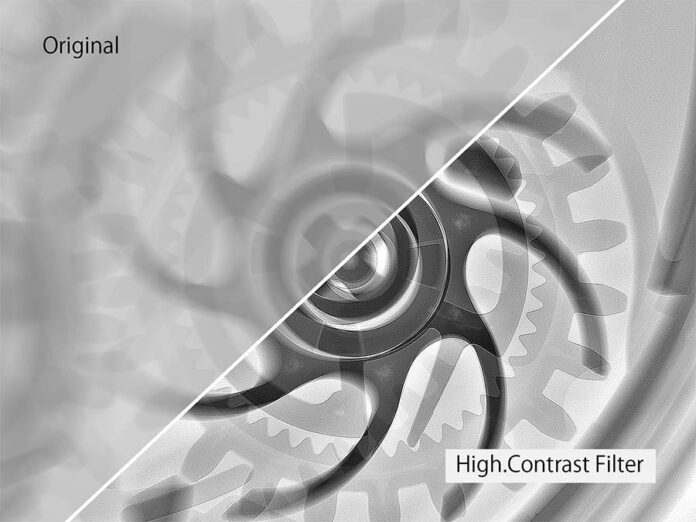

Nikon‘s X-ray technology has the power to see cracks, voids and assembly defects but sometimes they can be hidden in high-density or low-contrast areas. Therefore, the Industrial Metrology Business Unit has developed a new filter that enhances the contrast in images produced by its X-ray inspection machines: High.Contrast Filter.

Typically, visualising features in high-density areas of a radiograph involves increasing the brightness of the whole image, which risks overexposing the lower-density areas. The strength of High.Contrast Filter is that it can normalize the contrast across the whole image, revealing detail in high-density regions without washing out those of lower density.

Due to advanced contrast and sharpness enhancements, the High.Contrast Filter provides image quality for both high and low contrast areas in a single, clear image. Now, an operator can visualize all aspects of the sample more quickly than ever before, optimizing and increasing their inspection throughput.

The principal application is quality control of PCBAs (printed circuit board assemblies) and other electronic circuitry such as BGAs (ball grid arrays), capacitors and through-holes.

Its power may be used equally well in mechanical engineering for non-destructive examination of castings, 3D-printed components, or welds, and for failure analysis of assemblies such as inhalers in the medical industry.

The High.Contrast Filter has innovative processing capability for use within Nikon’s automated inspection programs and C.Clear real-time imaging engine. The latter intelligently adapts to changing X-ray conditions and variations in sample position, automatically adjusting parameters to provide clear radiographs. With their powerful microfocus sources and industry-leading detectors with high dynamic range, Nikon’s X-ray machines have always been able to capture the smallest defects in raw radiographs. With the new filter, contrast and sharpness are taken to the next level, revealing in much starker detail any voids, cracks and other flaws that may be present.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter: Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure you send it to contact@3dadept.com