Across the world, several organizations have been exploring the use of 3D printing for breast implants. While several developments are still in progress, the common thread across these research projects is to provide personalized, precise, and accessible solutions.

Researchers from the University of East Anglia (UEA) are the latest research team that has decided to explore the use of 3D printing for breast reconstruction and breast-conserving surgeries – as part of a proof-of-concept project funded by UEA Health and Social Care Partners (UEAHSCP).

How can 3D printing be used to create personalized surgical aids for breast reconstruction surgery and breast implants for breast-conserving surgery?

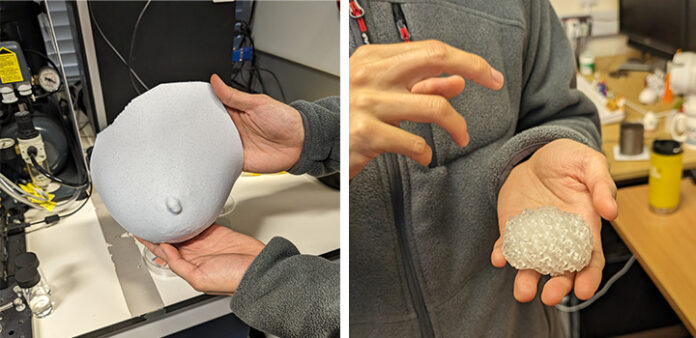

The research team used a 3D scanner to capture the patient’s breast shape before the breast reconstruction surgery, to create a mold using the 3D printer. This personalized mold can be used as a surgical aid to measure the volume of the patient’s own tissue and shape for breast reconstruction, aiming to improve the quality and speed of the surgery.

The other aspect of the project involved using patient’s MRI data to create a personalized implant, which was 3D-printed using a biodegradable polymer, for breast-conserving surgery: an operation that aims to remove the cancer while keeping as much of the breast tissue and shape as possible. Once printed, the 3D scaffold implant would be placed into a patient’s breast during surgery, with the patient’s fat injected into it, with the implant then degrading in the body slowly over time.

Normally, conventional breast reconstruction requires one or more correction surgeries after the initial operation to achieve the satisfactory shape of the breast of the patient. The personalized breast mold aims to improve the accuracy of the surgery and minimize the need for multiple surgeries, which will not only reduce the theatre time needed for each patient but also improve the clinical outcome and patient satisfaction.

While the technology is currently under development, the potential for this project is vast. Most notably, Norfolk and Norwich University Hospital (NNUH) currently outsources its 3D printing services for some patients’ cases in which personalized surgical aid, tools, and surgical planning models are needed. Working in partnership with our regional Trusts, establishing a regional medical 3D printing service in Norfolk could help to significantly reduce emissions and wider environmental impacts by reducing the need to outsource the 3D printing overseas, making significant cost-savings for the regional Trusts, researchers said.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com