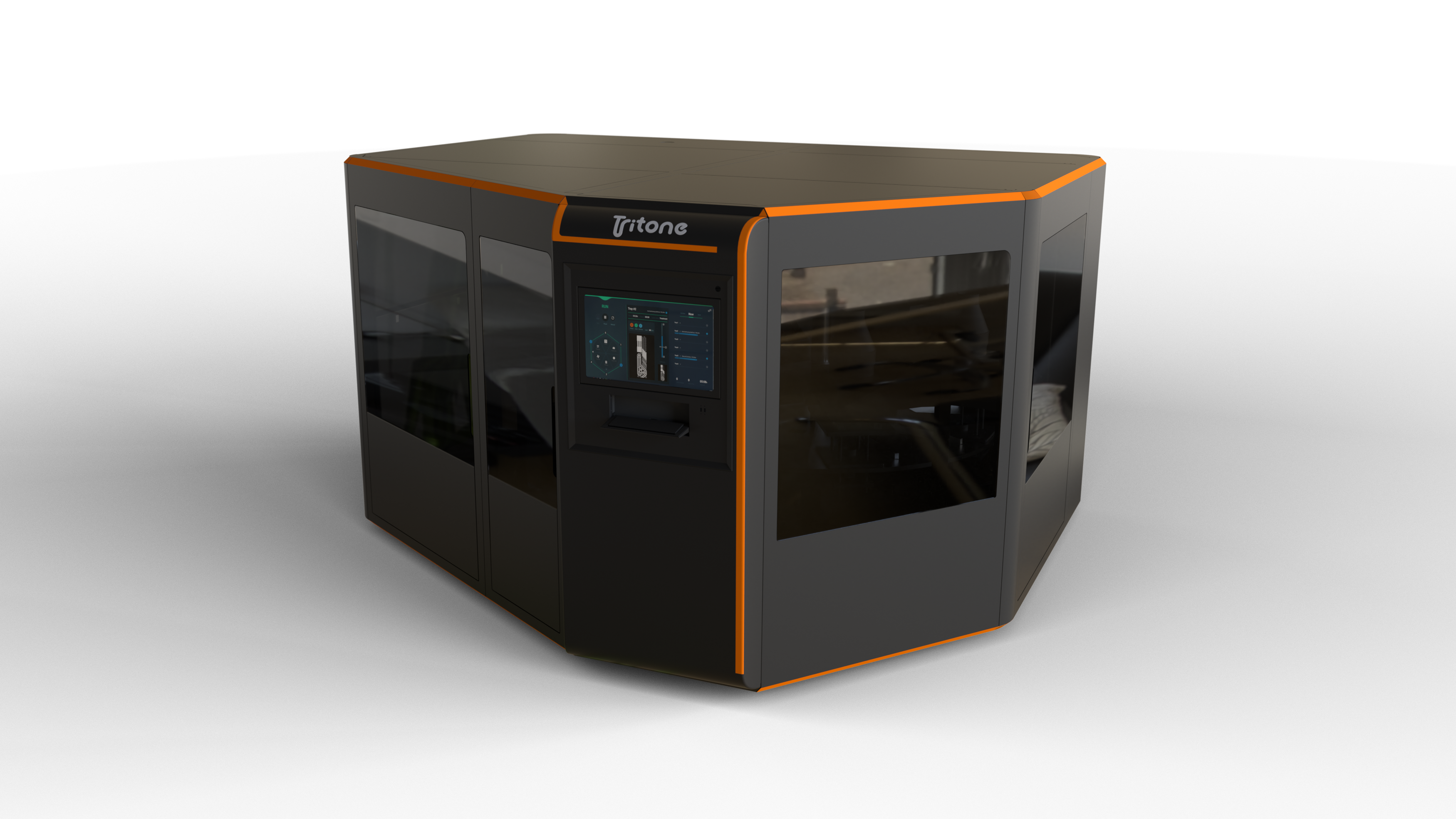

Among the new wave of additive manufacturing newcomers that we recently identified at Formnext 2019, there is Tritone Technologies, an Israël-based company that designs and manufactures an industrial solution called DOMINANT.

With a provocative name that aims to underline its ability to meet the stringent requirements of demanding industries, DOMINANT first impresses by its size. The metal AM technology makes its debut on a market that believes in the potential of metal additive manufacturing. As a matter of fact, the recent report from Ampower predicts an annual grow of 24% of this market share (3D ADEPT Mag, Nov. Issue PP 30-31).

When we look at the various technologies that have already a clear footprint on the market, we cannot help but question the reasons that make Tritone’s DOMINANT outstanding. That’s why we invited Ofer Ben-Zur in this Opinion of the Week series.

Ofer Ben-Zur is the CEO and co-founder of Tritone Technologies, a start-up of three years old. With over 20 years of R&D and senior management roles in the Digital printing industry, Ben-Zur brings an experience that many do not have in this market.

Just like 2D Digital Printing Companies such as Mimaki and HP, Ben-Zur believes that 3D Printing results from developments of the 2D Digital Printing technique and that this revolution should inspire and lead to practical innovations in the metal manufacturing world.

While relying on this experience, and backed by a strong team, Ben-Zur developed a patented technology named MoldJet™. According to the co-founder, the technology can print any MIM based powder including metal and ceramic materials.

So far, only a few companies highlight this ability to process both types of materials. When asked what enables Tritone’s technology to stand out from the crowd, the CEO replied:

“We believe we have a few unique advantages which differentiate us from other technologies in the market. First, we keep a safe and clean industrial environment by utilising a powder-free process using metal or ceramic paste in sealed cartridges. Second, we offer a wide range of materials that can be easily changed between jobs in an industrial manufacturing throughput of 1600cc/hr. Our MoldJet™ technology enables an accurate print of big and small parts with fine detail and high surface quality.”

