When they say, 3D printing can help create “anything”, this might actually be true. We have witnessed the possibility of 3D printing to process all types of materials from wood, to glass but this one is a premiere for the research industry.

New research from Carnegie Mellon University shows the possibility of using 3D ice printing to help create structures that resemble blood vessels in the body.

The results of this research – if successful, could help fill the gap between the availability of organs and the demand for transplants. The truth is, if you only look at statistics in the USA, over 100,000 individuals in the United States are currently in need of organ transplants. The demand for organs, such as hearts, kidneys, and livers, far exceeds the available supply and people sometimes wait years to receive a donated organ. Approximately 6,000 Americans die while waiting each year. Imagine what this number would be for the rest of the world.

With tissue engineering, it would be possible to create lab-grown organs and tissues that could meet this demand. The only thing is, creating blood vessel networks in artificial organs that work like natural ones, from tiny capillaries to larger arteries is the Holy Grail because traditional artificial blood vessel designs often don’t mimic the natural design needed to function properly in the body.

The idea that consists in using 3D ice printing

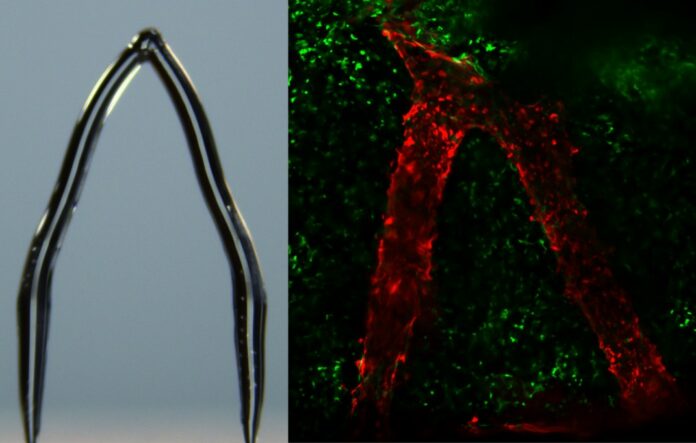

3D ice printing generally involves adding a stream of water to a very cold surface. “What makes our method different from other kinds of 3D printing is that instead of letting the water completely freeze while we’re printing, we let it maintain a liquid phase on top. This continuous process, which is what we call freeform, helps us to get a very smooth structure. We don’t have a layering effect typical with many 3D printing,” Feimo Yang, lead researcher, explained.

Researchers also used heavy water, a form of water where the hydrogen atoms are replaced by deuterium, which gives the water a higher freezing point, and helps create the smooth structure.

These 3D-printed ice templates are then embedded in a gelatin material, GelMA. When exposed to UV light, the gelatin hardens, and the ice melts away, leaving behind realistic blood vessel channels.

The researchers successfully demonstrated that they could introduce endothelial cells, like those in blood vessels, into the fabricated blood vessels. The cells survived on the gelatin for up to two weeks. (In the future, they intend to culture those cells for a longer duration.)

In addition to potential use for organ transplant, Yang points out that 3D printed blood vessels could be used for testing the effects of drugs on blood vessels. They could also be coated with a patient’s own cells to see how the cells respond to a drug treatment before giving it to the patient.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media for free or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter: Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure you send it to contact@3dadept.com