often used...

Phase3D’s Early Adopter Program for 3D Printing Real-Time Inspection

Phase3D, a company that you previously discovered as Additive Monitoring Systems, now provides companies with the opportunity to access its in-situ inspection system for additive manufacturing (AM).

The patent-pending Project Fringe technology would go beyond...

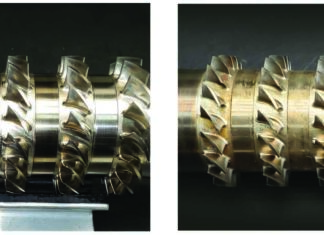

With LPBF, Upwing Energy moves from engineering design to full SCS compressor rotor assembly in just 10 weeks’ time

Through the integration of metal Additive Manufacturing into its processes, Upwing Energy, a gas technology service company, has optimized manufacturing time needed to support its Subsurface Compressor System's (SCS) gas well deployment schedules.

The patented...

ZEISS & ORNL sign licensing agreement for inspection of 3D printed parts

A licensing agreement between the Department of Energy’s Oak Ridge National Laboratory and manufacturer of multidimensional metrology solutions ZEISS will enable industrial X-ray computed tomography, or CT, to perform rapid evaluations of 3D-printed components...

Phase3D to develop a quality inspection system for cold spray Additive Manufacturing

Phase3D, previously known as Additive Monitoring Systems, has been awarded a 2-year $1.25 million contract from the Air Force Research Lab to develop a quality inspection system for cold spray AM (CSAM).

The company that...

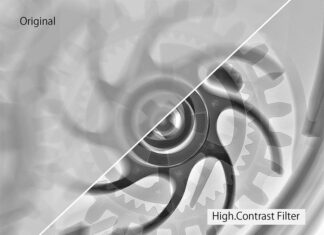

New Nikon filter enables to optimize X-ray inspection for castings, 3D printed components, or welds

Nikon's X-ray technology has the power to see cracks, voids and assembly defects but sometimes they can be hidden in high-density or low-contrast areas. Therefore, the Industrial Metrology Business Unit has developed a new filter that...

AddUp and Interspectral to work together on the reduction of Additive Manufacturing quality inspection costs

Industrial 3D printer manufacturer AddUp joins forces with software provider Interspectral to reduce quality inspection costs and enhance AM efficiency through a monitoring data visualization solution.

AddUp’s FormUp® 350 includes a monitoring suite, based on...

Quality Assurance Control | Metrology and Inspection for Additive Manufacturing

Additive Manufacturing is certainly the ideal manufacturing tool to fabricate components that one could not manufacture with conventional manufacturing processes but there is one thing we tend to forget: this technology does not benefit...

Protolabs announces detailed measurement and inspection reporting services in Europe

With the additional measurement and inspection services, Protolabs aims to complete the first one in order to meet specific customer requirements.