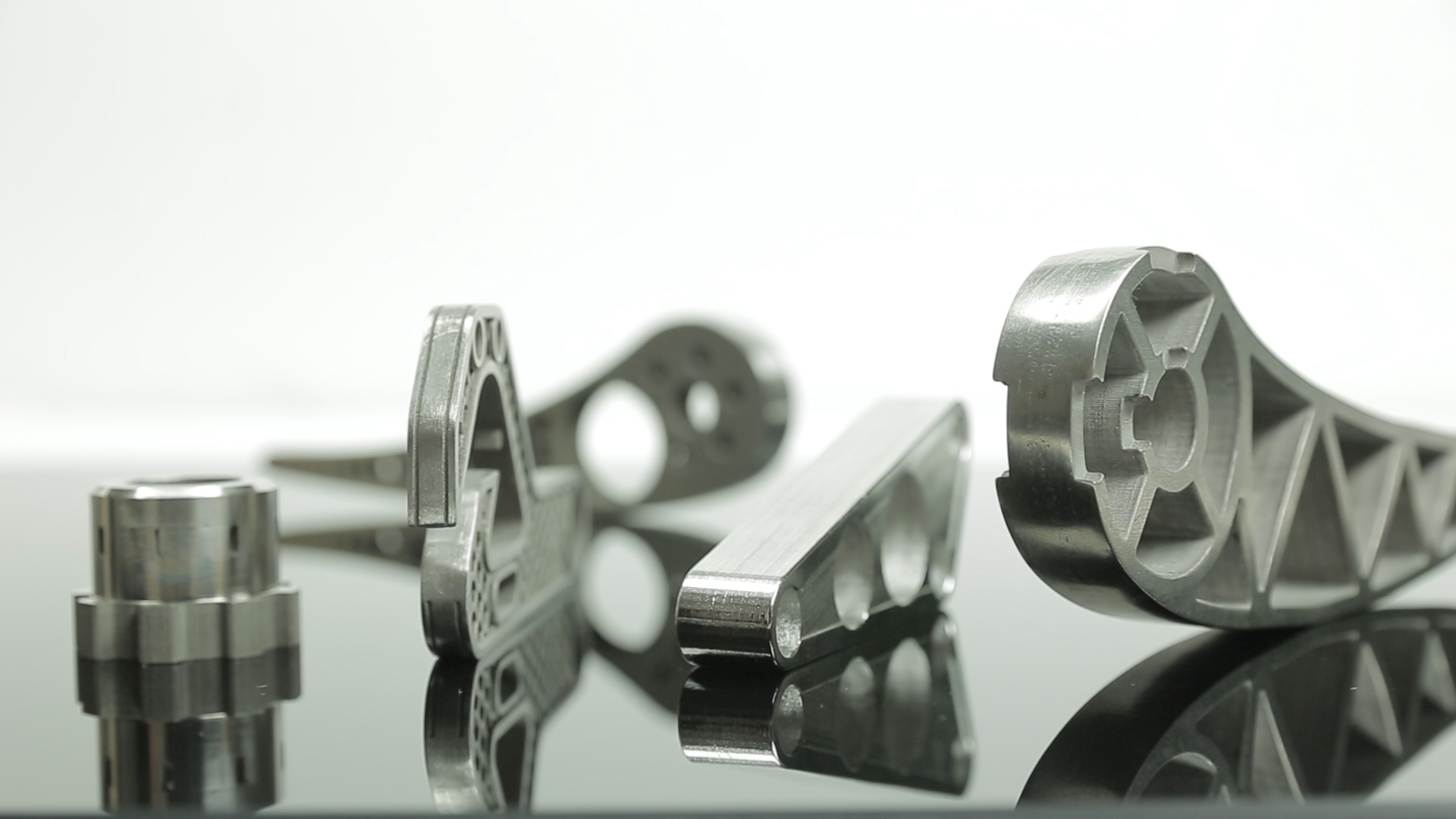

Furthermore, apart from ceramic materials, and speaking about key metals the machine can process, Tritone’s spokesperson mentions the system’s ability to process over 10 different materials including stainless steels, titanium, tool steels, bronze, copper and alumina. Materials that you have certainly already seen if you stopped by the company’s booth at Formnext 2019. With regards to the few parts that we saw at the company’s booth in Frankfurt, the machine delivers a pretty good resolution.

Moreover, the great advantage of these materials is that they are available at affordable price.

In addition, during the manufacturing process, the operator might expect real time verification and quality control of each layer.

At the end of the manufacturing process, comes the post-production stage. As this stage increasingly raises several concerns for industrials, it would have tough to not ask how the operator can handle it. Ofer Ben-Zur therefore comments:

“After the printing process we transfer the printing tray into an ultrasonic bath in order to remove the support material. After this stage, the parts go through a sintering process which gives them their material characteristics. As our “green parts” are very dense and robust, it is very easy to handle them and achieve a very high density of 99% after sintering.”

What’s in the pipeline now?

Following a successful debut at Formnext where they received positive feedback from those who saw their Alfa machine, Tritone Technologies will focus on Beta customers throughout 2020 and the preparation of the official launch of the DOMINANT. With a dedicated team that is committed to achieving the company’s vision, 2020 promises to be exciting; not to mention that the company already announces that a few surprises will await visitors at Formnext 2020.

Lastly, one thing is certain, Tritone is bringing something that will raise curiosity from fellow companies and answer specific concerns from industrials.

Remember, you can post free of charge job opportunities in the AM Industry on 3D ADEPT Media or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com. Happy New Year!