Meta Reality Labs unveils the Digital Twin catalog

Meta Reality Labs Research is debuting the Digital Twin catalog, a dataset for 3D object models, for 3D reconstruction. This collection encompasses over 2,400...

3D Systems gets FDA clearance for Monolithic Jetted Denture Solution

On the heels of an FDA clearance for 3D printed PEEK cranial implants, OEM 3D Systems got clearance from the Food & Drug Administration...

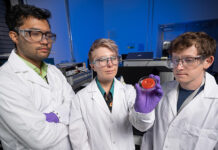

LLNL brings a new approach to 3D printing with microwave technology

Lawrence Livermore National Laboratory (LLNL) brings a novel approach to 3D printing with microwave technology. Microwave Volumetric Additive Manufacturing (MVAM) is a technique that...

Use of a new biopolymer nanocomposite for 3D printing bone grafts

The latest biopolymer nanocomposite material for bone grafts has been developed at the University of Waterloo. The University of Waterloo focused on offering optimal...

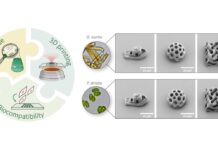

Researchers develop biocompatible materials from microalgae

Researchers from Heidelberg University in Germany have fabricated inks for printing complex biocompatible 3D microstructures from the raw materials extracted from the microalgae.

Being led...

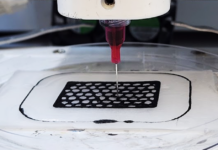

New 3D printing technique uses a polymer ink and salt water solution to create parts

3D printing is undergoing a paradigm shift with the development of the PNIPAM method. This method developed by researchers at The University of California...

Callier Center relies on 3D printing to manufacture hearing aid earmolds

The Callier Center for Communication Disorders at the University of Texas at Dallas kickstarted manufacturing 3D printed custom earmolds for pediatric hearing aids.

This lab...

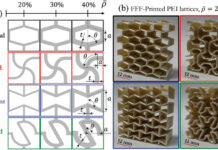

UK Researchers relied on the “enhancement factor” to develop 3D-printed lattices with advanced properties

Engineers in the UK and Italy are behind the research on the deformation mechanisms of 3D printed materials. The latter aims to provide insight...

ASICS and Dassault Systèmes provide on-demand insoles personalized for individual foot shape

Shoe manufacturer ASICS and software developer Dassault Systèmes have jointly opened a test studio near Paris that will serve as a pilot test for...

UniSA opens new metal 3D printing facility, provides updates on 4 projects worth over $18M

University of South Australia (UniSA) recently celebrated the opening of a new Advanced Manufacturing facility and revealed significant industry investment in four space research...