Phase3D, a company that you previously discovered as Additive Monitoring Systems, now provides companies with the opportunity to access its in-situ inspection system for additive manufacturing (AM).

The patent-pending Project Fringe technology would go beyond monitoring via in-situ inspection of each powder layer in the 3D printing processes. “At Phase3D, we’ve created a real-time inspection system using rapid height measurement technology to detect and classify process anomalies during 3D printing,” explains Niall O’Dowd, PhD, Founder and CEO of Phase3D. “Our goal is to reduce the cost per part in AM by shifting the paradigm from in-situ monitoring (i.e., identifying outliers) to in-situ inspection, a repeatable quality and certification system based on direct measurement.”

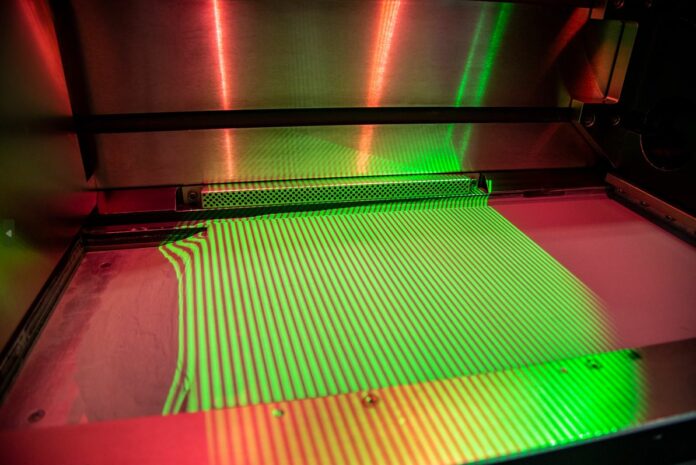

Project Fringe

Project Fringe is a proprietary structured light technology that measures any powder-based AM process. The real-time data creates detailed measurements for where and when a print anomaly occurs. Project Fringe presents data in 3D, enabling users to see a multitude of print anomalies in real-time. To date, Phase3D is compatible with 3D printers including the EOS M 290, ExOne/Desktop Metal Innovent, Concept Laser M2, Renishaw AM400, and DMG MORI LASERTEC 30. Additional 3D printers can be retrofitted based on individual customer demand.

As a reminder, the company was recently selected by NASA’s Marshall Space Flight Center (MSFC) in a Collaborative Agreement Note to develop and integrate in-situ monitoring technology for additive manufacturing (AM) into on-site production powder bed fusion 3D printers.

“After validating the technology with partners at NASA, the Air Force Research Lab, and several Department of Energy labs, we are excited to unveil the Early Adopter Program this February. We are offering our inspection tool to manufacturers for a greatly reduced software fee, in exchange for data exchange,” Dr. O’Dowd says.

The Early Adopter Program includes hands-on time with the Phase3D team to initialize Project Fringe on-site, retrofit installed printers, and keep up and running via monthly software license.

Available for inquiry now, the Early Adopter Program is set to superpower customer operations. Limited space is available in the program, which will offer early access and reduced pricing structures for commercial installation of Project Fringe.

The Early Adopter Program is targeting production-oriented businesses that have in-house powder bed fusion or binder jetting systems.

The hardware-and-software package will:

- Attach to any powder bed-based 3D printer

- Detect defects in real time throughout all print cycles

Remember, you can post jobopportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com